Yarn pulp compaction equipment for production of corrosion-resistant glass fiber reinforced plastic grating

A fiberglass and corrosion-resistant technology, which is applied in the field of pulp compaction equipment for corrosion-resistant FRP grating production, can solve the problems of insufficient compaction strength, different content, uneven mortar mixing, etc., to reduce manpower burden, improve low efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

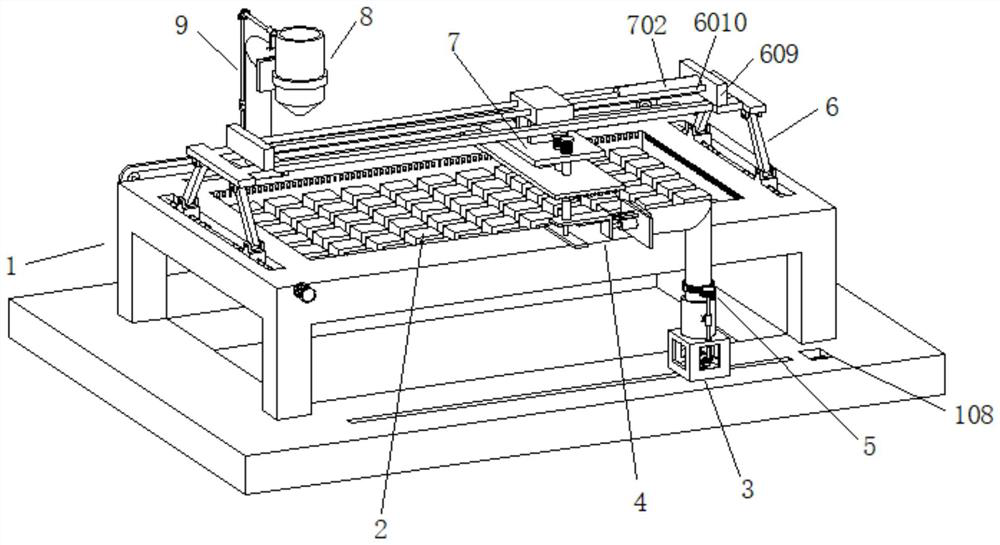

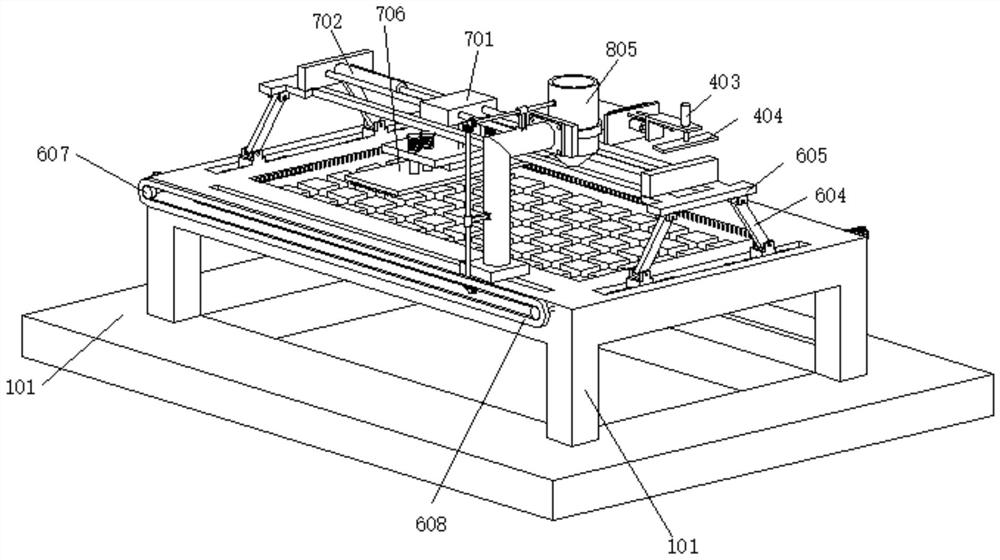

[0054] Embodiment 1 discloses a yarn slurry compaction equipment for the production of corrosion-resistant glass fiber reinforced plastic gratings, refer to the appendix. figure 1 and attached figure 2 , including the base 1 as the load-bearing main body, the front and rear sides of the base 1 are symmetrically provided with a homogenizing device 4 and a feeding device 8, a compaction device 7 is provided above the base 1, and the bottom of the homogenizing device 4 is subject to the moving device 3 and the steering The device 5 is driven, the bottom of the feeding device 8 is provided with a synchronous transmission anti-condensation device 9, and the two ends of the compaction device 7 are provided with a lifting device 6;

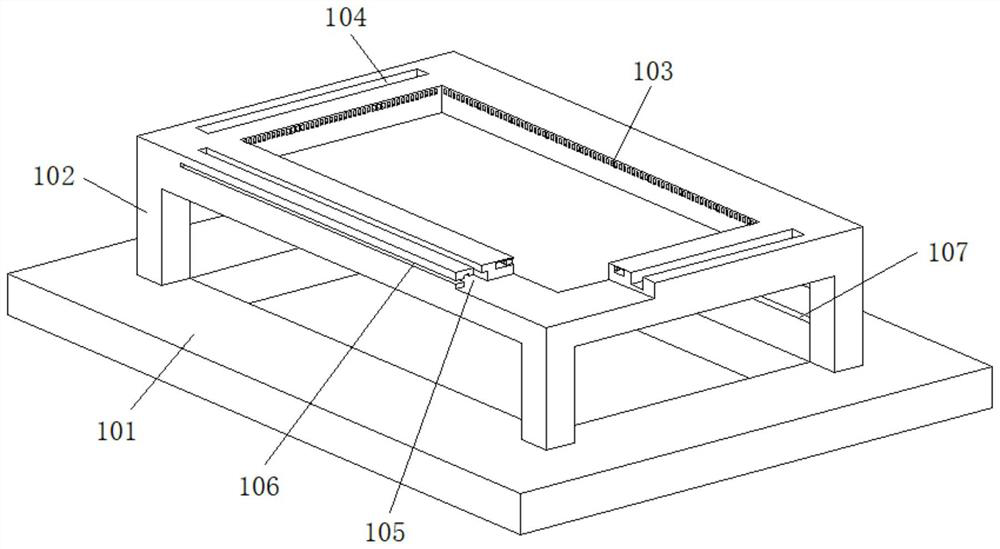

[0055] Reference attached image 3 , the base 1 is composed of a base 101 in an up-down structure and an operating table 102. A module 2 is embedded in the top of the operating table 101, and a liquid return hole 103 is evenly arranged around the modul...

Embodiment 2

[0064] Example 2 is slightly modified on the basis of Example 1, and the same points will not be repeated. The difference is that a feeding device 8 and an anti-coagulation device 9 for preventing the coagulation of the slurry are added. Refer to the appendix. Figure 9 and attached Figure 10 , the feeding device 8 includes a second screw rod 801 arranged in the chute one 105, the second screw rod 801 is screwed with a third thread seat 802, the top of the third thread seat 802 is provided with a fixed column 803, and the front end of the fixed column 803 A barrel 805 is installed through the positioning ring 804, and a flow valve is installed at the outlet of the barrel 8;

[0065] The anti-condensation device 9 includes a transmission gear 901 installed on one side of the third threaded seat 802 , a rack 902 is fixedly installed under the transmission gear 901 , and the transmission gear 901 rotates synchronously with the third bevel gear 904 through the connecting shaft 90...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com