Circulating agriculture and animal husbandry waste pretreatment system

A waste and pretreatment technology, applied in bio-organic part treatment, agriculture, chemical fertilizer treatment heating/cooling, etc., can solve the problems of chicken manure stacking that cannot meet the harmless requirements, waste of heat in the head space, and lower than the hygienic index 50 degrees Celsius standard and other issues to achieve the effect of avoiding heat waste, increasing utilization rate, and realizing heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

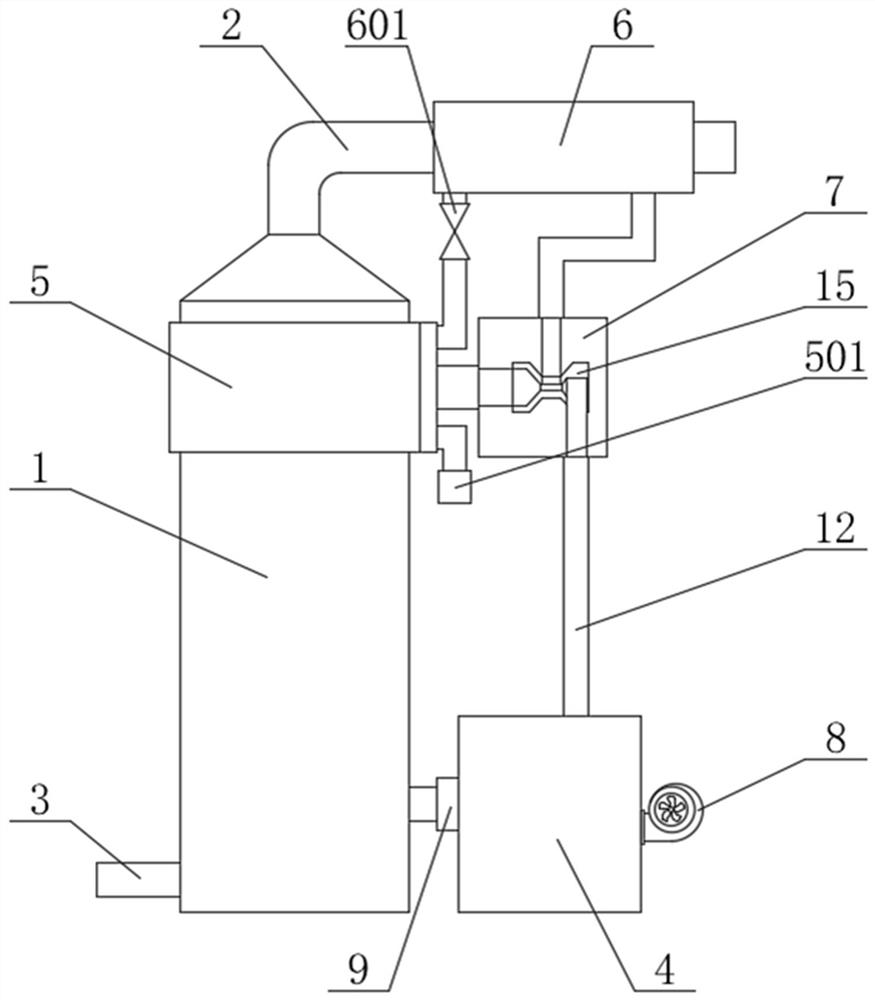

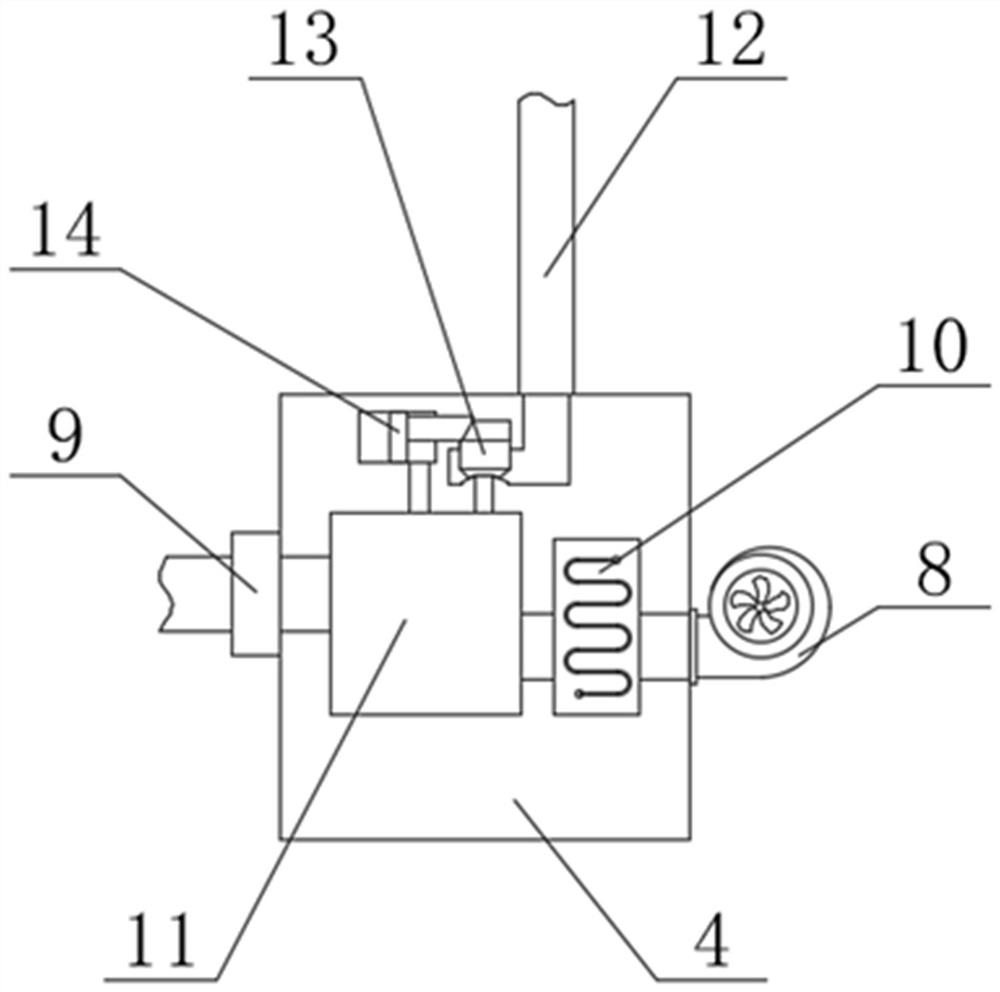

[0027] see Figure 1-2, the present invention provides a recycling agricultural and animal husbandry waste pretreatment system, which includes a static compost bin body 1, a bottom heating module 4, and a top thermal insulation module 5. The top of the static compost bin body 1 is provided with a bin body outlet pipe 2 , the silo body outlet pipe 2 is used to discharge the moisture and odor in the static composting silo body 1, the outer side of the silo body outlet pipe 2 is provided with a heat recovery module 6, and the heat recovery module 6 is provided with a compressor and a heat exchanger, The compressor compresses the air in the heat recovery module 6, and the heat exchange is realized between the heat exchanger and the air outlet pipe 2 of the silo. The left side of the bottom heating module 4 is provided with a restrictor valve 9, which is connected to the static state. The compost bin body 1 is connected, and the restrictor valve 9 prevents excessive air intake. The...

Embodiment 2

[0035] In this embodiment, the same parts as those in Embodiment 1 will not be repeated, and the difference lies in the work flow of a recycling agricultural and animal husbandry waste pretreatment system.

[0036] Workflow: When the air flow rate entering the bottom heating module 4 cannot be more than that sent into the static compost bin body 1 from the restrictor valve 9, the pressure in the heating air tank 11 is always the same as the atmospheric pressure. The air in the heated air tank 11 cannot lift the air distribution plug 13, and under the elastic force of the elastic force reset assembly around the pressure limit assembly 14, the pressure limit assembly 14 is driven to reset, and the air distribution plug 13 is reset. Limit, so that the air in the heating air tank 11 no longer enters the voltage stabilization module 7 along the air distribution pipe 12, and the air self-circulation is realized between the top insulation module 5 and the heat recovery module 6.

Embodiment 3

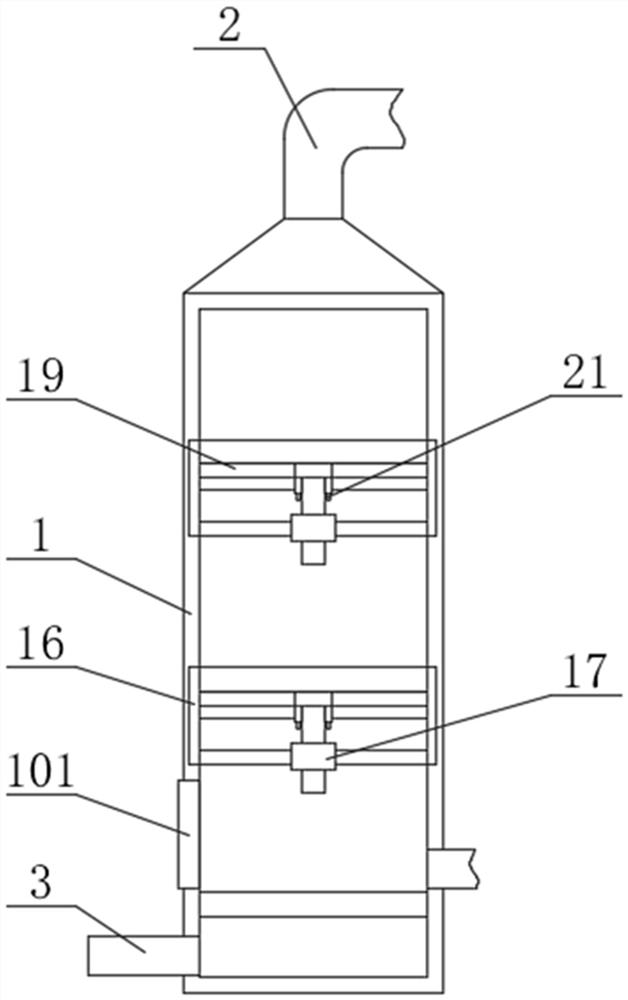

[0038] see Figure 2-6 , the present invention provides a recycling agricultural and animal husbandry waste pretreatment system, which includes a static compost bin body 1 and a bin module, the inner side of the static compost bin body 1 is provided with a bin module, and the bin module includes a bin silo assembly 16. Lifting drive device 17 and sub-silo fan blade 19. Lifting and driving device 17 is fixed on the inner side of the sub-silo assembly 16 through a connecting shaft. The top of the lifting and driving device 17 is provided with a fan blade shaft 18, and the lifting and driving device 17 drives the fan blade The shaft 18 is lifted up and down, and the fan blades 19 of the sub-silo are arranged around the fan blade shaft 18. The fan blade shaft 18 drives the sub-silo fan blades 19 to rotate. The torsion spring drives the adjacent fan blade shafts 18 to rotate relative to each other, and the sub-silo fan blades 19 are net-shaped fan blades of one-twelfth circle, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com