Low-pressure casting mold for aluminum gear chamber

A low-pressure casting and gear chamber technology, which is applied in the manufacture of tools, casting equipment, mechanical cleaning, etc., can solve the problems of low yield rate of molten aluminum, high shrinkage of products, and large thermal joints of the bosses in the inner cavity of gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

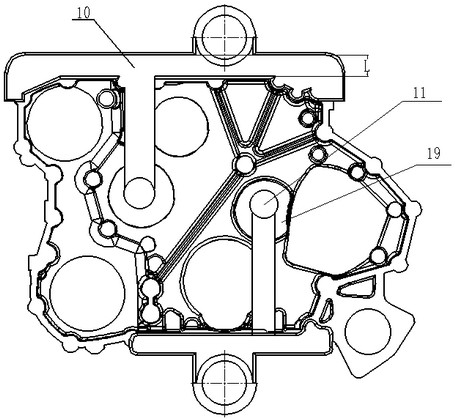

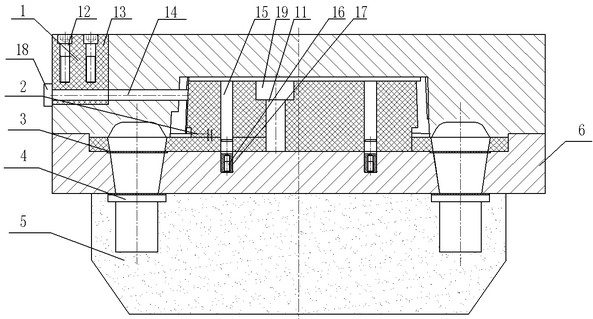

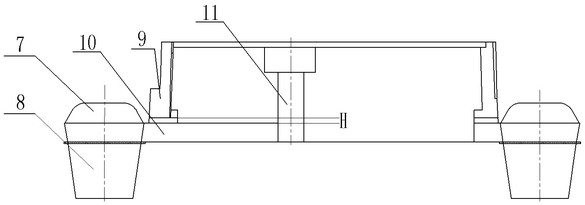

[0019] figure 1 , 2 , 3, the present invention includes a metal mold composed of an upper mold 1 and a lower mold 6, and a gear inner cavity sand core 2 located in the metal mold cavity. The lower mold 6 is provided with two lower sprues, and the lower mold cylindrical pins (ie, positioning pins) 17 are positioned in cooperation with the sand core positioning holes 15. The runner inlet is connected to the ceramic liquid riser 4 . The lower part of the sand core in the inner cavity of the gear is provided with a middle sprue, a runner 10 and a gear feeding runner 11 . The runner 10 includes a horizontal runner section and a vertical runner section, and the cross-sections of the horizontal runner section and the vertical runner section are square. One side of the gear inner cavity sand core 2 forms the gear inner cavity shape of the joint surface of the flywheel shell, and the other side of the gear inner cavity sand core 2 is provided with the gear feeding runner 11 connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com