Energy-saving water mixing heat supply unit

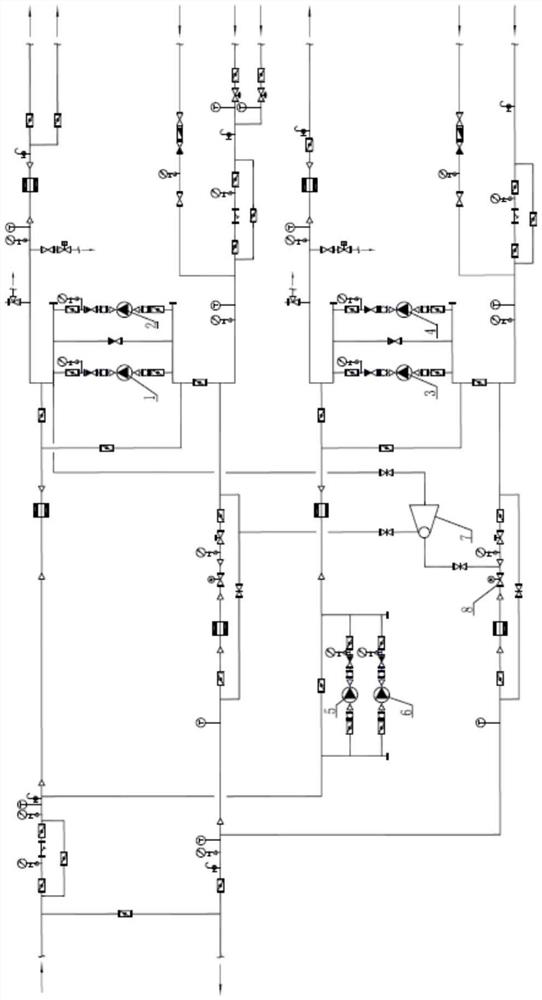

A heating unit and water mixing technology, which is applied in heating systems, household heating, space heating and ventilation, etc., can solve the problems of throttling loss, increase the power consumption of heating units, and reduce the motor. Power, guaranteed heating effect, stable constant pressure value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

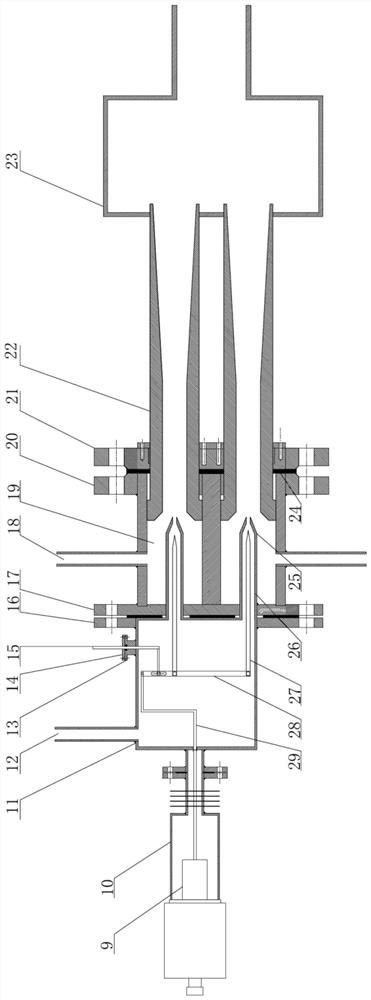

Embodiment 1

[0034] In this embodiment, the temperature of the primary network water supply before mixing is set to 85°C, the return water temperature of the primary grid is set to 45°C, the primary network water supply pressure is about 0.60MPa, and the unit heat consumption is calculated according to the heat demand of the user. In this embodiment, Set the heating unit consumption to 40W / ㎡. After mixing, the water supply temperature of the secondary network is set to 55°C, and the return water temperature is set to 45°C. The hourly flow rate can be calculated based on the heat supply. After mixing, the constant pressure value of the return water of the secondary network in the low area is set to 0.40MPa, and the working pressure is ≤0.55MPa; the constant pressure value of the return water of the secondary network in the high area after mixing is set to 1.00MPa, and the design working pressure is less than or equal to 1.15MPa . The circulating pump draws a part of the secondary network r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com