Van der Waals heterojunction WS2/h-BN and self-assembly preparation method thereof

A heterojunction, h-bn technology, applied in lubricating compositions and other directions, can solve problems such as difficulty in improving lubricating performance, loss of lubricating performance, inability to meet the needs of high-performance solid lubricants, etc., and achieves simple preparation process and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

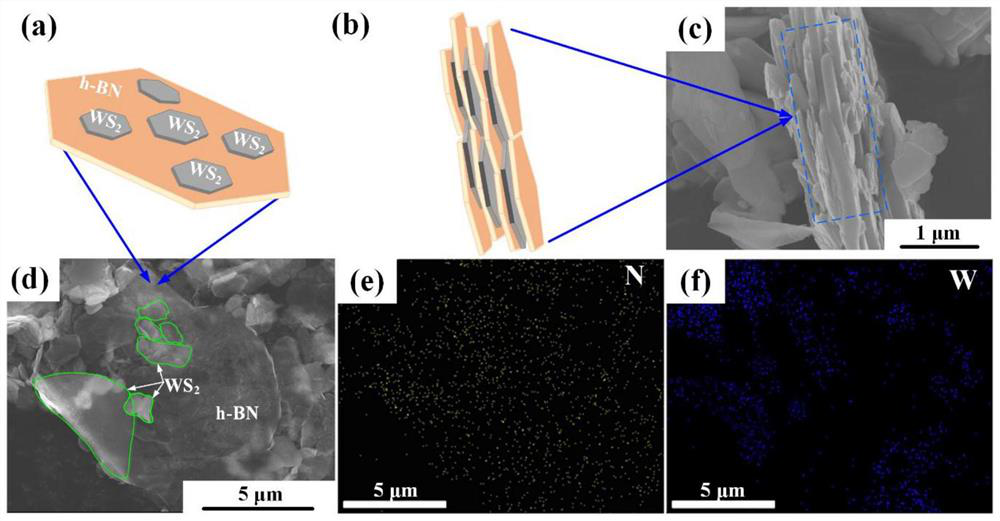

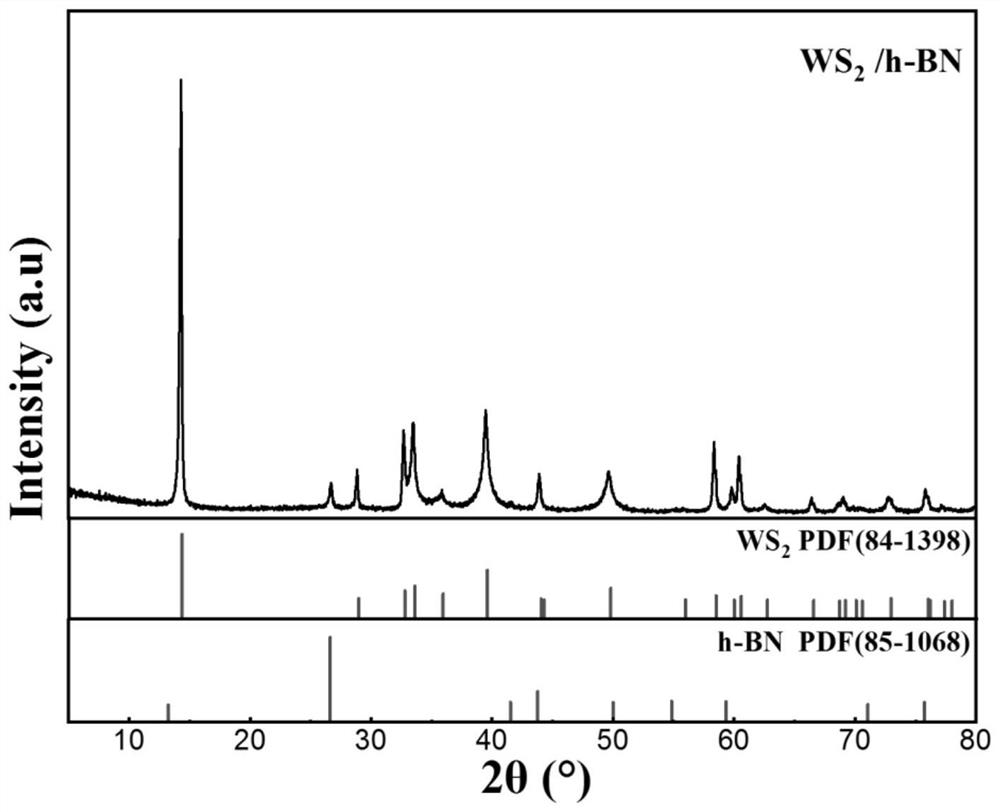

[0034] van der Waals heterojunction WS 2 Self-assembly preparation of / h-BN:

[0035] (1) Weigh 0.25g of hexagonal boron nitride and disperse it into 200ml of deionized water, weigh 0.75g of tungsten disulfide and disperse it into 600ml of deionized water, and disperse by ultrasonic vibration for 1.0h respectively;

[0036] (2) 0.26g of cationic modifier 2-methylpropanoyloxyethyltrimethylammonium chloride DMC (75wt%) was added dropwise to the hexagonal boron nitride dispersion, and 0.4g of anion was added to the tungsten disulfide dispersion Modifier butyl xanthate;

[0037] (3) stirring the dispersion liquid after adding the modifier on a magnetic stirrer for 3h;

[0038] (4) After stirring, transfer the dispersion of hexagonal boron nitride into a clean beaker, and then drop the tungsten disulfide dispersion into the dispersion of hexagonal boron nitride with a dropper;

[0039] (5) magnetically stir the mixed liquid of hexagonal boron nitride and tungsten disulfide for 4...

Embodiment 2

[0046] van der Waals heterojunction WS 2 Self-assembly preparation of / h-BN:

[0047](1) Weigh 0.25g of hexagonal boron nitride and disperse it into 250ml of deionized water, weigh 0.75g of tungsten disulfide and disperse it into 750ml of deionized water, and disperse by ultrasonic vibration for 1.0h respectively;

[0048] (2) Add 0.35g of cationic modifier polydiallyldimethylammonium chloride PDDA (35wt%) to the hexagonal boron nitride dispersion, and add 0.375g of anionic modifier butyl to the tungsten disulfide dispersion Base xanthate ROCSSNa;

[0049] (3) stirring the dispersion liquid after adding the modifier on a magnetic stirrer for 3h;

[0050] (4) After stirring, transfer the dispersion of hexagonal boron nitride into a clean beaker, and then drop the tungsten disulfide dispersion into the dispersion of hexagonal boron nitride with a dropper;

[0051] (5) magnetically stir the mixed liquid of hexagonal boron nitride and tungsten disulfide for 45min, then let stan...

Embodiment 3

[0055] van der Waals heterojunction WS 2 Self-assembly preparation of / h-BN:

[0056] (1) Weigh 0.25g of hexagonal boron nitride and disperse it into 500ml of deionized water, weigh 0.25g of tungsten disulfide and disperse into 500ml of deionized water, and disperse by ultrasonic vibration for 1.0h respectively;

[0057] (2) 0.57g of cationic modifier polydiallyldimethylammonium chloride PDDA (35wt%) was added dropwise to the hexagonal boron nitride dispersion, and 0.4g of anionic modifier was added to the tungsten disulfide dispersion. Sodium dialkylbenzene sulfonate LAS;

[0058] (3) stirring the dispersion liquid after adding the modifier on a magnetic stirrer for 3h;

[0059] (4) After stirring, transfer the dispersion of hexagonal boron nitride into a clean beaker, and then drop the tungsten disulfide dispersion into the dispersion of hexagonal boron nitride with a dropper;

[0060] (5) magnetically stir the mixed liquid of hexagonal boron nitride and tungsten disulfid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com