Stepless air volume adjusting device of reciprocating compressor

A gas volume adjustment and compressor technology, which is applied in the field of compressors, can solve problems such as inconvenient operation, and achieve the effect of convenient installation and rapid installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

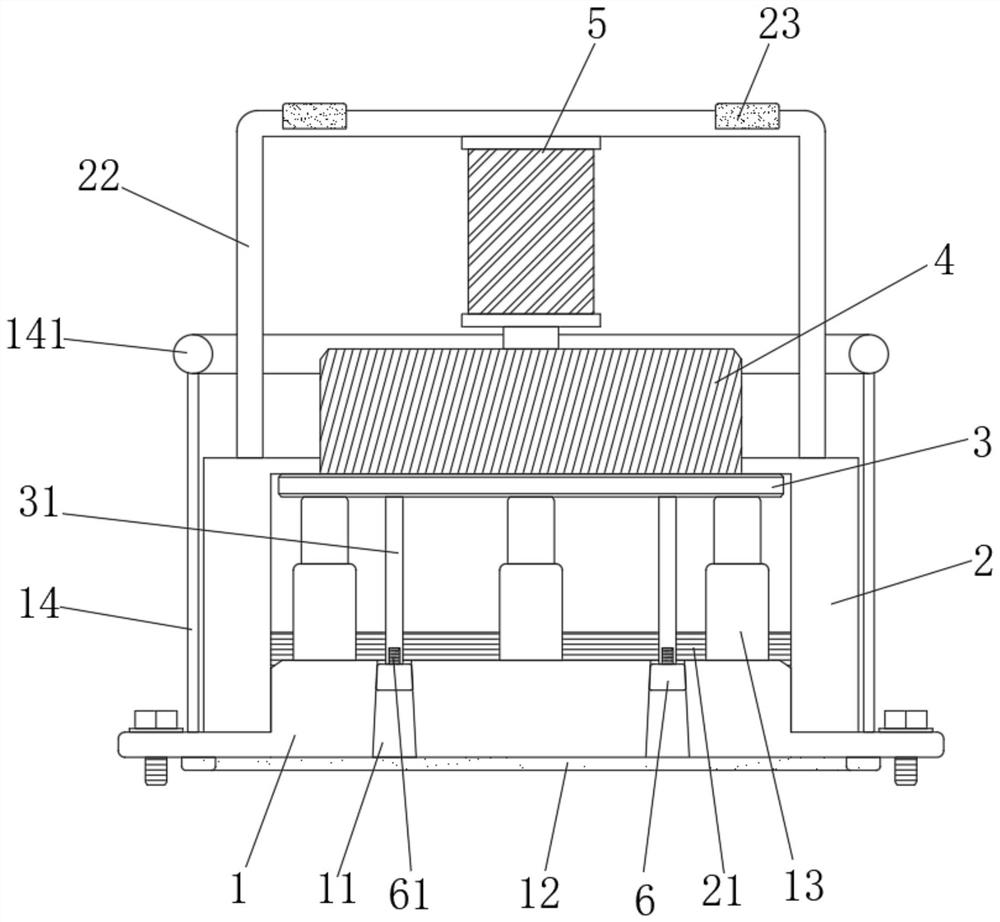

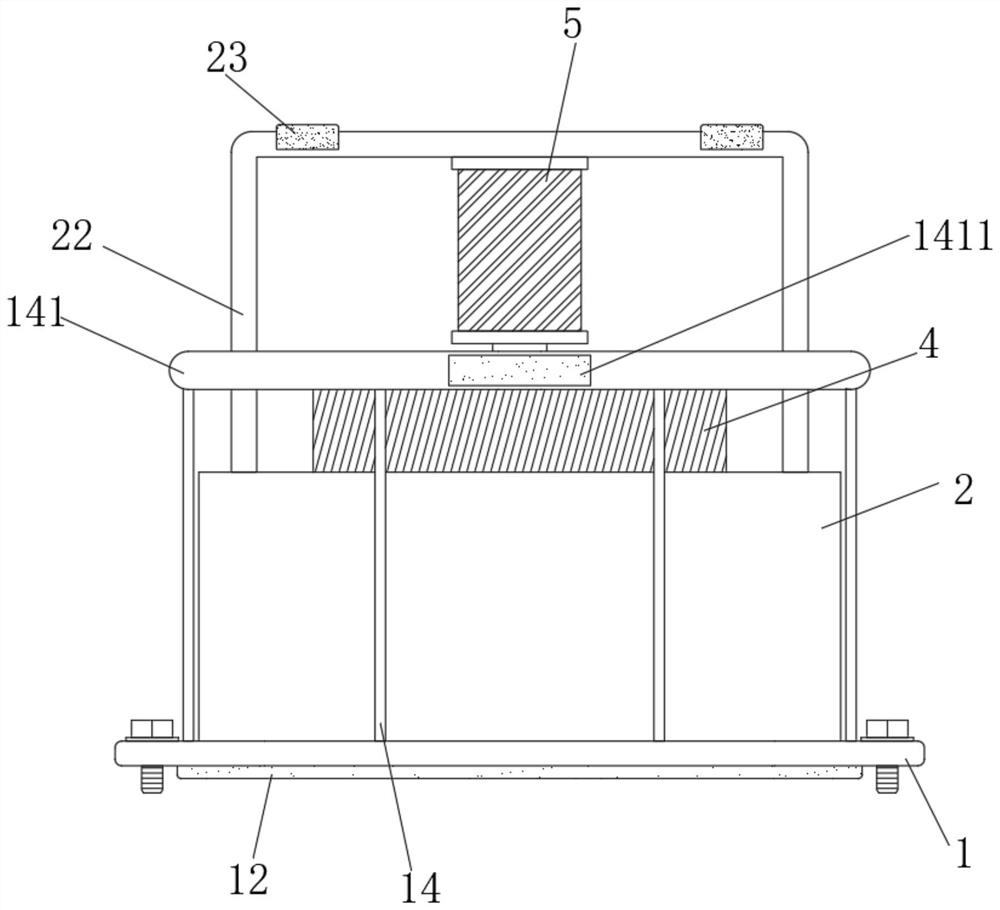

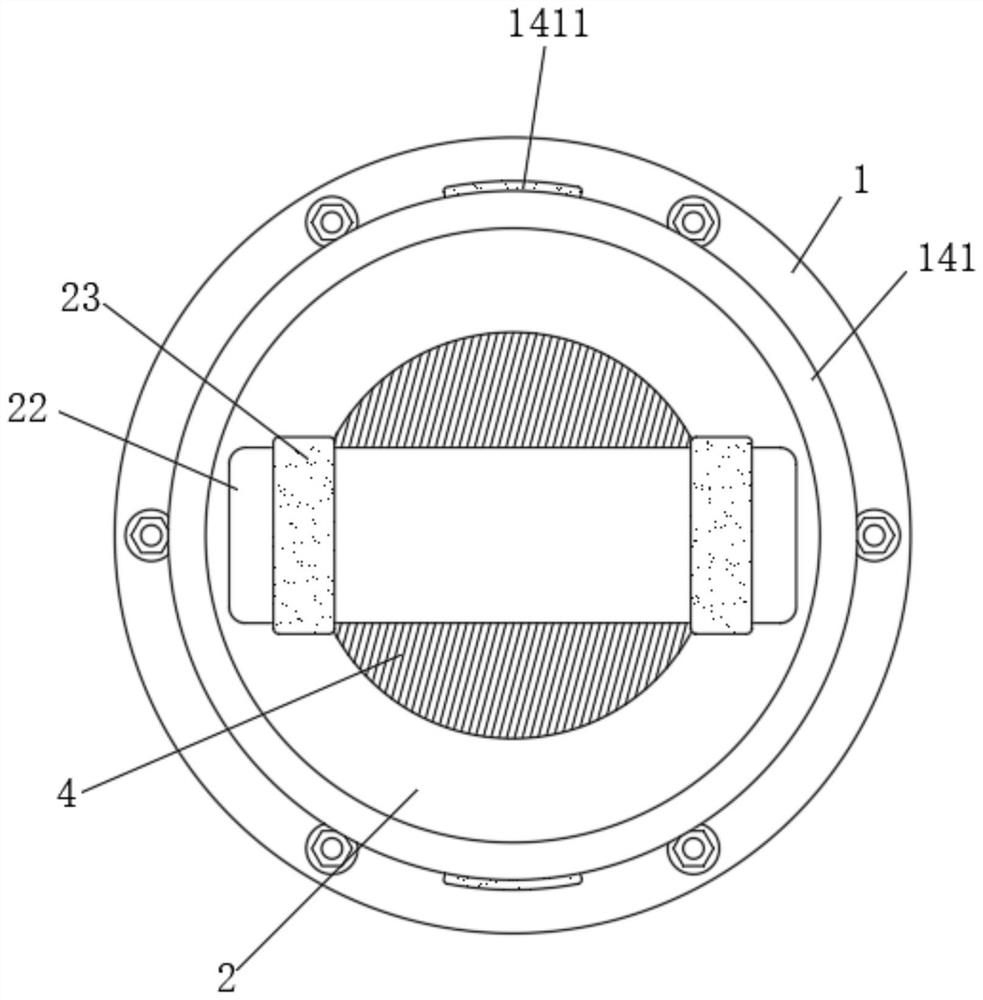

[0032] Example 1: see Figure 1-4 , the reciprocating compressor stepless air volume adjustment device of the present invention includes a valve seat 1, a connecting cylinder 2, a connecting plate 3, a hydraulic cylinder 5 and a piston 6, the surface of the valve seat 1 is provided with a plurality of air passages 11, the valve seat The surface of 1 is fixedly installed with a plurality of spring telescopic rods 13, the interior of the connecting cylinder 2 is opened as a cavity, the surface of the connecting cylinder 2 is engraved with a threaded road 21, the surface of the connecting cylinder 2 is fixedly connected with a fixing frame 22, and the connecting plate 3 The surface of the piston 6 is integrally formed with a connecting block 4, the surface of the connecting plate 3 is fixedly connected with a protruding rod 31, the hydraulic cylinder 5 is fixedly installed on the surface of the fixing frame 22, the surface of the piston 6 is provided with a threaded rod 61, and th...

Embodiment 2

[0033] Example 2: Unlike Example 1, see Figure 1-4, the valve seat 1 protrudes into the interior of the connecting cylinder 2, the valve seat 1 and the connecting cylinder 2 are threadedly connected, the surface of the valve seat 1 is fixedly connected with a plurality of connecting rods 14 in the vertical direction, and the plurality of connecting rods 14 are connected along the annular The first grab bar 141 is fixedly connected, and the surface of the first grab bar 141 is engraved with anti-skid lines. The first grab rod 141 can be grasped to apply pressure, and the first grab rod 141 and the connecting rod 14 can be used to drive the valve seat 1 to rotate inside the connecting cylinder 2, so that the connection between the valve seat 1 and the connecting cylinder 2 is more secure. That's it.

Embodiment 3

[0034] Example 3: Unlike Example 1 or 2, see Figure 1-4 , the bottom surface of the valve seat 1 is fixedly connected with the rubber ring 12 along the ring, the two sides of the top surface of the fixing frame 22 are fixedly connected with the second rubber pads 23, and the front and back positions of the surface of the first grab bar 141 are fixedly connected with a second rubber pad 23. A rubber pad 1411, the front and back of the second rubber pad 23 protrude to the front and back positions of the fixing frame 22 respectively. During use, the installation between the valve seat 1 and the corresponding equipment is used to make the rubber ring 12 The valve seat 1 and the corresponding equipment are more stable under pressure and have a partial resilience. At the same time, during the inversion operation, the first rubber pad 1411 or the second rubber pad 23 can be effectively used to realize the device. The isolation effect from the corresponding support point prevents acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com