Method for creating digital twinning of facility or device

A facility, digital technology, applied in general control system, comprehensive factory control, program control, etc., can solve problems such as manual assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

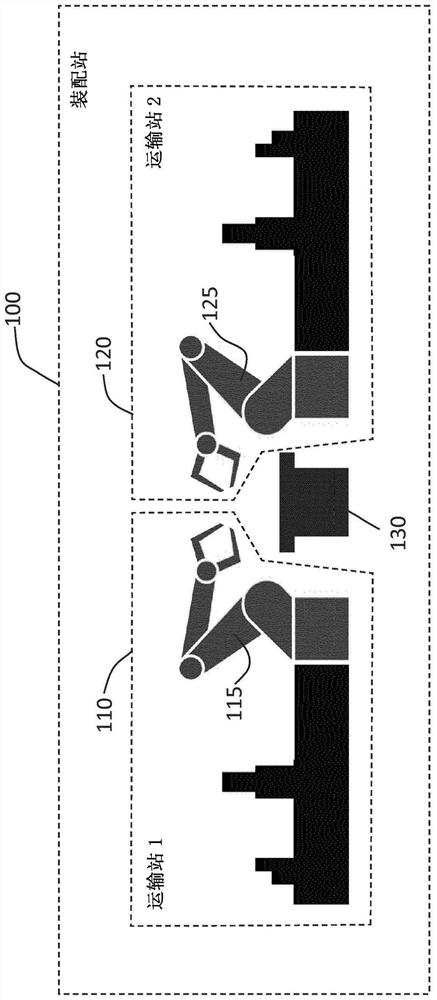

[0291] figure 1 An assembly station 100 or assembly unit 100 with a first transport station 110 and a second transport station 120 is shown. The first transport station 110 includes a first robotic unit 115 and the second transport station 120 includes a second robotic unit 125 . Assembly station 100 also includes assembly platform 130 .

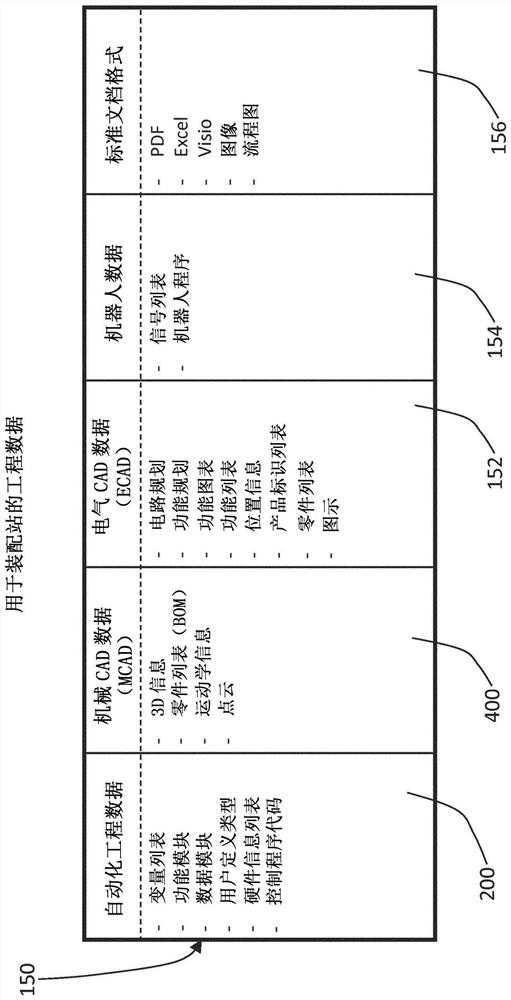

[0292] figure 2 shown for figure 1 List of engineering data 150 for assembly station 100 shown in . Engineering data 150 here includes automation engineering data 200 , mechanical CAD data (MCAD) 400 , electrical CAD data (ECAD) 152 , robotics data 154 and data 156 in standard document formats.

[0293] In this context, the automation engineering data 200 include data required or used in the context of the automation of the assembly station 100 , for example by means of suitable controllers or control devices (eg, one or more programmable logic controllers).

[0294] Such data is, for example, a variable list of variables used within t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com