Civil building construction material conveying system

A technology for conveying systems and civil engineering, applied in transportation and packaging, load hanging components, traveling mechanisms, etc., can solve the problems of high risk factor in hoisting heavy components, low lifting efficiency, easy to damage the paint surface of components, etc., to achieve high practicality Value and promotion value, improve the overall stability, and avoid the effect of loosening and falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are only used to more clearly illustrate the technical solutions of the present invention, and are therefore only used as examples, and cannot be used to limit the protection scope of the present invention.

[0023] It should be noted that, unless otherwise specified, the technical or scientific terms used in this application should have the usual meanings understood by those skilled in the art to which the present invention belongs.

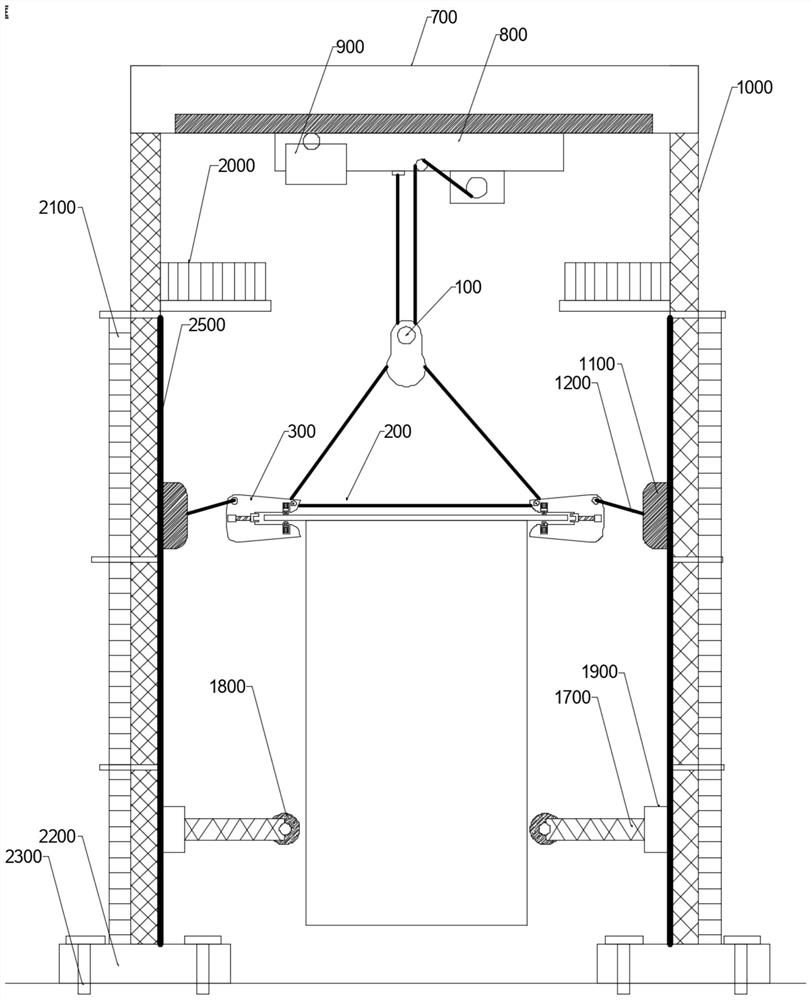

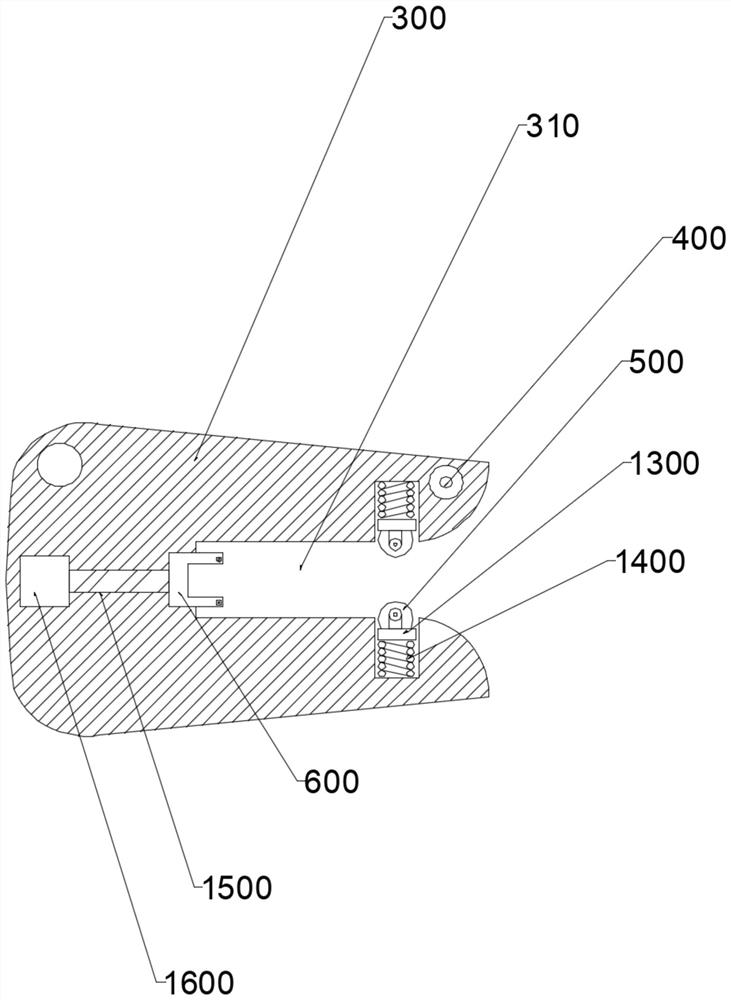

[0024] like figure 1 and figure 2 As shown, a specific embodiment of the present invention provides a civil construction material conveying system, including a hoisting assembly and a transfer assembly; the hoisting assembly includes a hook 100 and a sling 200, and there are oppositely arranged below the hook 100 The hoisting block 300 is provided with hoisting pulleys 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com