Reverse modeling method and device for pipeline

A reverse modeling and pipeline technology, applied in the field of digital factories, can solve the problems of high labor cost, large proportion of manual participation, slowing down the project progress and labor expenditure, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

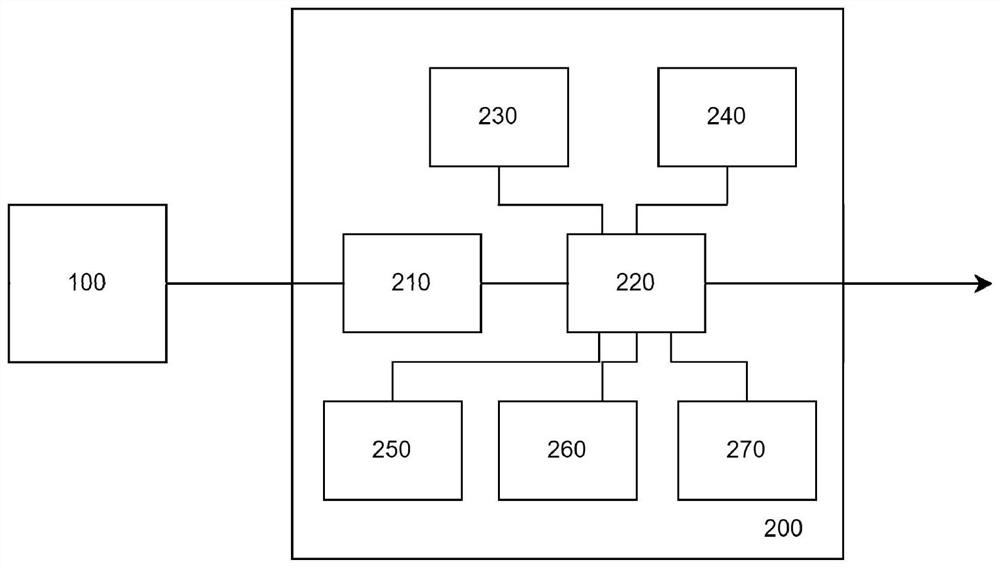

[0033] Attached below figure 1 Explain in detail.

[0034] The invention provides a pipeline reverse modeling device, which is used for reverse modeling of existing pipelines in an in-service factory and forming a complete twin model. Based on 3D laser scanning technology, this solution adopts abstract shape, intelligent judgment, and matching resource library (class library) to automatically identify and create object-oriented 3D models. At the same time, combined with intelligent P&ID, the three-dimensional pipeline is automatically logically sorted and divided, and the process attributes are given at the same time.

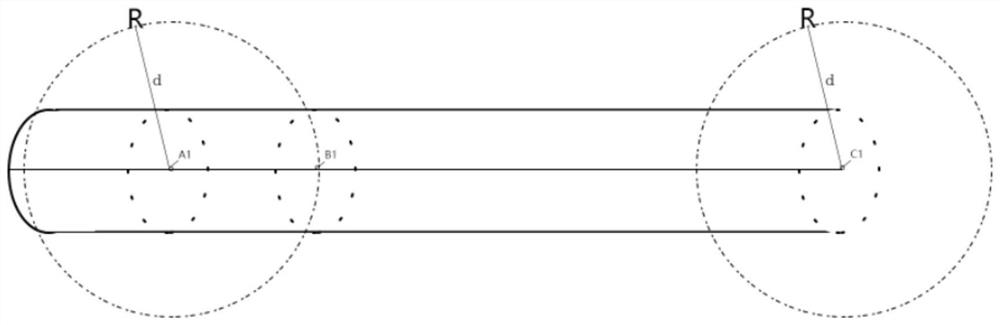

[0035] Specifically, the scheme is as follows. A scanning section 100 is provided, which acquires point cloud data about the pipeline at selected locations of the active plant using three-dimensional laser scanning. The selected location is the area selected by the scanner that needs to be inversely modeled, which is generally where all the pipes in the plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com