Ocean pile foundation corrosion protection device and using method thereof

A corrosion protection and pile foundation technology, which is applied in protection devices, infrastructure engineering, construction, etc., can solve problems such as corrosion in the splash zone, and achieve the effects of prolonging service life, improving anti-corrosion performance, and simple disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

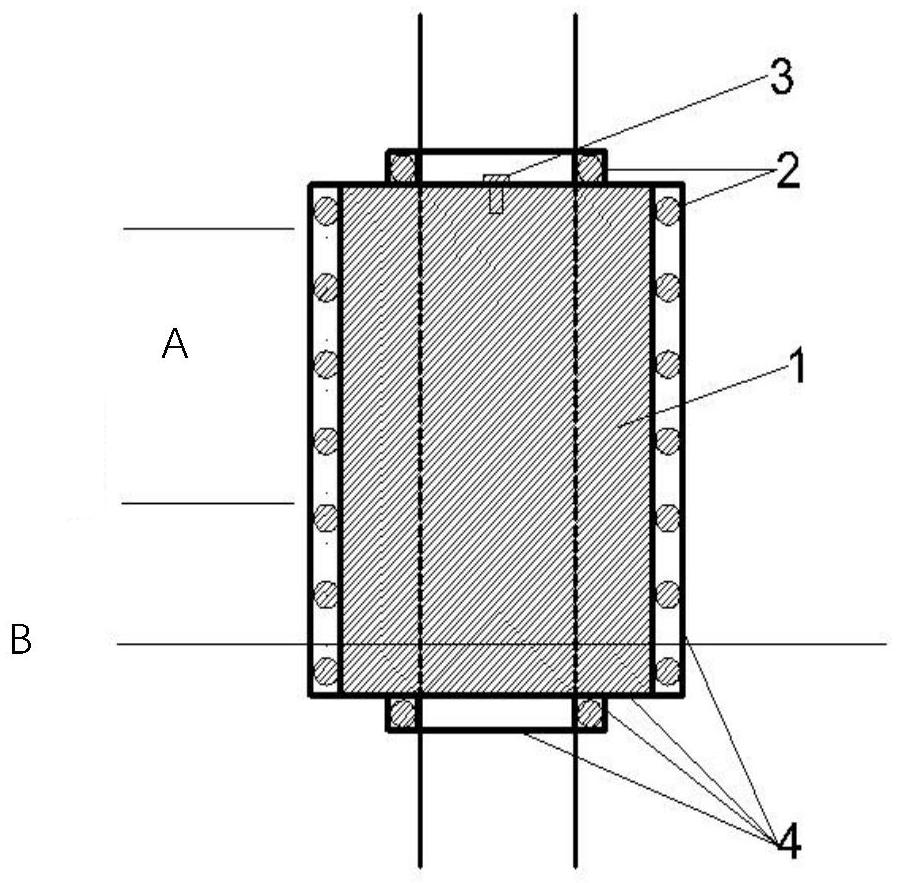

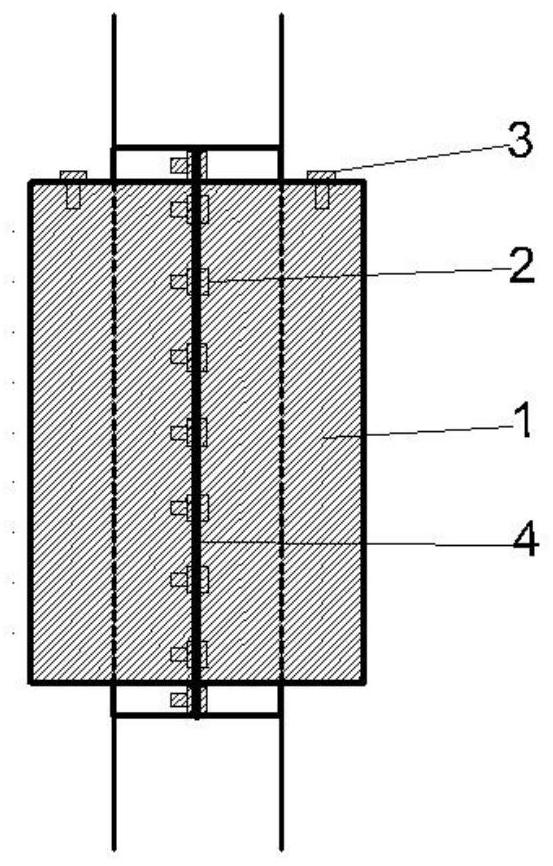

[0032] like figure 1 and 2 As shown, a marine pile foundation corrosion protection device includes a split cylinder 1, a fixing bolt 2, a through-hole fixing bolt 3, a low-volatile oil and a rubber sealing strip 4.

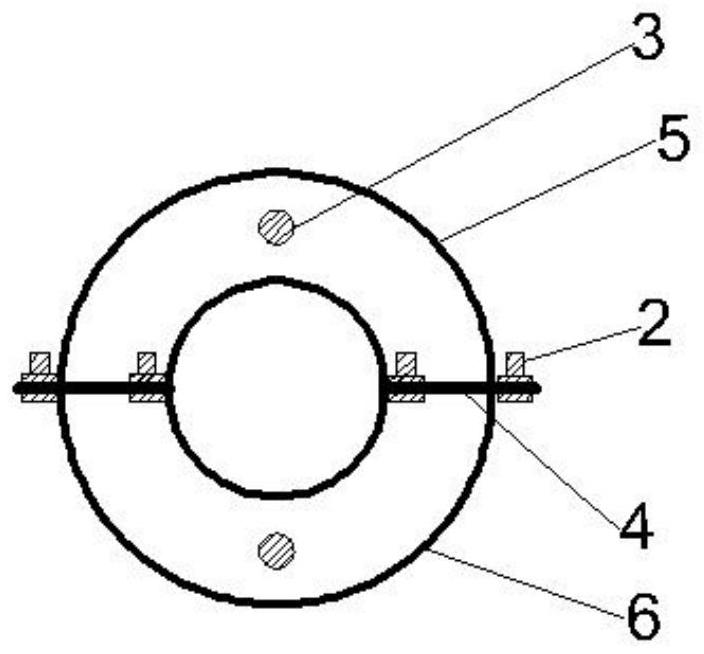

[0033] see image 3 , the split cylinder 1 includes a first split mold 5 and a second split mold 6 that are axially symmetric, and the first split mold 5 and the second split mold 6 are both close to the marine pile foundation at both ends Contact and a vertical convex structure with a hollow cavity in the middle, the upper ends of the first split mold 5 and the second split mold 6 are installed with through-hole fixing bolts 3 for filling with low-volatile oil; The pair of split molds 5 and the second split mold 6 can be tightly compacted, and the split cylinder 1 is formed by clamping the first split mold 5 and the second split mold 6 through the fixing bolts 2 to form a seal. The cavity in the middle of the split cylinder 1 is filled with low volatility oil;...

Embodiment 2

[0035] This embodiment discloses a method for using the marine pile foundation corrosion protection device described in Embodiment 1, comprising the following steps:

[0036] 1) According to the actual situation of the sea area, determine the location of the five marine corrosion areas of the atmospheric area, the splash area, the tidal range area, the total immersion area and the sea mud area.

[0037] 2) According to the scope of the splash zone and the tidal range zone, select the first split mold 5 and the second split mold 6 with the dimensions of the upper and lower ends that fit the marine pile foundation, so that the split mold covers the entire splash zone area, And the bottom of the split mold is 0.5m below the sea level.

[0038] 3) Fix the first split mold 5 and the second split mold 6 in the splash zone and the tidal zone, and use the fixing bolts 2 to fix the first split mold 5 and the second split mold 6 together.

[0039] 4) The gap between the first split mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com