Dust removal system for removing and purifying sintering flue gas pollutants

A technology of sintering flue gas and dust removal system, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of low automation, low efficiency, high energy consumption, inconvenient control and operation, etc., and achieve service life Long, meet the process requirements, improve the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

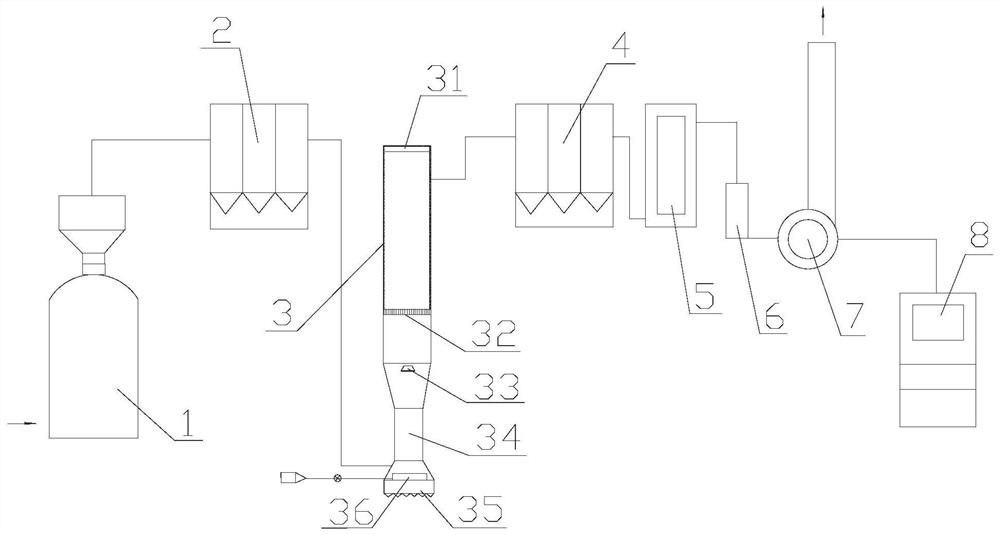

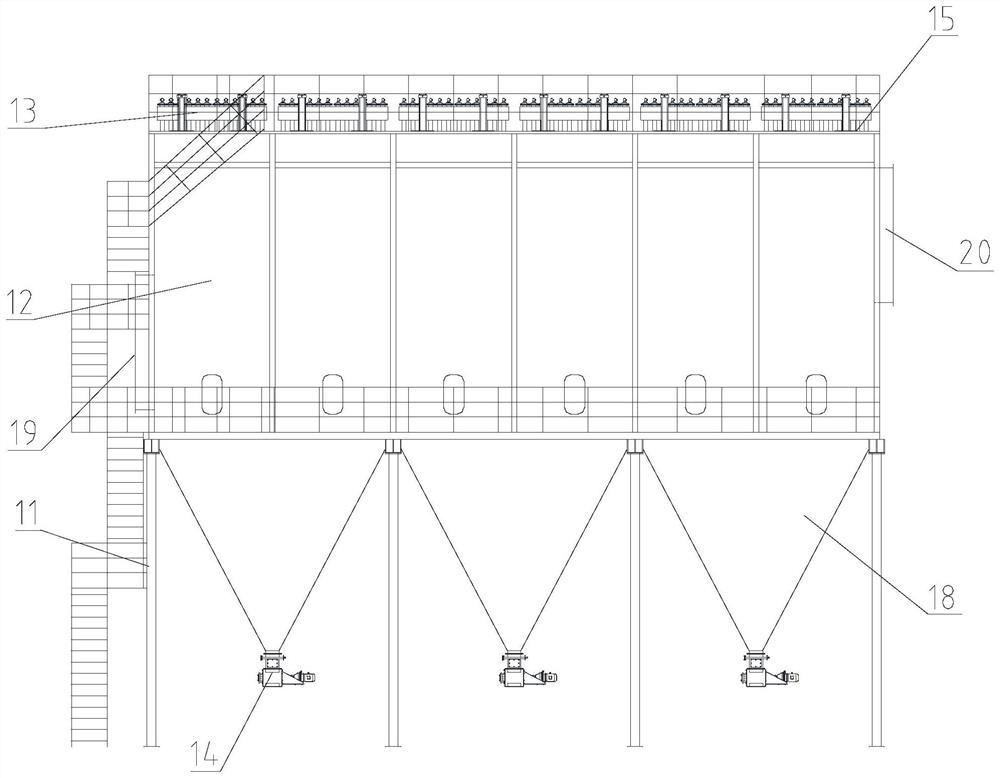

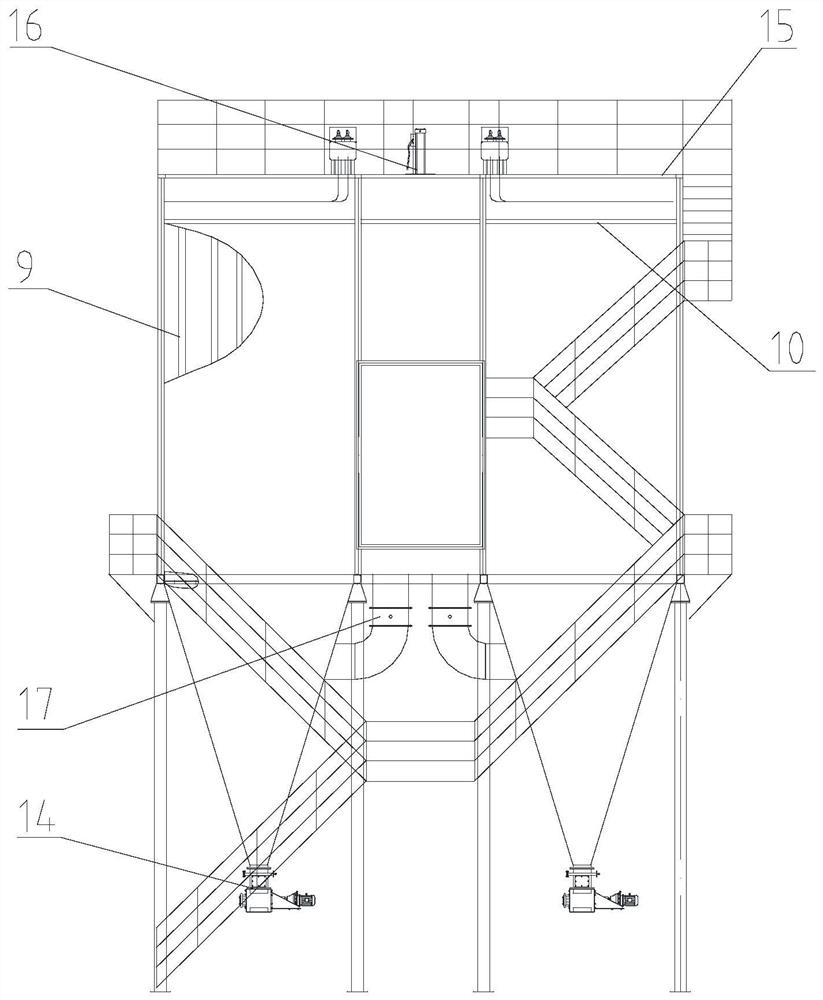

[0023] like Figure 1 to Figure 3 As shown, a dust removal system for removing and purifying sintering flue gas pollutants includes a quench tower 1, a first dust collector 2, an absorption tower 3 and a second dust collector 4 connected in sequence, the first dust collector 2 and the second dust collector 4 The dust collectors 4 are all electrically connected to the control cabinet 8; the absorption tower 3 is set as an upper, middle and lower three-part structure, and the upper inner wall of the absorption tower 3 is fitted with a removable active coke purification filter layer 31, and an active coke purification filter layer 31 is attached to the inner wall of the absorption tower 3. The purification filter plate 32, the lower part of the absorption tower 3 is provided with a desulfurizing agent storage 36, a venturi tube 34 and a water spray nozzle 33; the second dust collector 4 is connected to the air purification device 5, and the air purification device 5 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com