Environment-friendly full-automatic multifunctional indoor spraying robot

A multi-functional room, fully automatic technology, applied in the direction of coating, manipulators, spray booths, etc., can solve the problems of large movable space, large turning range, and reduced work efficiency, so as to speed up the air-drying process, improve efficiency, and shorten the interval the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

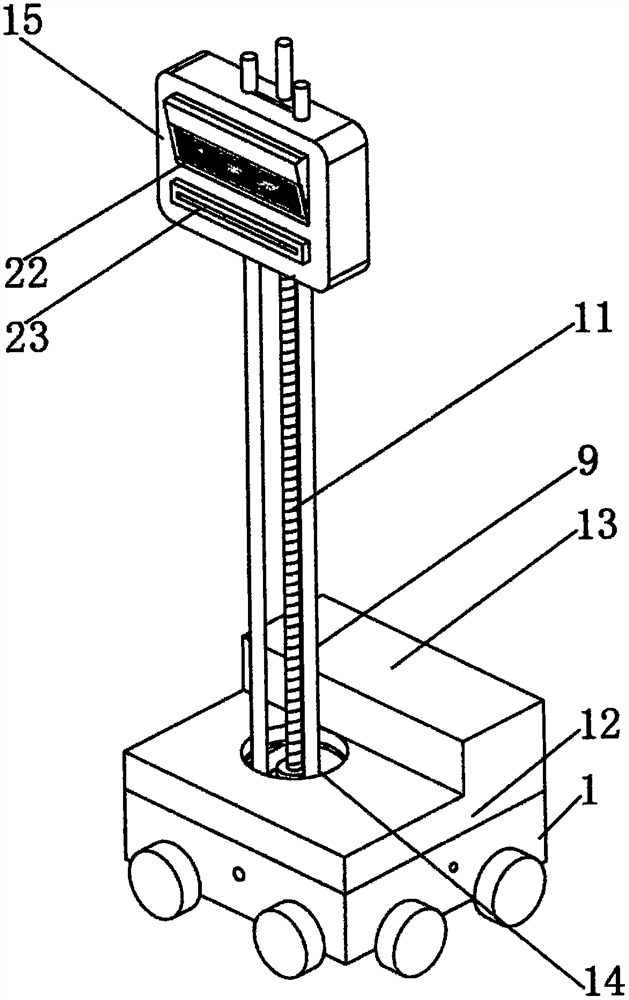

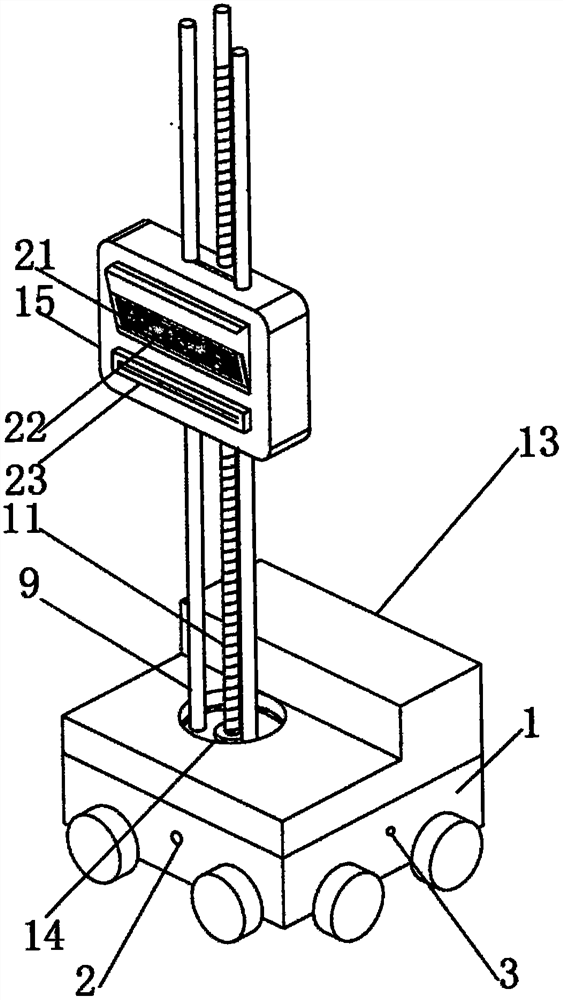

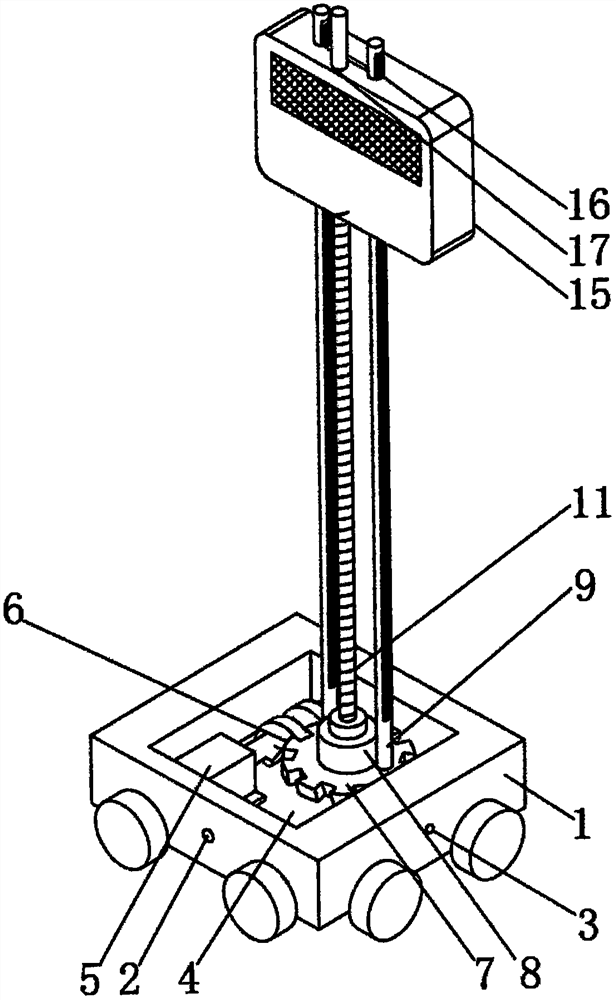

[0027] like Figure 1-Figure 5 As shown, an environmentally friendly fully automatic multifunctional indoor spraying robot includes an AVG trolley 1 and a spraying rack 15. The upper end of the AVG trolley 1 is provided with two sets of limit bolts 9 side by side, and a wire is arranged between the two sets of limit bolts 9. The rod 11 and the spraying rack 15 are movably installed on two sets of limit bolts 9. The AVG trolley 1 is provided with a steering mechanism, which is used to control the rotation of the spraying rack 15. Two sets of inclined settings are installed inside the spraying rack 15. The fan blade 18, the side of the fan blade 18 is provided with a heating rod 21, the side of the lower end of the spraying frame 15 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com