Novel continuous spinning viscose filament yarn treating agent as well as preparation method and application thereof

A treatment agent and spunbond technology, which is applied in the field of new continuous spunbond filament treatment agent and treatment, can solve the problems of inability to meet the production needs of various products, low CMC film forming strength, poor degradability, etc., and achieve excellent solubility Water-based, waste degradable, good cohesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

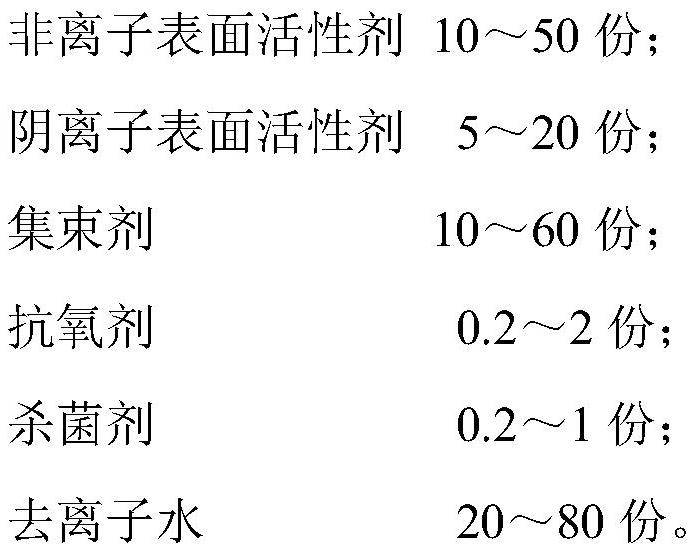

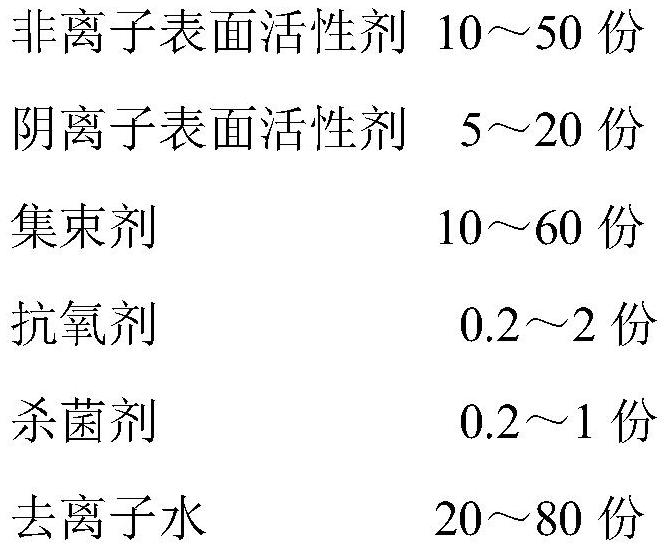

[0019] A new type of continuous spun viscose filament treatment agent is composed of the following parts by mass:

[0020]

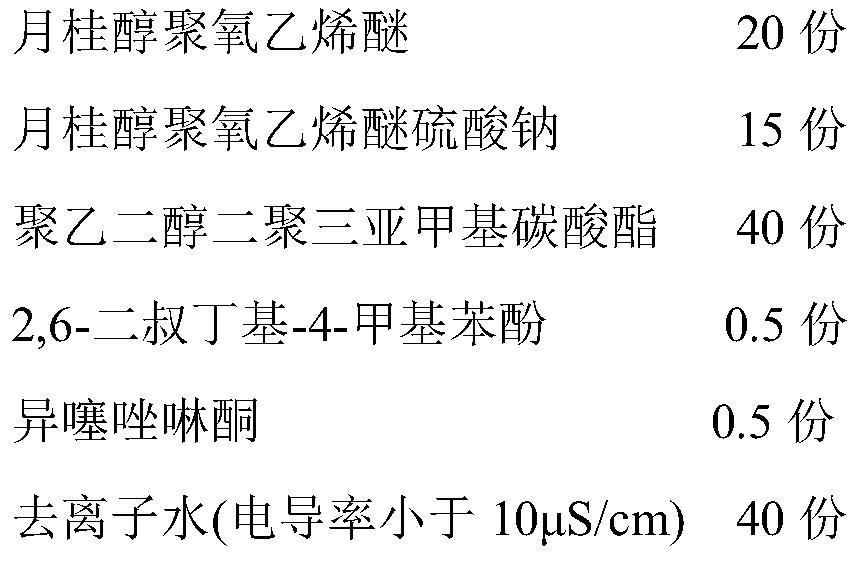

[0021] The preparation method is as follows: raising the temperature of laureth to 50° C., adding 2,6-di-tert-butyl-4-methylphenol and deionized water, stirring for 10 min, and then adding sodium laureth sulfate in turn , polyethylene glycol dimerized trimethylene carbonate and isothiazolinone, and stirred for 30 min to obtain a continuous spun viscose filament treatment agent:

Embodiment 2

[0023] A new type of continuous spun viscose filament treatment agent, the proportion by weight is as follows:

[0024]

[0025] The preparation method is as follows: the lauryl alcohol polyoxyethylene polyoxypropylene ether is heated to 50° C., tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol ester and deionized water are added, Stir for 10 min, then add sodium lauryl ether sulfate, methoxy polyethylene glycol polytrimethylene carbonate and isothiazolinone in sequence, stir for 30 min to obtain a continuous spun viscose filament treatment agent.

Embodiment 3

[0027] A new type of continuous spun viscose filament treatment agent, the proportion by weight is as follows:

[0028]

[0029] The preparation method is as follows: the cetearyl alcohol polyoxyethylene ether is heated to 70° C., 2,6-di-tert-butyl-4-methylphenol and deionized water are added, stirred for 10 minutes, and then lauryl alcohol polyoxyethylene is added in sequence Sodium ether phosphate, sodium lauryl polyoxyethylene ether sulfate, carboxyl-terminated trimethylene carbonate and glutaraldehyde, and stirring for 30 minutes to obtain a continuous spun viscose filament treatment agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com