Flexible contact network state monitoring system

A condition monitoring system, catenary technology, applied in transmission systems, system integration technology, measuring devices, etc., can solve the problems of complex monitoring process, high monitoring cost, inability to distinguish faults, etc., to achieve accurate monitoring results and improve inspection efficiency , the effect of good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

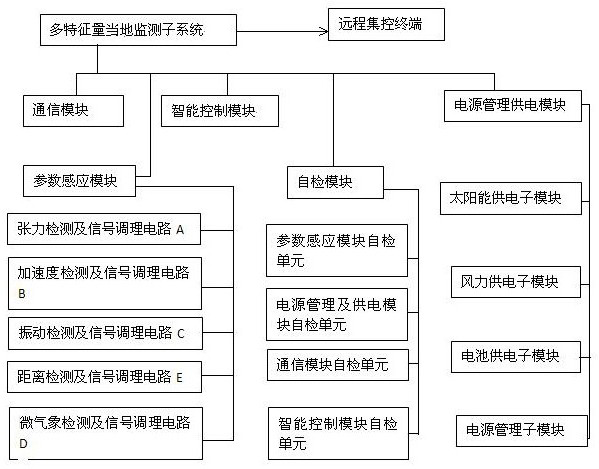

[0017] figure 1 As shown, a flexible catenary state monitoring system includes a multi-feature local monitoring subsystem and a remote centralized control terminal. The multi-feature local monitoring subsystems have the same multiple sets; each set of multi-feature local monitoring subsystems includes electrical A parameter sensing module, an intelligent control module, a communication module, a power management power supply module, a self-checking module, and multiple sets of local monitoring subsystems with multiple characteristics are respectively installed at the compensation device of the catenary anchor; the parameter sensing module includes Electrically connected tension detection and signal conditioning circuit A, acceleration detection and signal conditioning circuit B, vibration detection and signal conditioning circuit C, micro-meteorological detection and signal conditioning circuit D, distance detection and signal conditioning circuit E; the self-checking module in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com