Working cylinder

A technology of working cylinder and working cavity, applied in manufacturing tools, workpiece edge parts, metal processing equipment, etc., can solve problems such as limiting the service life of threads, loosening screw connections, and high time investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

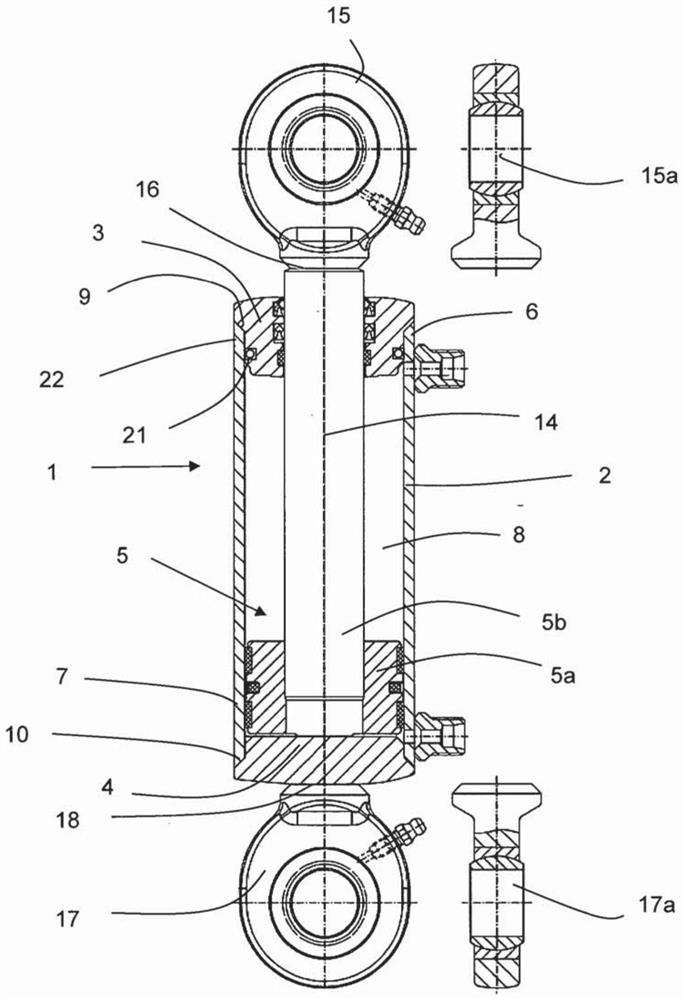

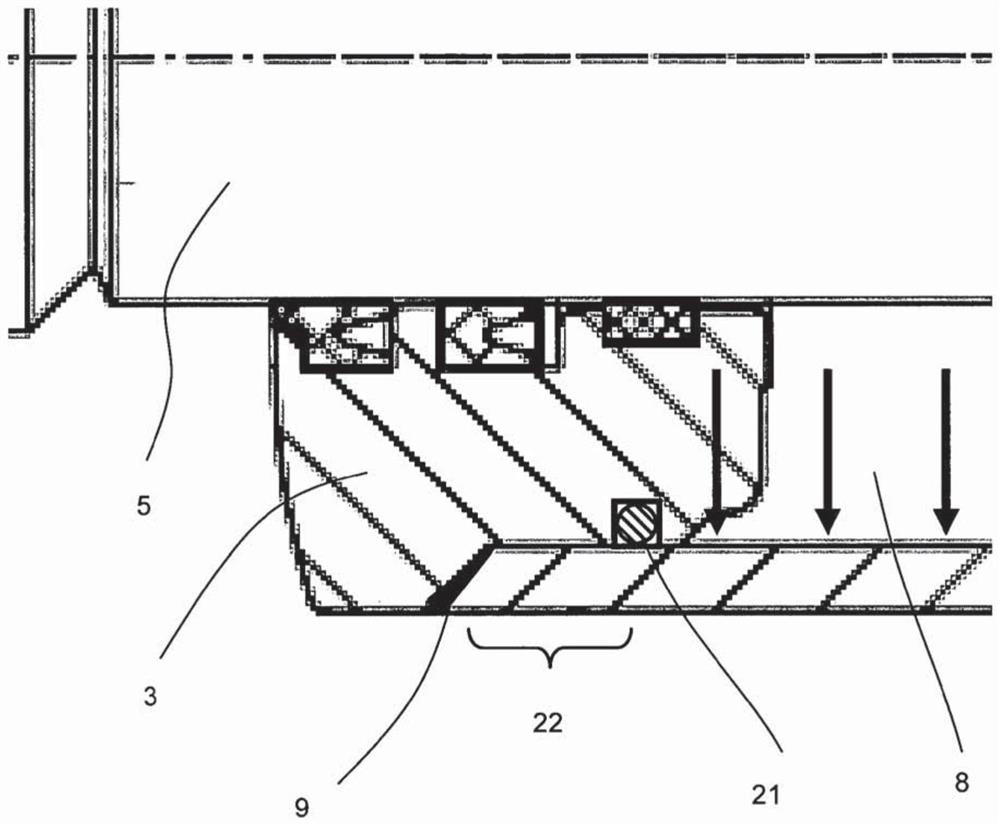

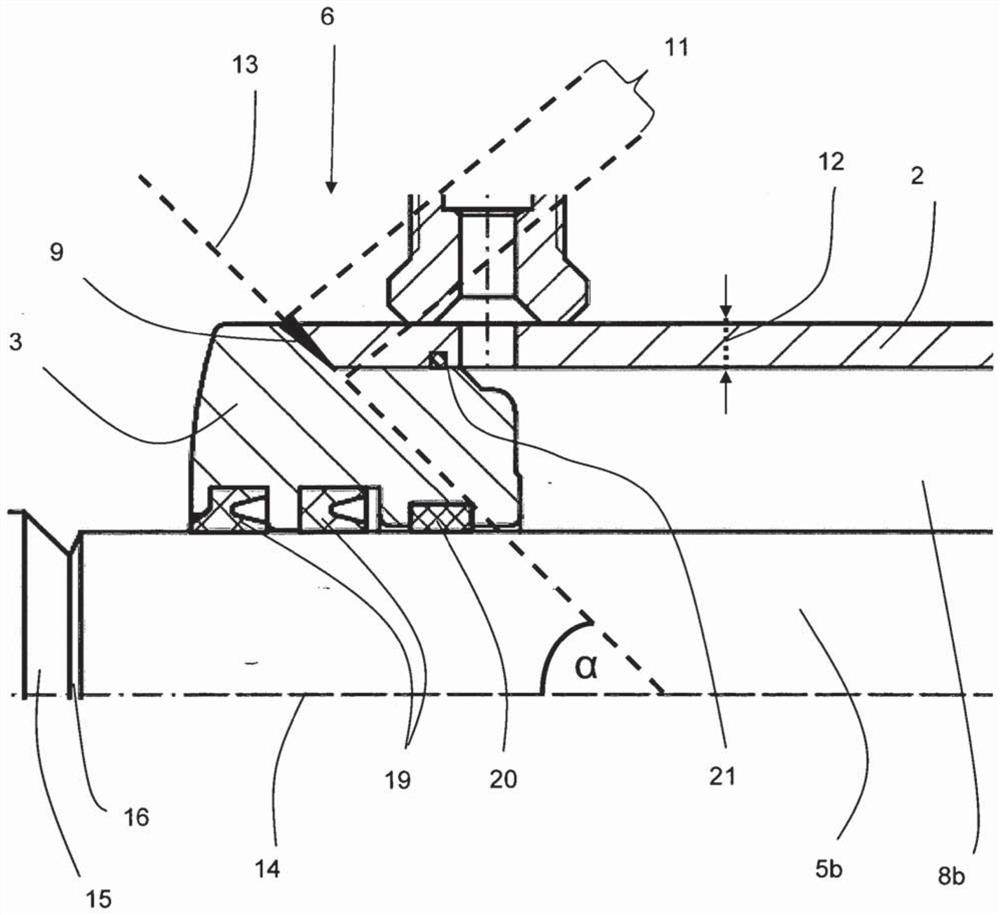

[0091] figure 1 An overview illustration of an embodiment of a working cylinder 1 as a differential working cylinder is shown. The working cylinder 1 has the cylinder liner 2 , the first closing part 3 , here designed as a guide closing part, the second closing part 4 , here designed as a bottom closing part, and the piston unit 5 . The piston unit 5 is constituted by the piston 5a and the piston rod 5b.

[0092] In this embodiment, the fixing module 15 on the piston rod side is arranged on the piston rod 5b and the fixing module 17 on the bottom side is arranged on the second closing part 4 which is designed as a bottom closing part. The two fixing modules 15 , 17 are respectively assigned fixing pins 15 a, 17 a. Said fixing modules 15, 17 and fixing pins 15a, 17a are not part of the present invention and are only shown for a better overview.

[0093] The piston unit 5 is arranged in the cylinder interior 8 in relation to the piston 5a and by means of the piston rod 5b, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com