Line-side clamp centering and positioning device

A centering positioning and fixture technology, which is applied to auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems that the centering positioning device cannot be used for line-side positioning, and there are few applicable models, so as to improve the utilization rate and repeat positioning accuracy High and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

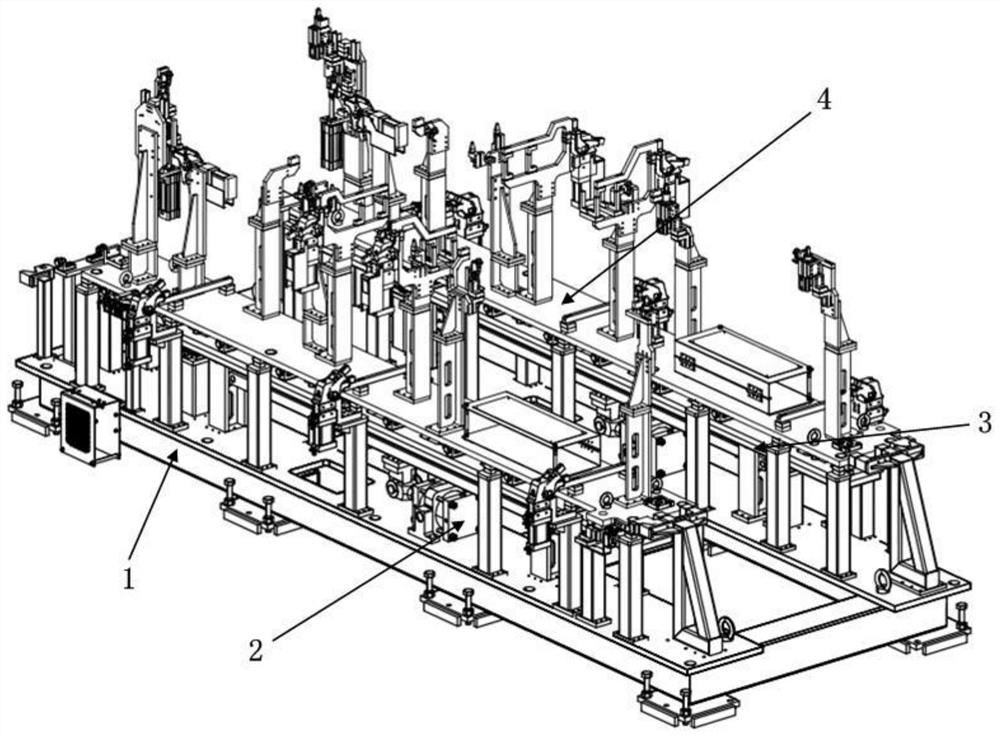

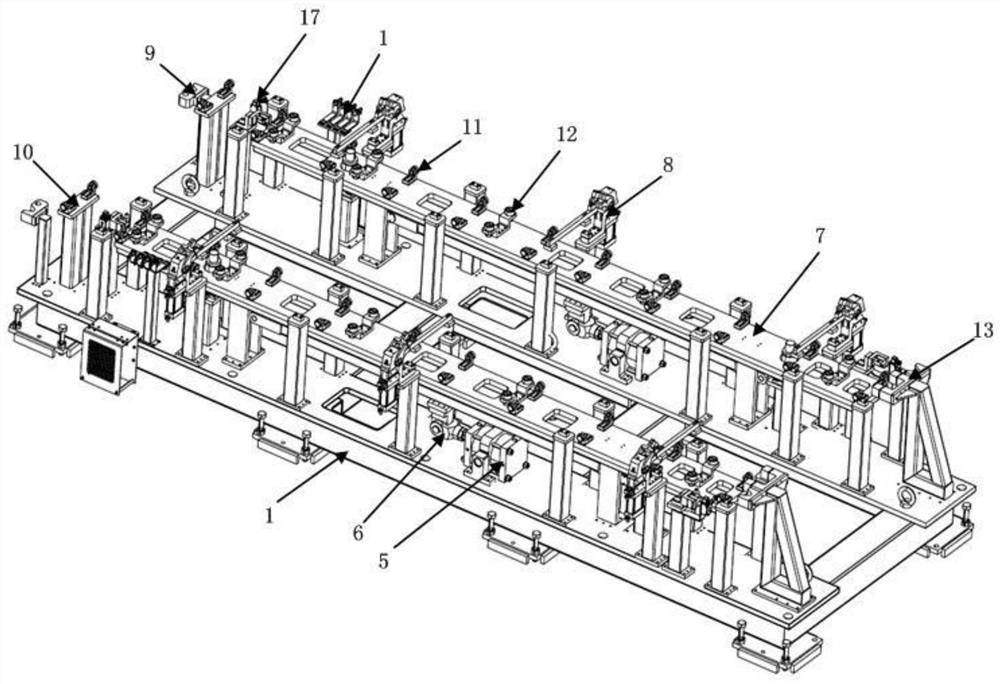

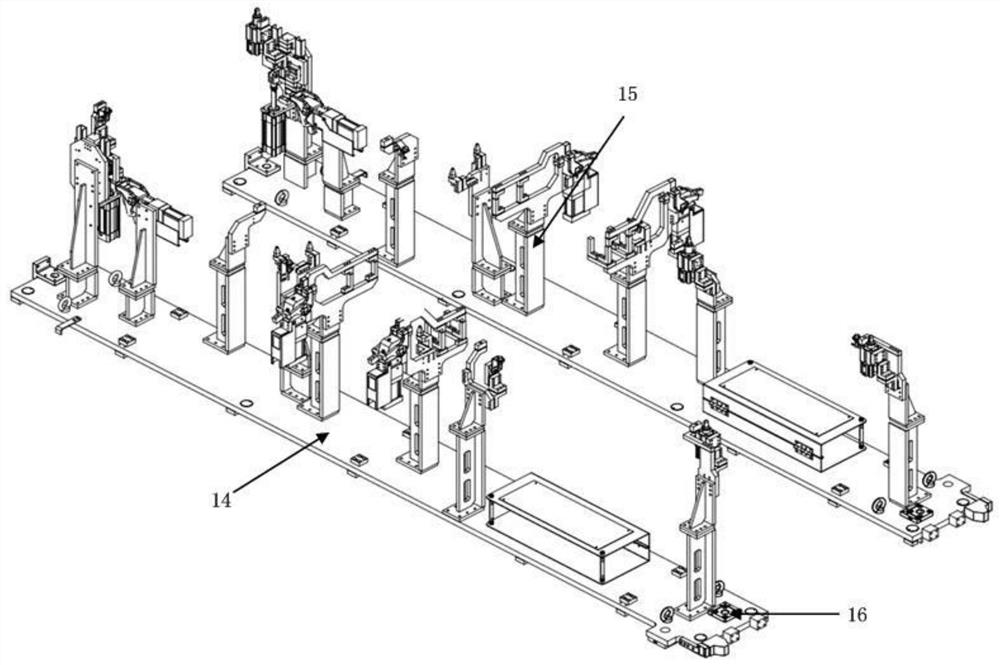

[0016] Description of drawings: 1-base, 2-lifting mechanism, 3-positioning mechanism, 4-fixture mechanism, 5-lifting cylinder, 6-eccentric wheel, 7-base plate, 8-clamping piece, 9-butting block , 10-transition block, 11-roller, 12-limit wheel, 13-limit block, 14-fixture plate, 15-fixture, 16-positioning hole, 17-positioning pin.

[0017] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to directions in the drawings, and the words "bottom" and "top" "Face", "inner" and "outer" refer to directions toward or away from the geometric center of a particular part, respectively.

[0018] like Figure 1-3 As shown, the present invention provides a line-side clamp centering and positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com