Printing ink with multiple anti-counterfeiting effects as well as preparation method and application of printing ink

A kind of ink and multi-layer technology, applied in the field of new multi-mode and multiple anti-counterfeiting, can solve the problems of small application range, complicated production process, single anti-counterfeiting mode/effect, etc., and achieve the effect of huge application potential, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a method for preparing the ink with multiple anti-counterfeiting effects described in the above technical solution, comprising the following steps:

[0041] a) mixing molecules with macroscopic co-assembly ability, organic chiral dopants, inorganic light-emitting materials and solvents to obtain a mixed solution;

[0042] b) vacuum drying the mixed solution obtained in step a) to remove the solvent to obtain an ink with multiple anti-counterfeiting effects.

[0043]The present invention firstly mixes molecules with macroscopic co-assembly ability, organic chiral dopant, inorganic light-emitting material and solvent to obtain a mixed solution. In the present invention, the molecules with macroscopic co-assembly ability, organic chiral dopants, and inorganic light-emitting materials are the same as those in the above technical solutions, and will not be repeated here.

[0044] In the present invention, the solvent is preferably one or ...

Embodiment 1

[0063] 0.320g of organic chiral dopant S811, 0.040g of high-quality quantum dots and 0.600g of 4'-n-pentyl-4-cyanobiphenyl, a molecule with macroscopic co-assembly ability, were added to the open sample bottle in turn, and then Organic solvent toluene 1.0mL, ultrasonic for 15min to completely mix the components to form a uniform and transparent solution, then put the sample into a vacuum drying oven, slowly evaporate the solvent at 40 ℃ for 18h, and finally cool to room temperature to obtain a multi-information anti-counterfeiting effect of ink.

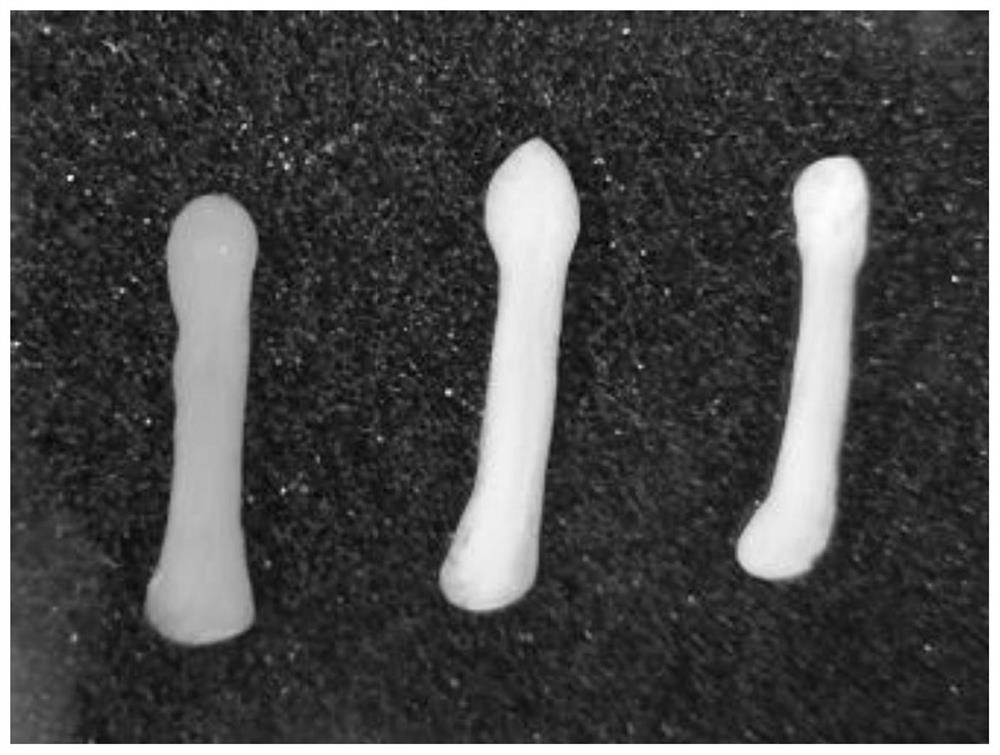

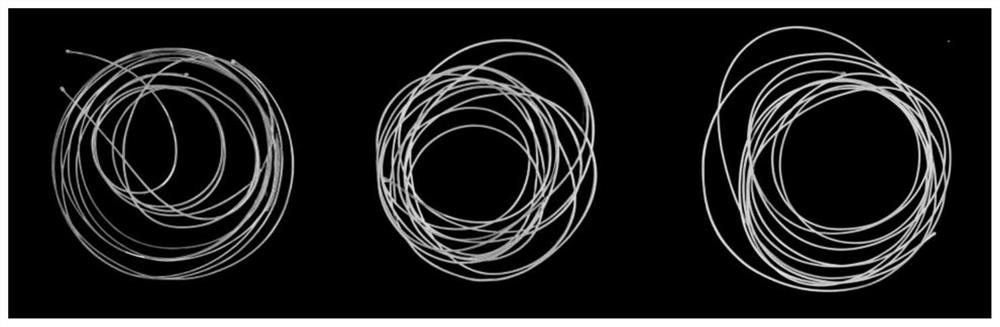

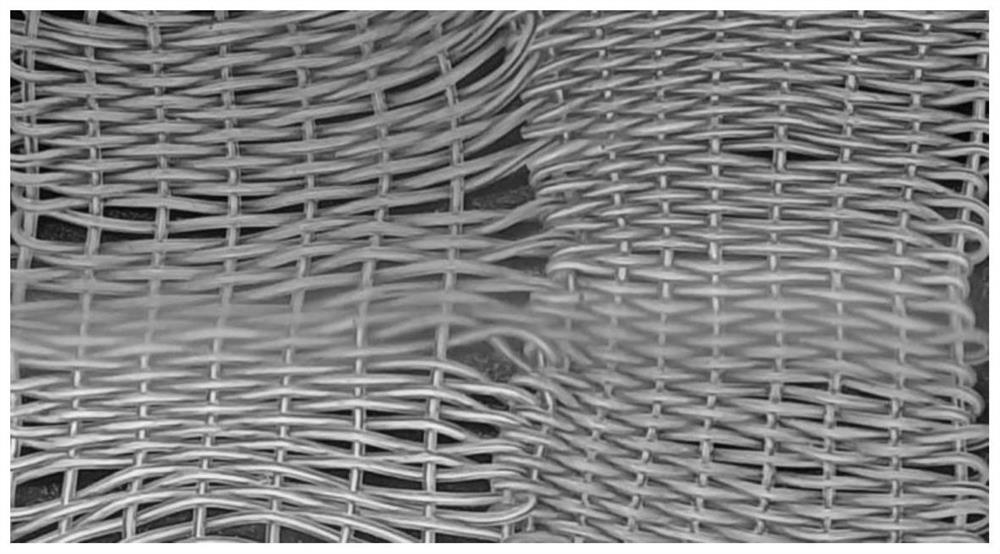

[0064] After testing, the clearing point transition temperature of the ink with the multi-information anti-counterfeiting effect provided in Example 1 of the present invention is 14.0°C, a blue structural color can be observed at 0.0-14.0°C, and the color changes to blue-violet when observed at 45°C. When a polarizer is added, the structural color disappears, and when an excitation light of 365 nm is applied, green fluorescence is em...

Embodiment 2

[0066] 0.300g of organic chiral dopant S811, 0.040g of high-quality quantum dots and 0.600g of 4'-n-pentyl-4-cyanobiphenyl, a molecule with macroscopic co-assembly ability, were added to the open sample bottle in turn, and then Organic solvent toluene 1.0mL, ultrasonic for 15min to completely mix the components to form a uniform and transparent solution, then put the sample into a vacuum drying oven, slowly evaporate the solvent at 40 ℃ for 18h, and finally cool to room temperature to obtain a multi-information anti-counterfeiting effect of ink.

[0067] After testing, the clearing point transition temperature of the ink with multi-information anti-counterfeiting effect provided by Example 2 of the present invention is 18.0 ° C, a green structural color can be observed at 0.0-18.0 ° C, and the color changes to indigo cyan when observed at 45 ° C. When the polarizer is used, the structural color disappears, and when an excitation light of 365 nm is applied, green fluorescence i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com