Degradable fiber, fracturing fluid with same and method for preparing fracturing fluid

A technology for degrading fibers and fracturing fluids, applied in chemical instruments and methods, and drilling compositions, etc., can solve the problems of insufficient sand-carrying capacity of fracturing fluid, large amount of fracturing fluid thickener, and gel breaking of fracturing fluid Incomplete and other problems, to achieve the effect of reducing the amount of thickener, reducing the amount of thickener, and avoiding premature settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

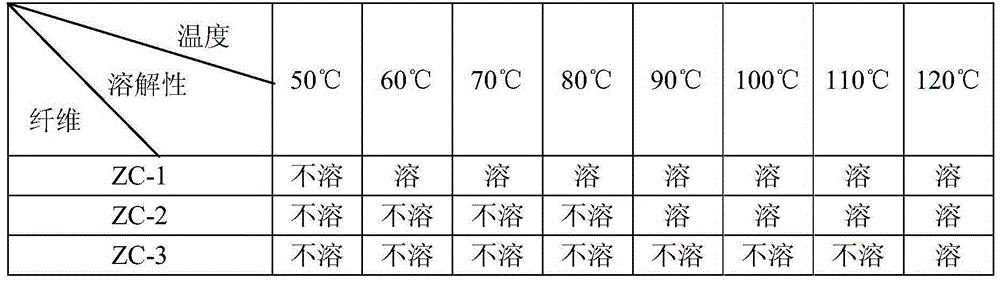

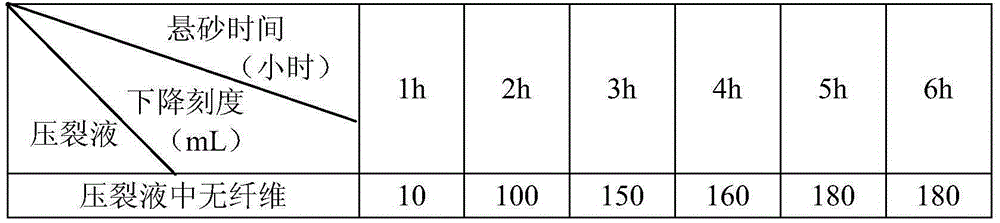

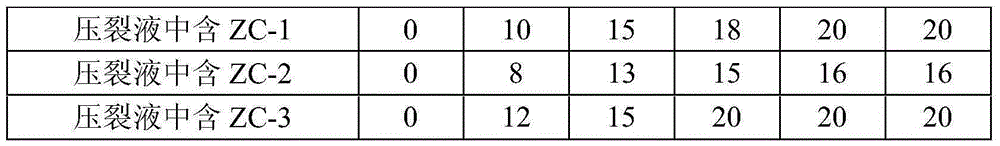

[0026] This embodiment provides a degradable fiber, based on the total weight of the degradable fiber, it is by making 55% of 2-hydroxypropionic acid and 45% of glycerol polymerized at 170 ° C for 4 hours A polymer is obtained, and then the polymer is prepared by jetting, winding, drawing, rewinding, and shearing in sequence, which is recorded as fiber ZC-1, with a length of 0.6 cm and a diameter of 80 μm. It can meet the needs of fracturing construction at 60°C.

Embodiment 2

[0028] This embodiment provides a kind of degradable fiber, based on the total weight of the degradable fiber, it is by making 60% of 2-hydroxypropionic acid and 40% of ethylene glycol carry out polymerization reaction at 170 ℃ for 5 hours A polymer is obtained, and then the polymer is prepared by jetting, winding, drawing, rewinding, and shearing in sequence, which is recorded as fiber ZC-2, with a length of 0.6 cm and a diameter of 80 μm. It can meet the demands of 90°C fracturing construction.

Embodiment 3

[0030] This embodiment provides a kind of degradable fiber, based on the total weight of the degradable fiber, it is by making 70% of 2-hydroxypropionic acid and 30% of ethylene glycol carry out polymerization reaction at 170 ° C for 3 hours A polymer is obtained, and then the polymer is prepared by jetting, winding, drawing, rewinding, and shearing in sequence, which is recorded as fiber ZC-3, with a length of 0.6 cm and a diameter of 80 μm. It can meet the needs of fracturing construction at 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com