Novel high-robustness high-lift-drag-ratio laminar flow airfoil profile of wind turbine

A technology with high robustness and high lift-to-drag ratio, which is applied to wind turbines that are consistent with the wind direction, wind turbines that are at right angles to the wind direction, and wind turbines to achieve high robustness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as a limitation of the present invention.

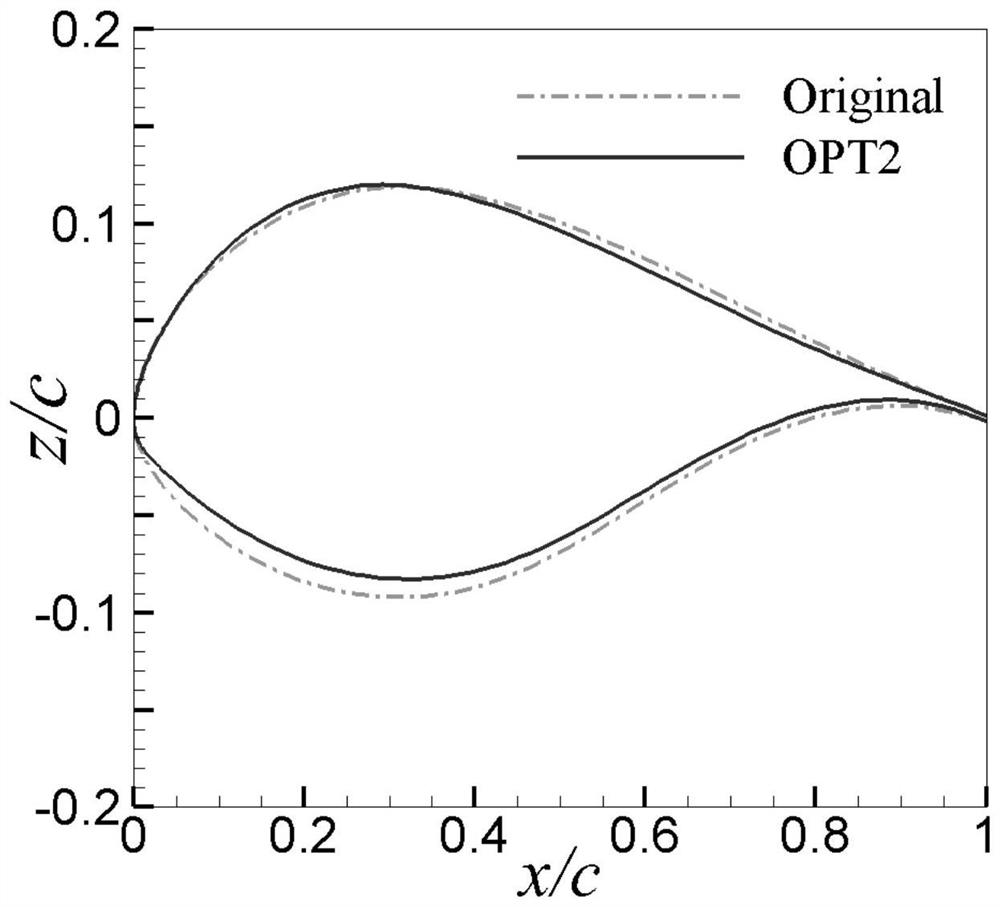

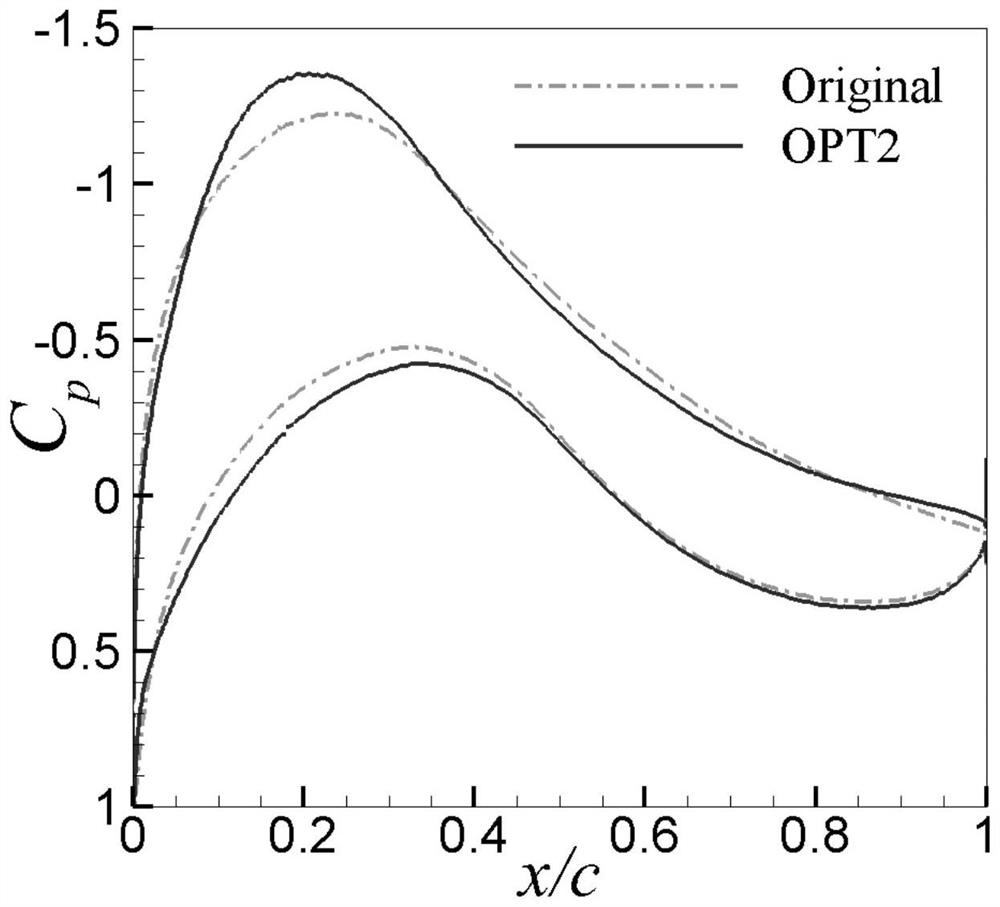

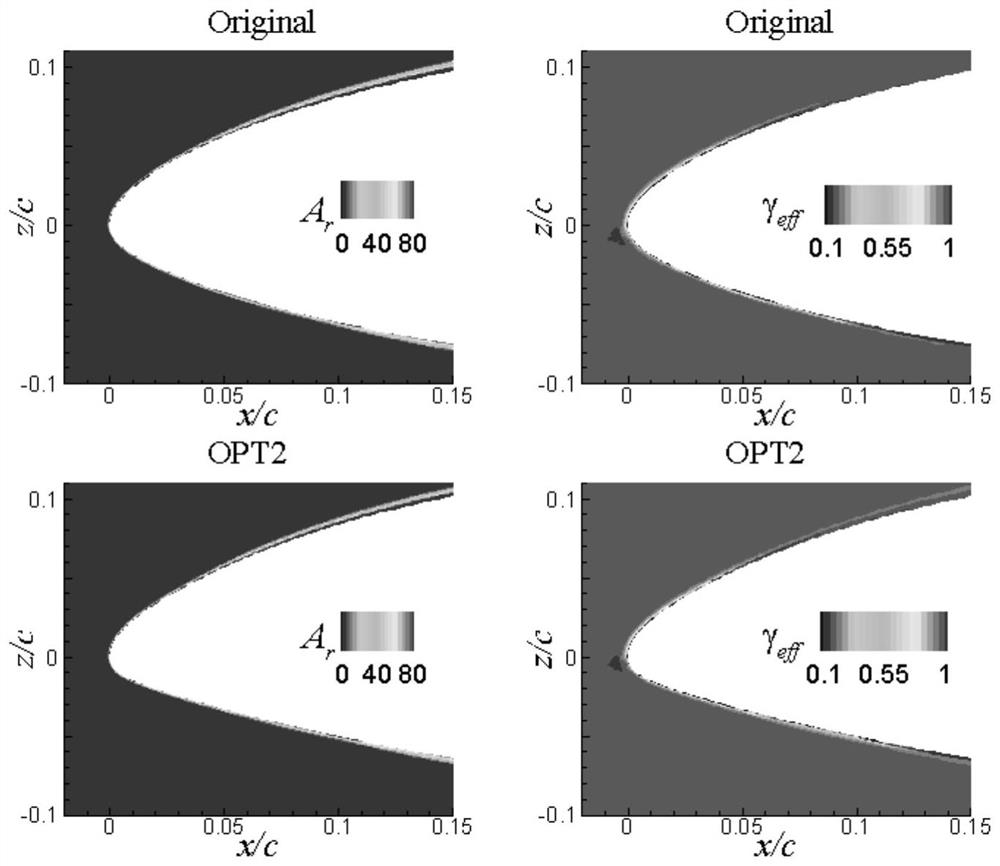

[0052] This embodiment proposes a highly robust and high lift-to-drag ratio wind turbine laminar airfoil suitable for complex operating environments considering the influence of rough elements, and has excellent high lift-to-drag ratio on both smooth and rough surfaces.

[0053] The high-precision transition prediction model considering the influence of rough elements is used to predict the transition characteristics and aerodynamic characteristics of the airfoil under rough conditions. Flow optimization design, and finally obtain a new laminar airfoil with high lift-to-drag ratio on both smooth and rough surfaces. The indicator requirements are:

[0054] 1. Working state: Ma=0.1, Re=1.8E6, AoA=2°, Tu=0.15%

[0055] 2. Design objective: lift-drag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com