Plunger sliding shoe and assembly process thereof

A technology of plunger and sliding shoe, which is applied in the field of plunger sliding shoe and its assembly technology, which can solve the problems of structural deformation, difficulty in grasping the gap between the sliding shoe and the plunger, etc., to reduce the weight, make the gap easier to control, and reduce the size of the cylinder overturning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

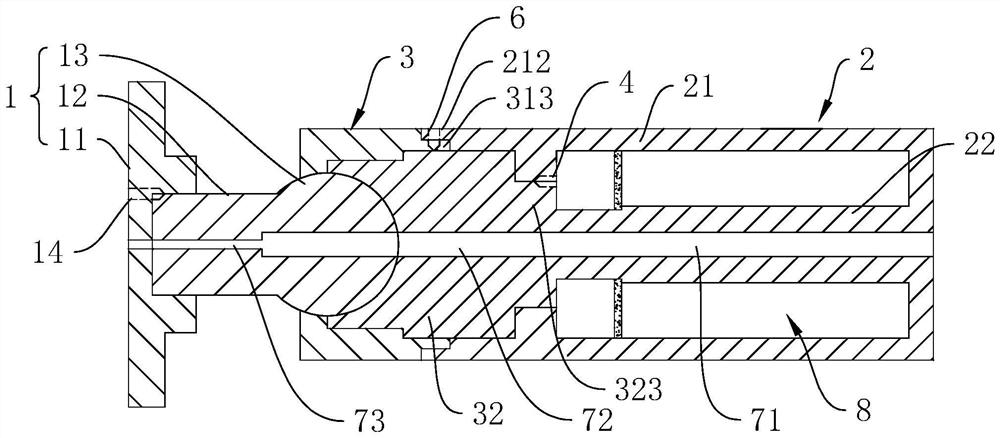

[0046] Attached to the following Figure 1-3 This application will be described in further detail.

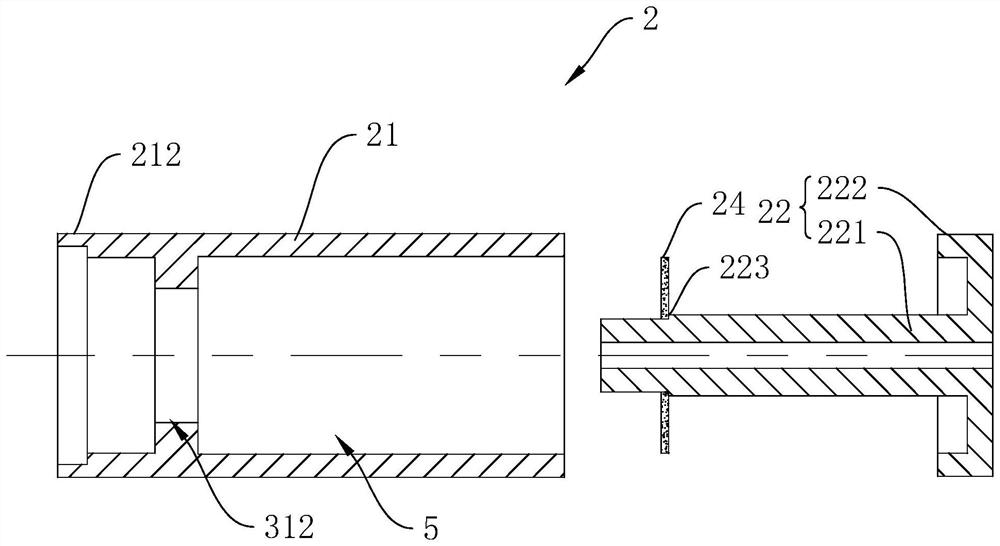

[0047] The embodiment of the present application discloses a plunger shoe. refer to figure 1 , including a sliding shoe 1 , a plunger 2 and a connecting assembly 3 arranged between the sliding shoe 1 and the plunger 2 .

[0048] The sliding shoe 1 includes a sliding shoe seat 11, a ball shank 12 and a ball head 13. The sliding shoe seat 11 is connected to the swash plate in the plunger pump. A second locking pin 14 is provided at the connection between the shoe seat 11 and the ball stud 12, and the second locking pin 14 is used to realize the fastening of the sliding shoe seat 11 and the ball stud 12, and the ball head 13 is integrally formed on the ball stud 12 is away from the end of the shoe base 11 .

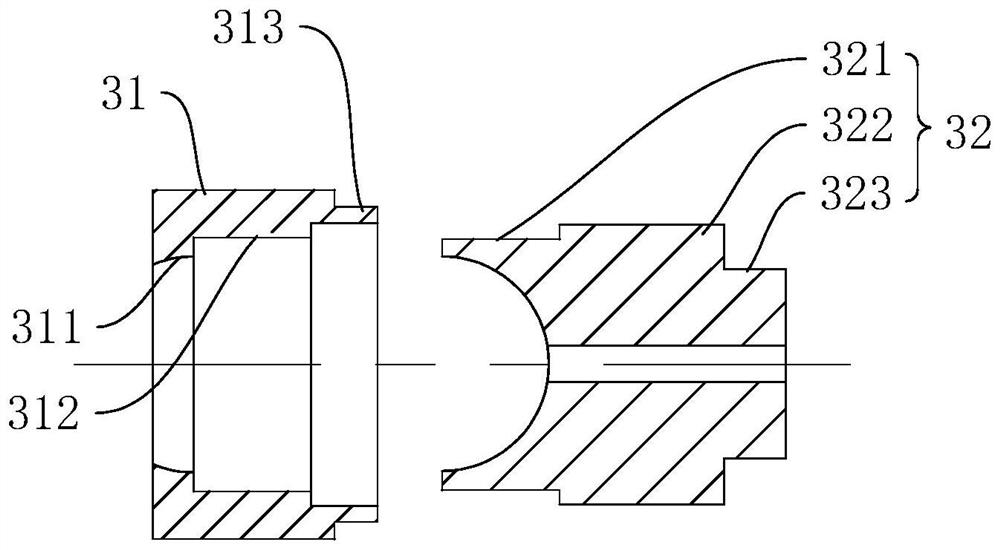

[0049] refer to figure 1 and figure 2 , the connection assembly 3 includes an outer connection sleeve 31 and an inner connection shaft 32, the outer connection sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com