Corrugated steel plate and concrete combined web plate for square steel tube suspension bridge cable bent tower

A steel plate concrete and combined web technology, which is applied to suspension bridges, bridges, bridge materials, etc., can solve the problems such as the inability to give full play to the energy consumption characteristics of materials, weak vertical load bearing capacity, and easy brittle damage, so as to reduce the vertical formwork process. , the effect of high bearing capacity and slow degradation of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

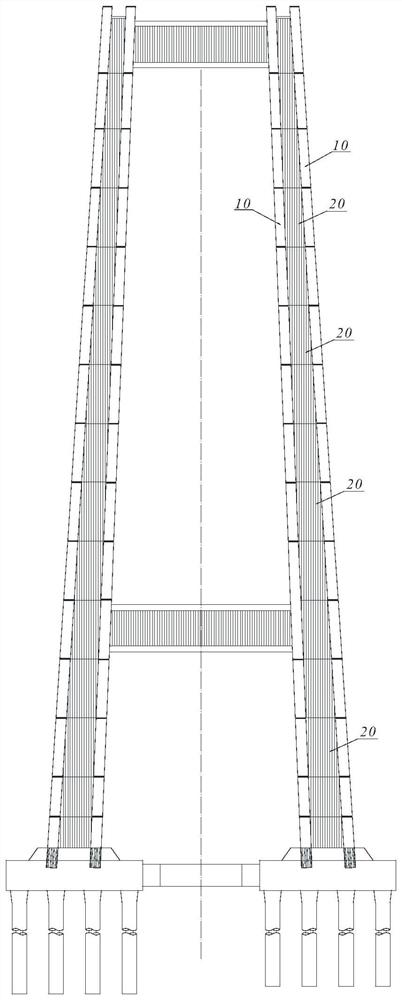

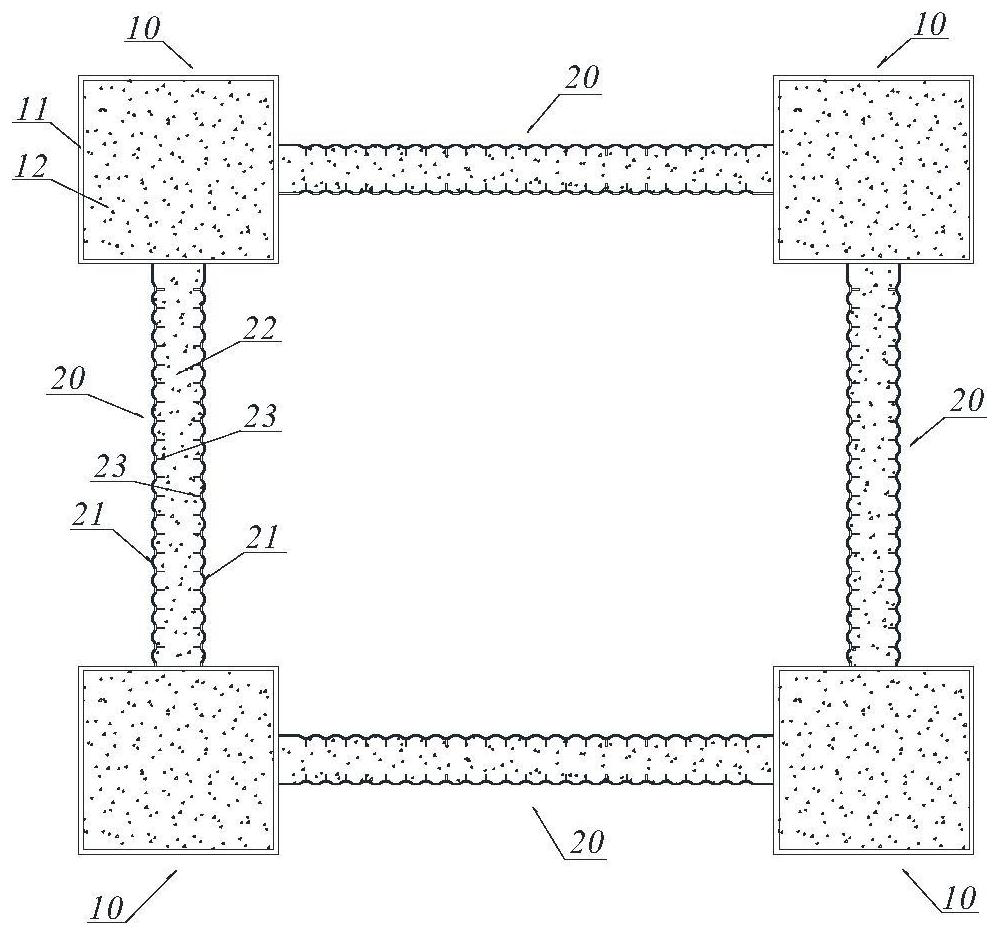

[0021] refer to figure 1 and figure 2 , the present invention is a corrugated steel plate concrete composite web for a square steel tube suspension bridge tower. The suspension bridge tower column includes a square steel tube concrete column 10 and a web 20, and the web is passed between the adjacent two square steel tube concrete columns 10. 20 are connected to form a box frame structure. The web 20 is composed of corrugated steel plates 21 , web concrete 22 and half-open shear connectors 23 . A pair of the corrugated steel plates 21 are arranged at intervals along the thickness direction of the web 20 . The crest and valley portions of the corrugated steel plates 21 extend along the width direction of the web 20 . Outer wall welding. The half-open shear connectors 23 are arranged at equal intervals along the height direction of the web 20 , and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com