Steel machining positioning platform

A positioning platform, steel technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of unstable fixation, troublesome use, difficult to operate, etc., to improve the fixed positioning performance, improve stability, and increase friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

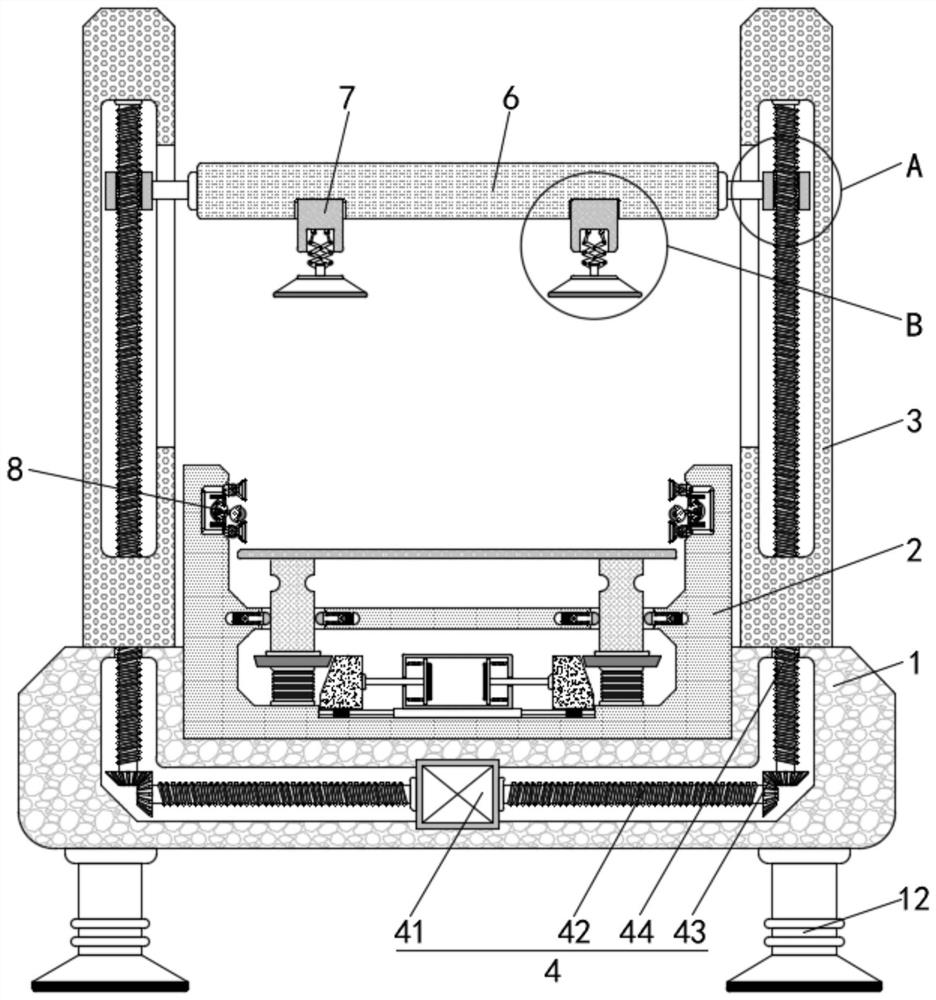

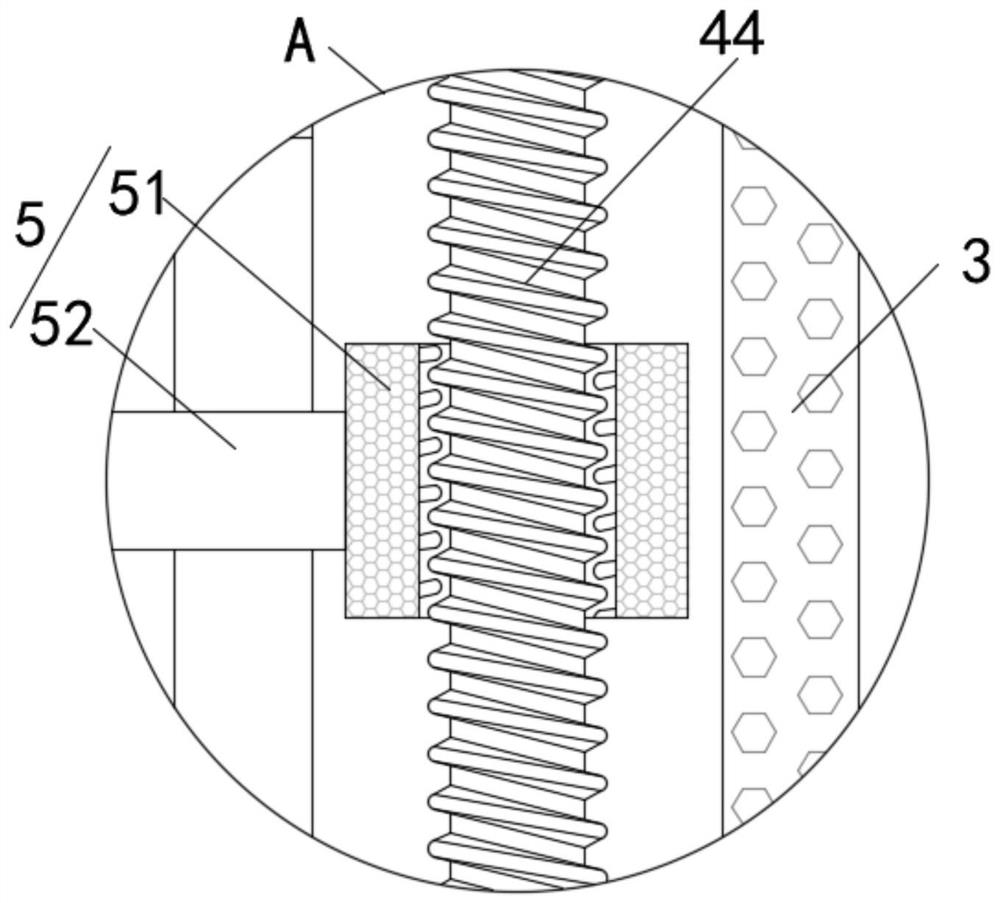

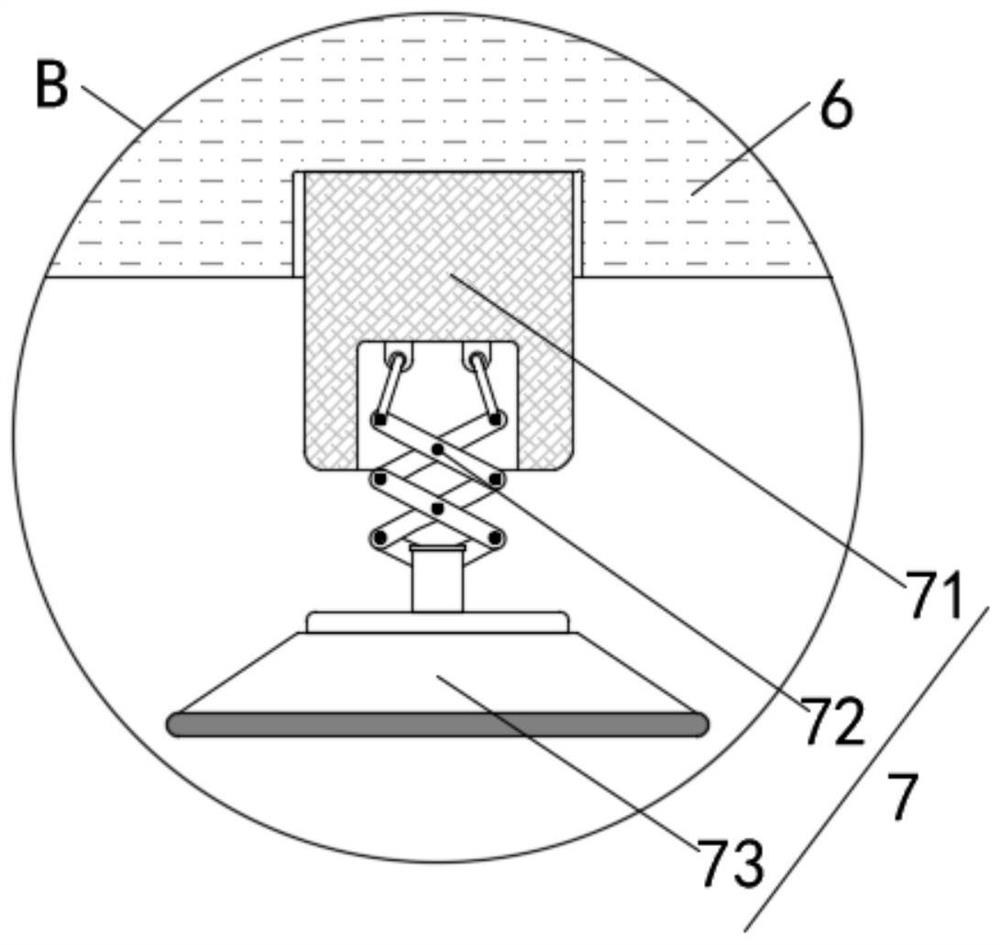

[0028] see figure 1 and image 3 and Figure 4 , a steel processing positioning platform, including a fixed base 1, the upper side of the fixed base 1 is fixedly embedded with a fixed base 2, and the upper surface of the fixed base 1 is located on the left and right sides of the fixed base 2 and is fixedly installed with mounting posts 3, And the interior of the fixed base 1 is provided with a drive assembly 4, and a movable assembly 5 is movably installed on the drive assembly 4, a positioning block 6 is fixedly connected between the movable assemblies 5, and a processing positioning assembly 7 is installed on the lower side of the positioning block 6. , and the processing positioning assembly 7 includes a positioning member 71 , a buffer link 72 is installed on the lower side of the positioning member 71 , and a processing positioning mechanism 73 is fixedly connected to the lower end of the buffer link 72 .

[0029] Further, the drive assembly 4 includes a drive mechanism...

Embodiment 2

[0036] see Figure 1 to Figure 5 , a steel processing positioning platform, including a fixed base 1, the upper side of the fixed base 1 is fixedly embedded with a fixed base 2, and the upper surface of the fixed base 1 is located on the left and right sides of the fixed base 2 and is fixedly installed with mounting posts 3, And the interior of the fixed base 1 is provided with a drive assembly 4, and a movable assembly 5 is movably installed on the drive assembly 4, a positioning block 6 is fixedly connected between the movable assemblies 5, and a processing positioning assembly 7 is installed on the lower side of the positioning block 6. , and the processing and positioning assembly 7 includes a positioning member 71 , a buffer link 72 is installed on the lower side of the positioning member 71 , and a processing positioning mechanism 73 is fixedly connected to the lower end of the buffer link 72 .

[0037] Further, the drive assembly 4 includes a drive mechanism 41 , the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com