Engine valve driving device

A technology of engine valves and driving devices, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of engine height increase, etc., and achieve the effects of reducing clearance, shortening reaction time, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

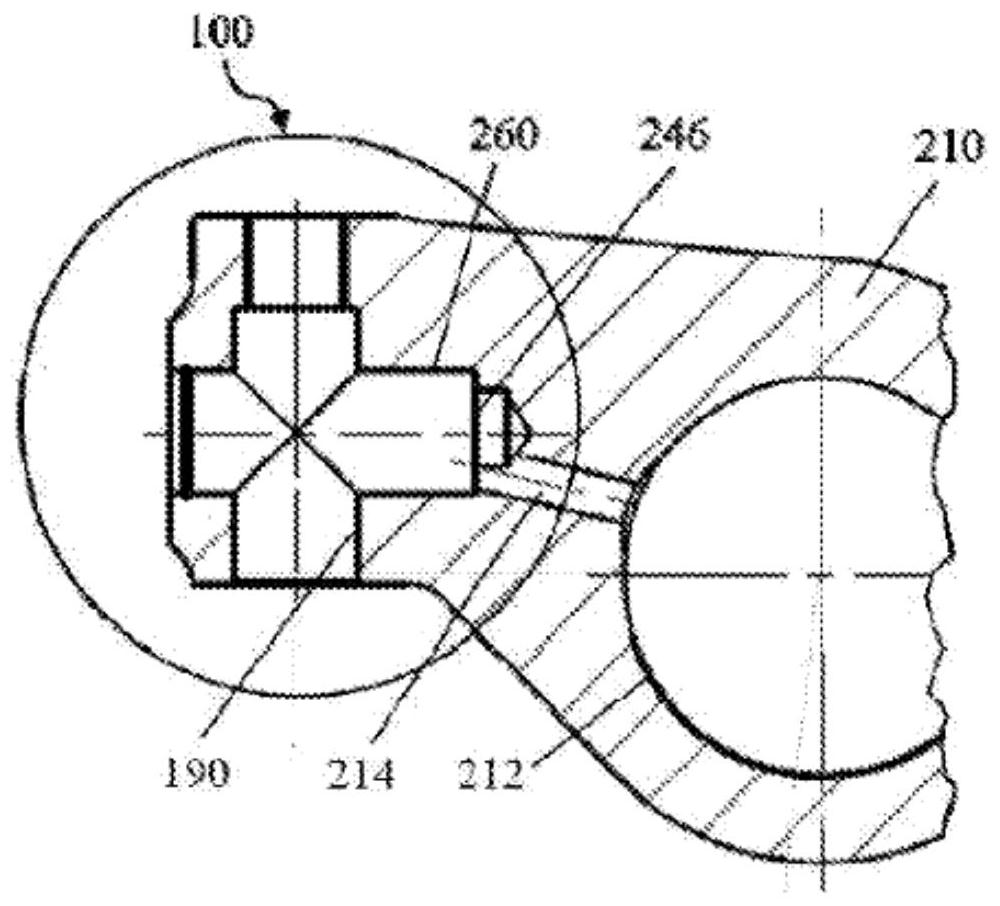

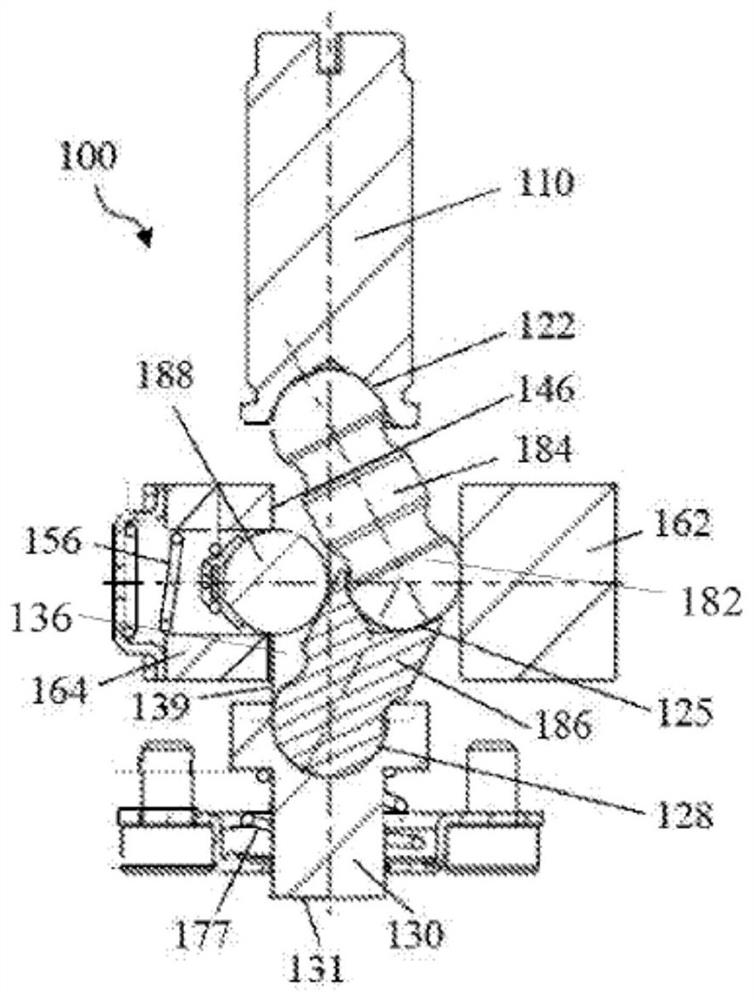

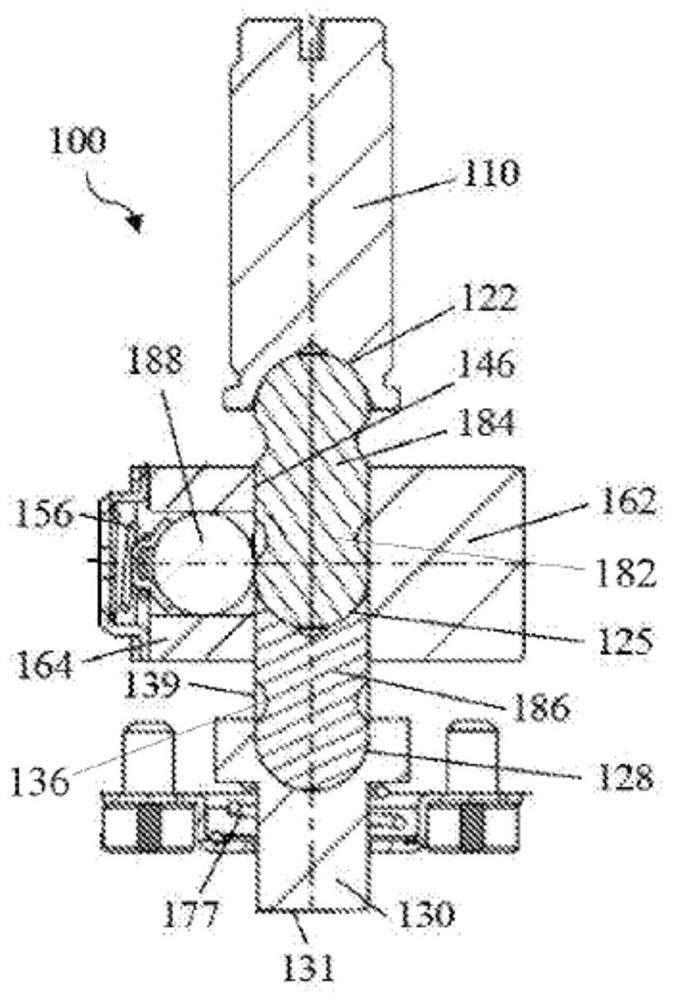

[0116] According to an embodiment of the present invention, as figure 1 , 2 As shown in FIG. and 3 , the engine valve drive 100 may include a housing 210 , a start piston 162 , a drive piston 130 , a linkage mechanism 182 , and one or more of a guide mechanism 137 , an anti-rotation mechanism 138 , and a positioning mechanism 150 .

[0117] The case 210 may be the rocker arm or valve bridge of the engine. In this embodiment, the box body 210 is a rocker arm, which can be similar to the rocker arm (210b) of EP2384396. like figure 1 As shown, the rocker arm is mounted on a rocker arm shaft (not shown) through hole 212 .

[0118] like figure 1 As shown, the housing 210 includes an actuation piston bore 260 and a drive piston bore 190 . Preferably, the actuation piston bore 260 and the drive piston bore 190 intersect each other perpendicularly. The activation piston 162 is slidably disposed in the activation piston bore 260 . The drive piston 130 is disposed in the drive pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com