Impeller assembly for axial flow compressed air pressurization in shaft seal cavity and dry gas seal structure

A dry gas seal and shaft seal technology, which is applied to parts of pumping devices for elastic fluids, engine seals, pump components, etc., can solve the problems of complicated numerical calculation and comparison process and long time for new contour search, etc. Achieve the effects of strong opening ability, high operation stability and improved gas film stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

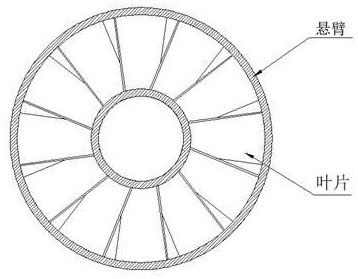

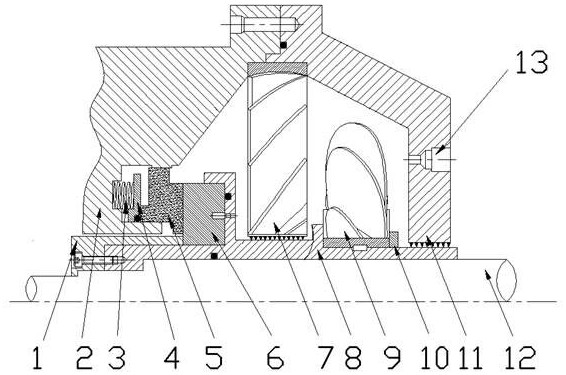

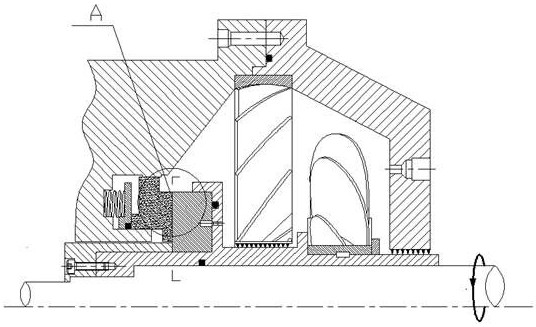

[0054] The impeller assembly for the axial flow pressurization in the shaft seal cavity includes a stationary impeller 7 and a guide impeller 9. The guide impeller 9 and the static impeller 7 are sequentially arranged along the flow direction of the sealing medium in the shaft seal cavity, and the guide impeller 9, the static impeller There is a gap between the impellers 7, the guide impeller 9 rotates with the shaft 12, the outer edge of the stationary impeller 7 is fixed on the inner wall of the shaft seal cavity, the shaft 12 passes through the central mounting hole of the stationary impeller 7, and the central mounting hole of the stationary impeller 7 is provided with Spiral seal, the vane direction of the stationary impeller 7 is opposite to the vane direction of the guide impeller 9 .

Embodiment 2

[0056] On the basis of Embodiment 1, the outer edge of the stationary impeller 7 is provided with a cantilever, and the outer edge of the stationary impeller 7 is fixed on the inner wall of the shaft seal cavity through the cantilever.

Embodiment 3

[0058] Except that the number of blades of the guide impeller 9 is 8 and the number of blades of the stationary impeller 7 is 15, the rest is the same as that of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com