Composite production line of automobile top interior trim assembly

A production line and interior decoration technology, applied in the direction of layered products, thin material processing, lamination auxiliary operations, etc., can solve the problems of difficult to realize automatic processing operations, high space occupancy, low production efficiency, etc., to save workshops, The effect of reducing the number of workshops and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

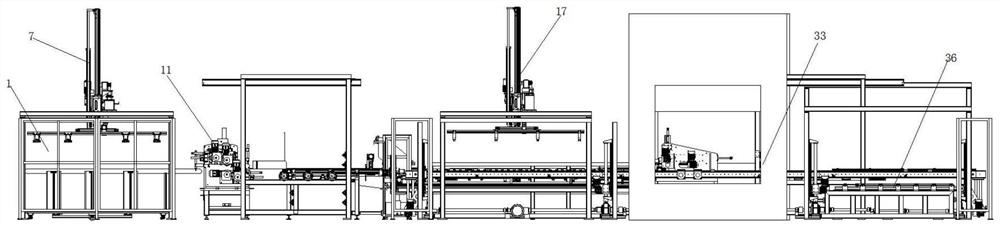

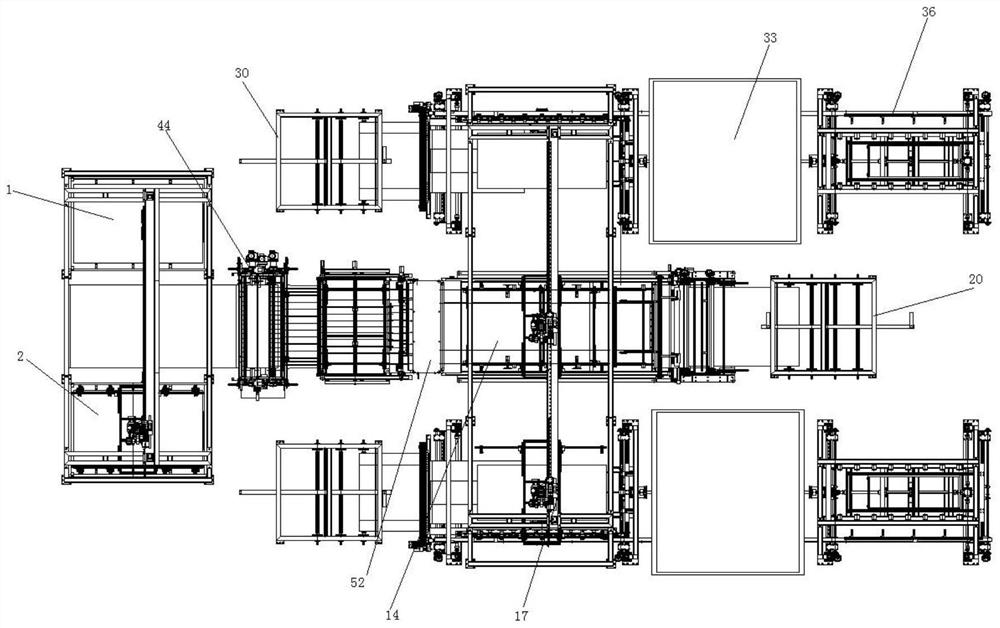

[0029] Example 1, as figure 1 and figure 2 As shown in the figure, a composite production line for automobile top interior assembly includes a set of forming frame transfer stations, a pressing unit corresponding to each forming frame transfer station, and an auxiliary material connected to each pressing unit. The material station, the coil cutting station connected to each auxiliary material feeding station, the double-station acupuncture feeding table structure connected to the rear end of the coil cutting station, and the acupuncture feeding table structure located at the double station The middle common line adjustment structure is connected and arranged between the workpiece pressing mechanism, the auxiliary material feeding station, and the coil cutting station. The PU transplanting centering station connected to the collinear station of the PU board rolling, gluing, and loading line is a collinear station for coil cutting.

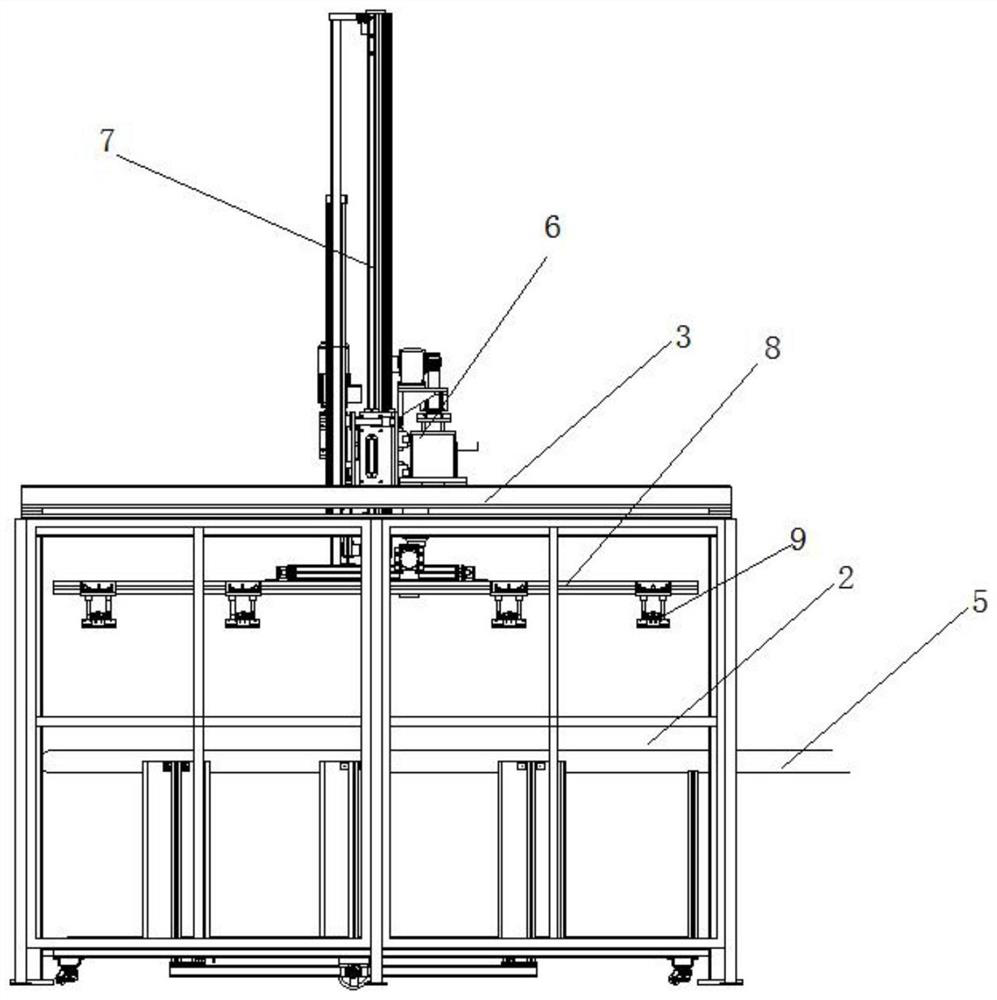

[0030] like image 3 and Figure 4 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com