Power energy assembly, power energy assembly assembling method and vehicle

A technology for power energy and assembly assembly, applied in electric vehicles, vehicle components, vehicle energy storage, etc., can solve problems such as hydrogen leakage, lack of protective measures for hydrogen storage tanks, and increase the complexity of vehicle assembly operations, so as to improve the collision rate. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

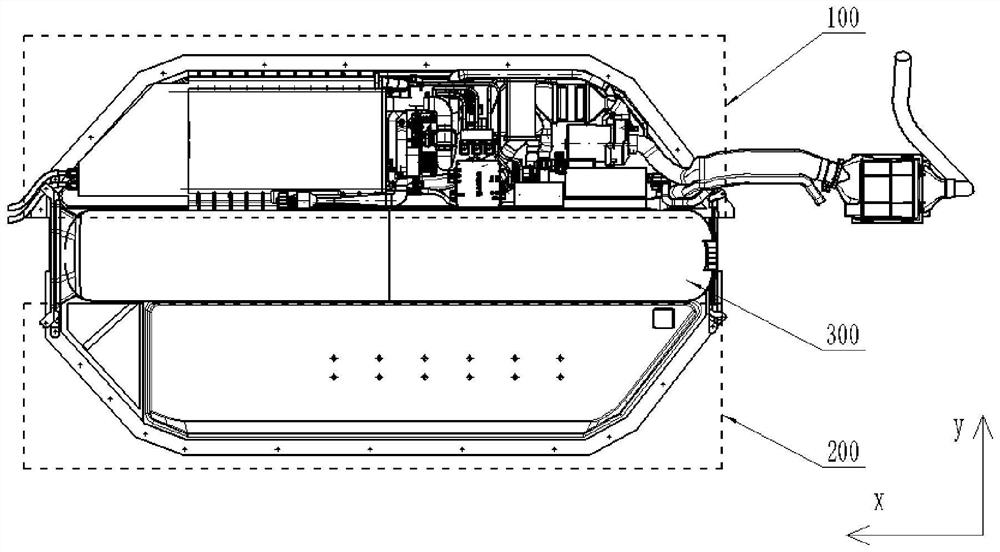

[0033] like figure 1 and figure 2 As shown, the power energy assembly provided by the embodiment of the present invention includes: a fuel cell system 100, a power battery system 200, and a hydrogen storage system 300;

[0034] The fuel cell system 100 and the power cell system 200 are arranged at intervals, and an installation area is formed between the fuel cell system 100 and the power cell system 200;

[0035] The hydrogen storage system 300 is installed in the installation area.

[0036] Specifically, the fuel cell system 100 and the power battery system 200 are figure 1 The central y-axis direction is spaced apart, and the hydrogen storage system 300 is installed between the fuel cell system 100 and the power battery system 200. The fuel cell system 100 and the power battery system 200 play a protective role for the hydrogen storage system 300, thereby reducing the risk of damage from the y-axis. The impact force in the direction improves the collision safety of the ...

Embodiment 2

[0051] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the power source assembly assembly method provided by the embodiment of the present invention includes:

[0052] The hydrogen storage system 300 is installed between the fuel cell system 100 and the power battery system 200 .

[0053] Specifically, the hydrogen storage system 300 is located between the fuel cell system 100 and the power battery system 200. When either of the fuel cell system 100 and the power battery system 200 is collided, the impact of the collision on the hydrogen storage system 300 can be mitigated , thereby improving the safety of the hydrogen storage system 300 in a collision.

[0054] In the embodiment of the present invention, the steps of installing the hydrogen storage system 300 between the fuel cell system 100 and the power battery system 200 include:

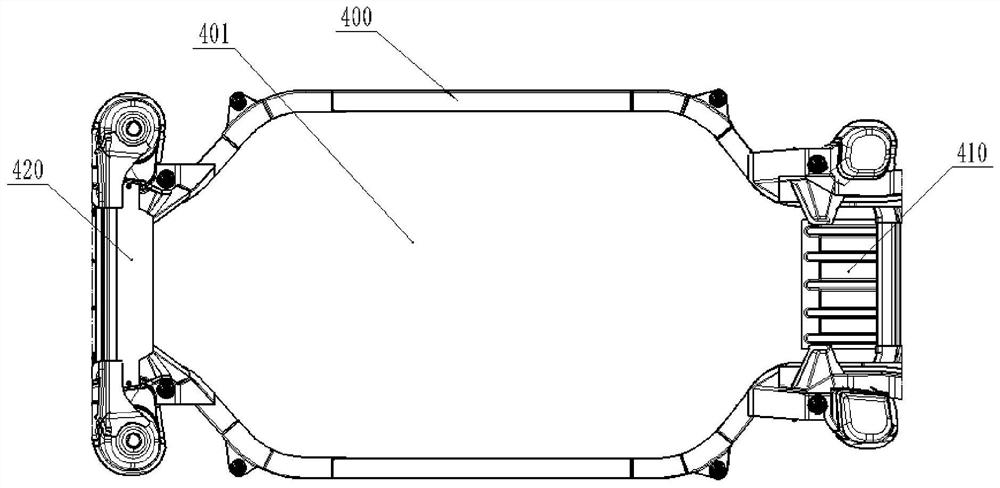

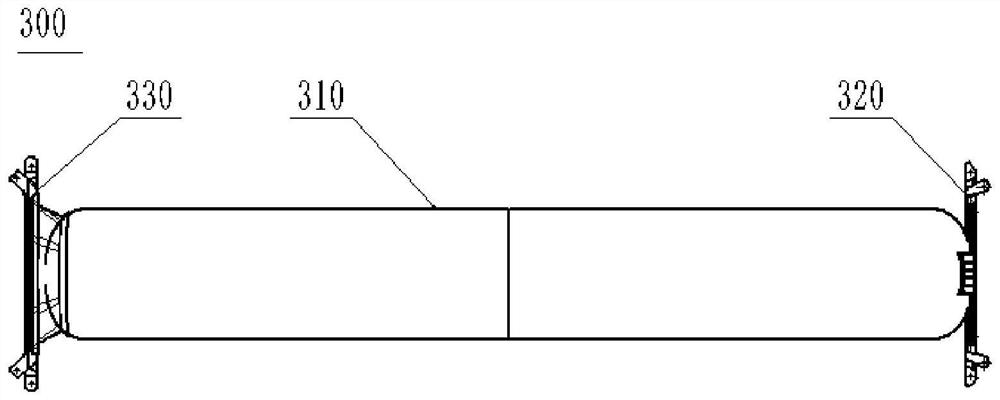

[0055] along the first direction, the hydrogen storage system 300 is installed in the accommodating space 401 su...

Embodiment 3

[0059] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the vehicle provided by the embodiment of the present invention is provided with the power energy assembly provided by the first embodiment.

[0060] The vehicle provided in this embodiment has the technical effect of the above-mentioned fuel cell system, which is not repeated here.

[0061] It should be noted that, along the traveling direction of the vehicle, both ends of the hydrogen storage system 300 are respectively connected to the chassis frame. Wherein, the protective frame 400 can be configured as a chassis frame, or the protective frame 400 can be used as a component of the chassis frame. When the vehicle is subjected to a frontal collision, the hydrogen storage system 300 can participate in the transmission of force, thereby improving the rigidity of the vehicle.

[0062] In addition, taking the traveling direction of the vehicle as the front view direction, one of the fuel cell sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com