Application method of mvr heat pump evaporation salt production in multi-effect vacuum salt production technology

A heat pump evaporation and vacuum salt production technology, applied in the field of salt production, can solve the problems of large investment in new construction and waste of assets, and achieve the effects of short investment recovery period, energy saving and equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

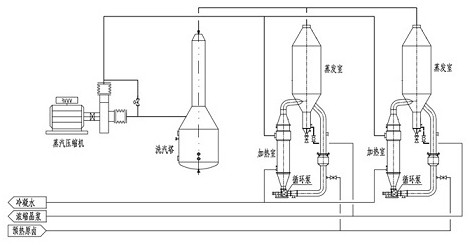

[0051] like figure 2 As shown, the evaporation and crystallization process of MVR heat pump evaporation salt production in the multi-effect vacuum salt production technology, the specific steps include:

[0052] 1. The sea salt from the salt pond is sent to the salt washing yard for temporary storage after the salt washing process; the temporarily stored solid salt enters the disc feeder through the raw salt hopper and is quantitatively fed to the raw salt belt; conveyed by the raw salt belt It is mixed with the condensed water from the evaporation device, dissolved, and made into refined brine, which enters the evaporation and drying system.

[0053] 2. The brine temporarily stored in the brine pool is pumped to the filter for filtration, and the filtered brine enters the mixing tank to become brine; the brine in the mixing drum is pumped to the secondary pre-treatment by the mixing pump. After the heater exchanges heat with the condensed water and increases the temperature...

Embodiment 2

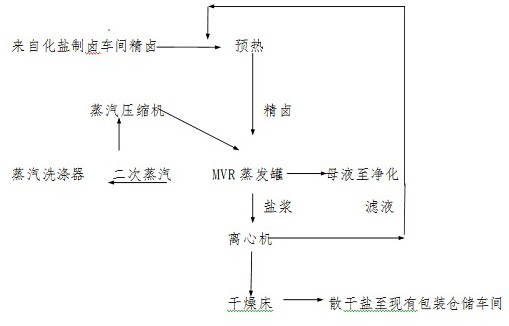

[0070] like figure 1 As shown, the brine treatment process of MVR heat pump evaporation salt production in the multi-effect vacuum salt production technology, the specific steps include:

[0071] 1. The brine with the NaCl content of 310 g / L obtained after dissolving the original salt is input into the reaction barrel, the soda ash is added to adjust the pH value to 8, and then the brine is input into the clarification barrel and clarified to obtain the upper layer of refined brine;

[0072] 2. The upper layer of refined brine is transported to the refined brine tank, and is pumped to the preheater through the mixing pump. The refined brine is preheated to 98-101 °C and then enters the circulation pipe for forced circulation, and then enters the five-effect evaporation system;

[0073] 3. In the five-effect evaporation system, the steam pressure at the outlet of the compressor is controlled at 169.1kpa, and the pressure in the evaporation chamber is controlled at -0.001Mpa. Af...

Embodiment 3

[0077] like image 3 As shown, the steam treatment process of MVR heat pump evaporation salt production in the multi-effect vacuum salt production technology, the specific steps include:

[0078] 1. There are two raw steams from the boundary area. The first raw steam enters the MVR evaporation device as a heat source for system startup and a supplementary heat source for the normal operation of the system; the second raw steam enters the air preheater for preheating. Air, as the heat source of the drying system;

[0079] The volume ratio of the first raw steam to the second raw steam is 1:1.

[0080] 2. The secondary steam evaporated from each effect is respectively removed by the demister to remove the entrained mist, and then aggregated into the gas scrubbing tower. After being washed by the circulating condensed water in the scrubbing tower, it enters the steam compressor. compression;

[0081] The inlet medium of the steam compressor is saturated water vapor, the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com