Monitoring structure for preventing stirring and granulating air-tight seal air path from being blocked

An air-tight and air-path technology, which is applied in the methods of granulating raw materials, measuring devices, granulation in static tanks/tanks, etc., can solve the problem that the staff is difficult to find the air circuit, loss, etc., and whether the convenience is normal or not. The effect of moving and preventing abnormal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

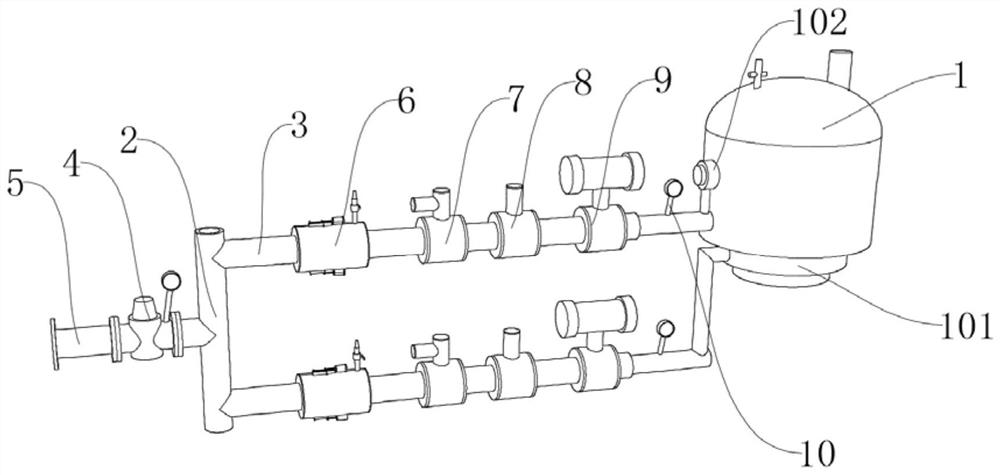

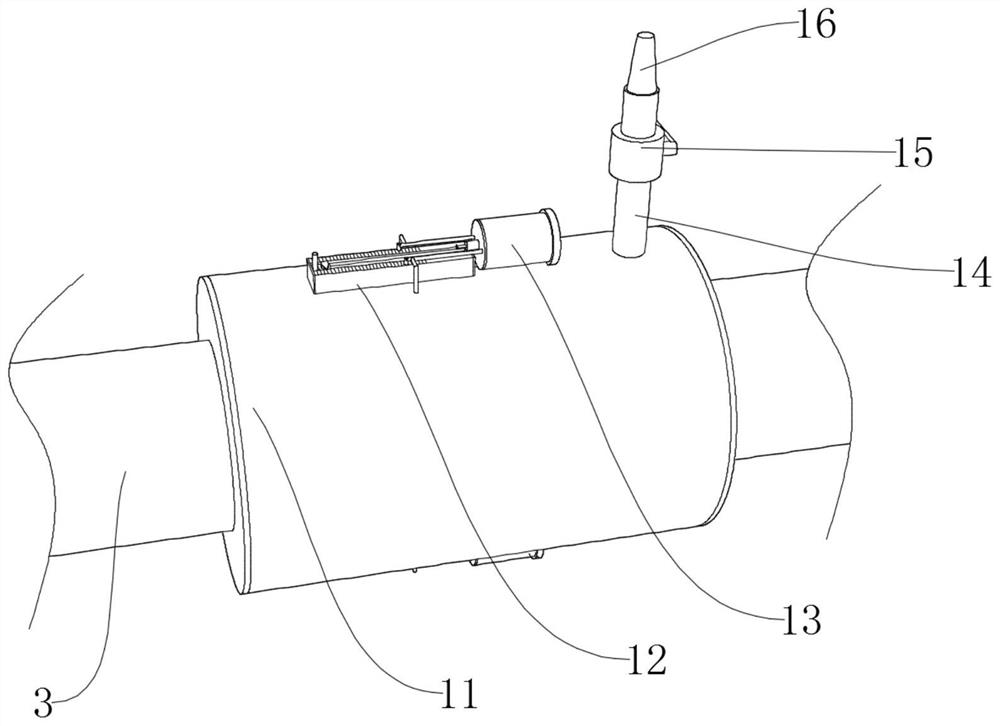

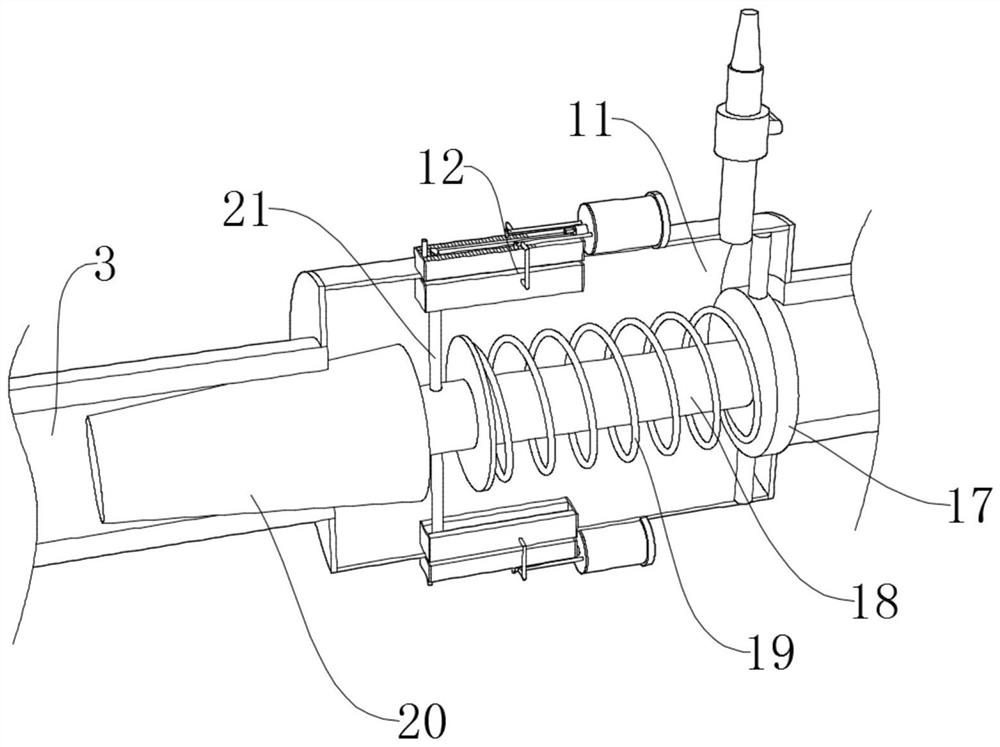

[0030] refer to Figure 1-Figure 5 , a monitoring structure for preventing the blockage of air sealing of stirring and granulating, including a communication pipe 2, a stirring part 101 and a granulating part 102 used by the granulator 1 and the granulator 1, and two gas outlet ends of the communication pipe 2 Two bronchial tubes 3 are fixedly connected, and the two bronchial tubes 3 have the same structure. The bronchial tubes 3 are provided with a monitoring mechanism 6. The monitoring mechanism 6 includes a fixed cylinder 11 that is fixedly communicated with the bronchial tubes 3. The circumferential inner wall of the fixed cylinder 11 is fixed with a guide sleeve 17 by bolts. , the guide sleeve 17 is inserted with an insertion rod 18, and the end of the insertion rod 18 away from the guide sleeve 17 is fixed with a plug 20 by bolts, and the plug 20 passes through the fixing cylinder 11 and contacts with the bronchus 3, and the circumferential outer wall of the insertion rod...

Embodiment 2

[0034] refer to Figure 1-Figure 5, the present invention provides a new technical solution: a monitoring structure for preventing the blockage of the air-sealed air path of stirring and granulation, including a communication pipe 2, a granulator 1 and a stirring part 101 and a granulating part used by the granulator 1 102, the two air outlets of the communication pipe 2 are fixedly connected with two bronchi 3, the two bronchi 3 have the same structure, the air inlet end of the communication pipe 2 is fixed with a pressure reducing valve 4 by bolts, and the pressure reducing valve 4 can stabilize the air pressure, The other end of the pressure reducing valve 4 is fixed with the main trachea 5 by bolts. When in use, the main trachea 5 needs to be connected with the air source. The bronchus 3 is provided with a solenoid valve 7 and a throttle valve 8, and the throttle valve 8 is used to control the bronchus 3. The gas flow in the bronchus 3 is provided with a flow sensor 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com