Automatic backwashing and filtering device and method of low-temperature multi-effect distillation seawater desalination system

A multi-effect distillation and filtration device technology, which is applied to chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems that the filtration device cannot be operated efficiently and stably for a long period, the structure of the filtration device is single, and the degree of automation is low. Achieve the effects of delaying disassembly and cleaning frequency, improving backwashing effect, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

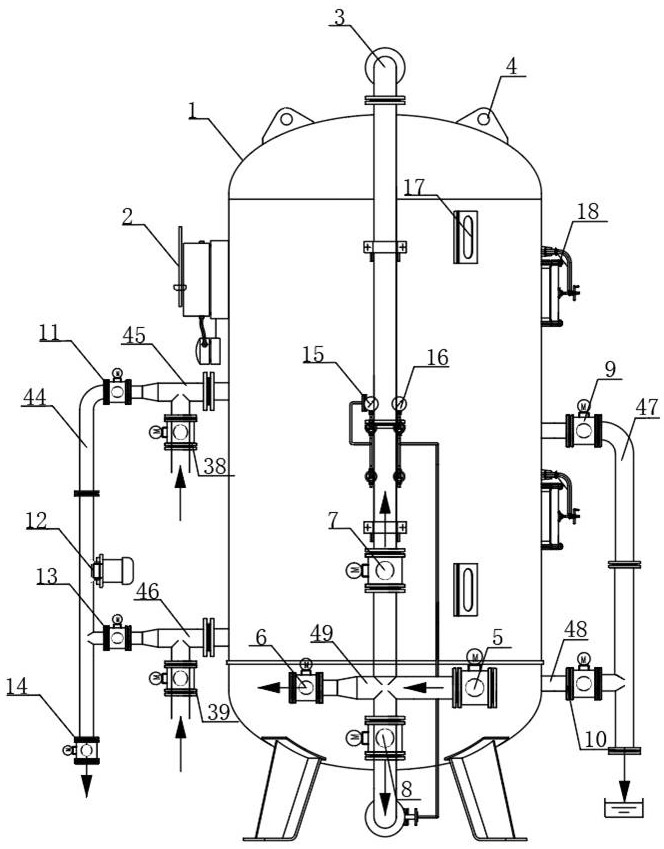

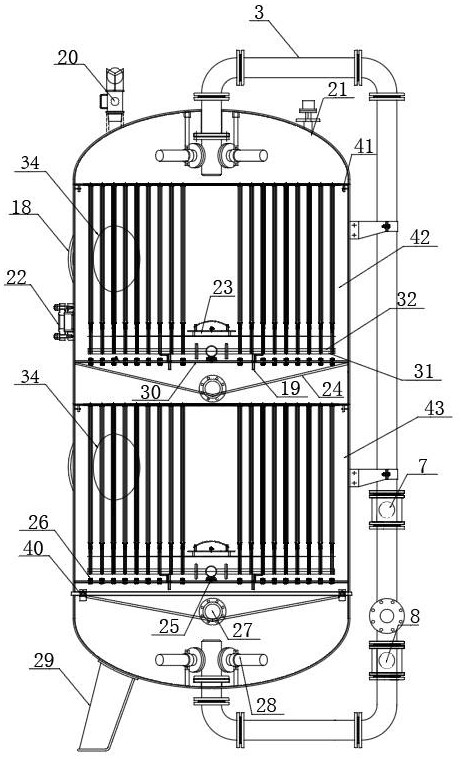

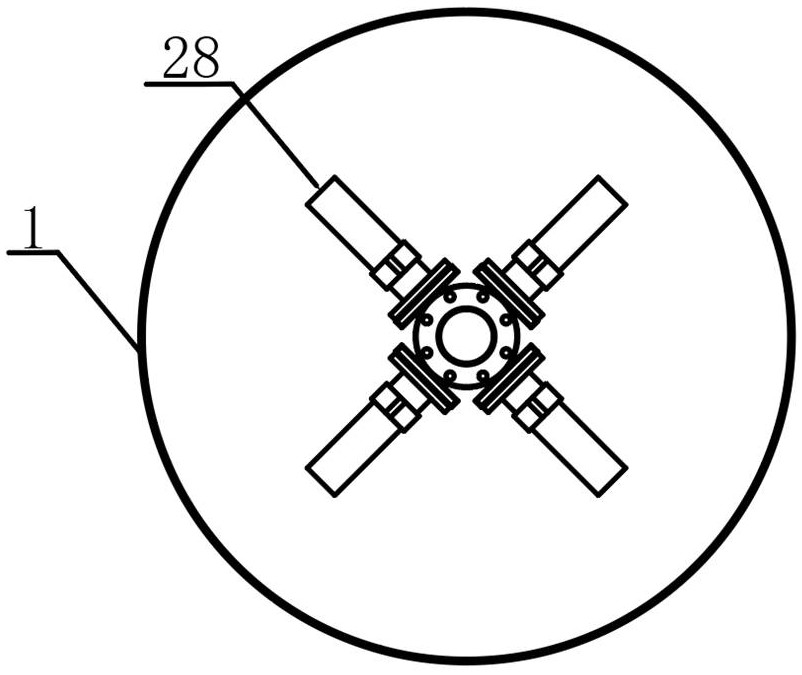

[0060] figure 1 is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the left side sectional structure of the present invention, image 3 It is a schematic view of the vertical cross-sectional structure of the present invention, such as figure 1 , figure 2 and image 3 The shown low-temperature multi-effect distillation seawater desalination system automatic backwash filter device includes a shell 1, an automatic control device 2, a water inlet pipe 3, a water outlet pipe 44, a sewage pipe 47 and a filter device, and the automatic control device 2 is connected to the shell. 1 side, the water inlet pipe 3 is arranged at the front end of the casing 1, the two ends of the water inlet pipe 3 are respectively connected with the upper and lower ends of the casing 1, and the water outlet pipe 44 and the sewage pipe 47 are respectively connected to the two sides of the casing 1. side, the filter device is installed inside the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com