Reinforced concrete silo top plate formwork construction method

A technology of reinforced concrete and construction methods, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, preparation of building components on site, etc., which can solve the problems of large construction operations and increased construction costs cost, manpower, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make those skilled in the art better understand the present invention, the present invention will be further clearly and completely described below with reference to the accompanying drawings and the embodiments. It should be noted that, in the case of no conflict, the features in the implementation manners and the examples in the present application may be combined with each other.

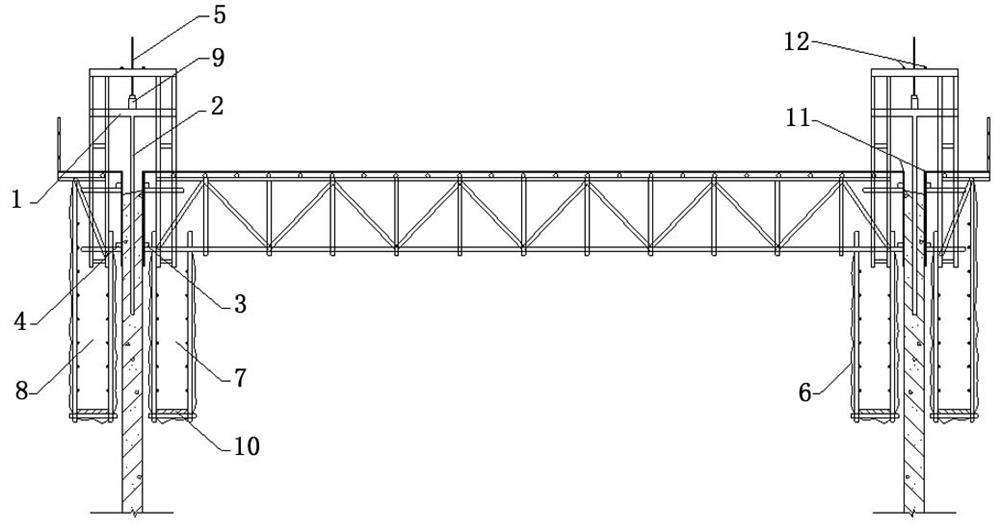

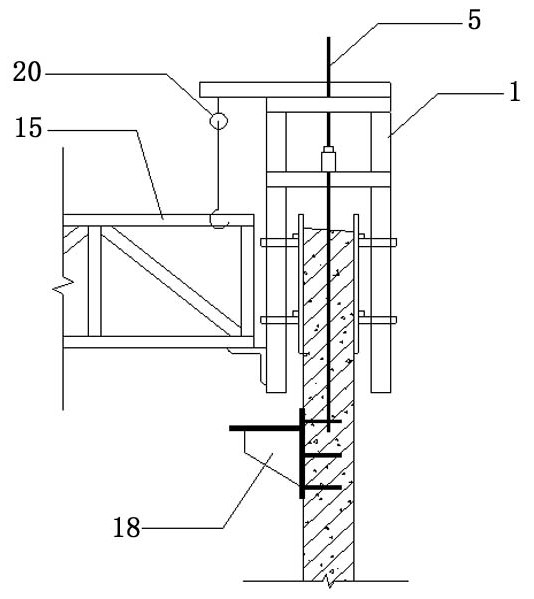

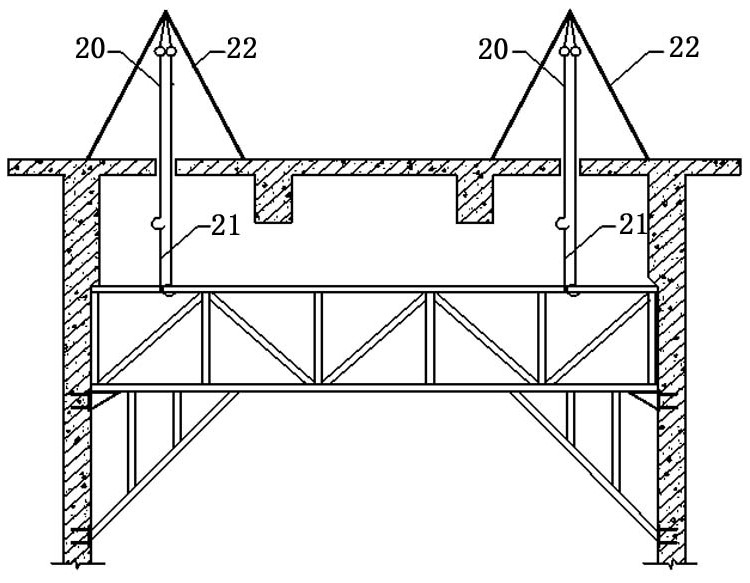

[0027] A typical embodiment of the present invention provides a reinforced concrete silo roof formwork construction method. After the silo wall sliding form construction is completed, the sliding form platform is lowered to a predetermined elevation for the first time and then reinforced to serve as the silo roof. The roof formwork for construction supports the platform; after the construction of the silo roof is completed, the sliding form platform is lowered to the ground for the second time and the sliding form platform is dismantled as a whole.

[0028] The sliding form pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com