Micronization method for extruding and stabilizing rice bran

A stabilized and stabilized treatment technology, applied in the field of food processing, can solve the problems of serious time-consuming wet micro-powder, damage of heat-sensitive substances, limited processing precision, etc., and achieve the effect of improving bioavailability, digestibility and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

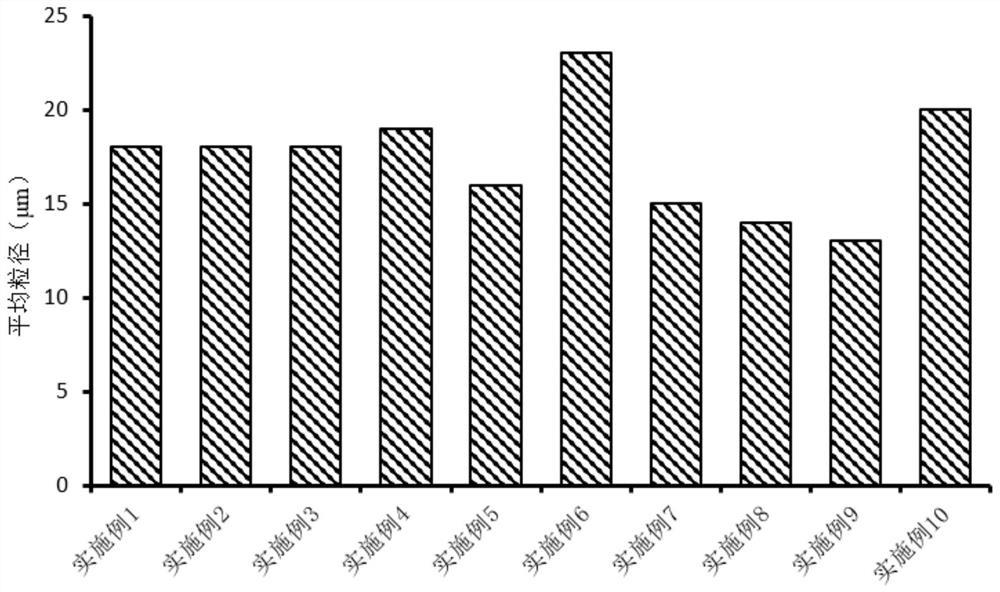

[0034] After the fresh rice bran is removed from impurities, the rice bran is processed by extrusion stabilization technology, and the processing temperature is 110° C. and the time is 3 s. Put the obtained extrusion-stabilized rice bran into a pulverizer, add liquid nitrogen into the pulverizing cavity of the pulverizer, and continuously pulverize for 3 minutes to obtain coarse rice bran powder. The obtained coarse rice bran powder and distilled water were mixed in a ratio of 1:10, added to a colloid mill, and ultra-finely pulverized by a wet method for 15 minutes to obtain wet rice bran powder. The wet rice bran powder was passed through a 200-mesh sieve to remove some large particles, and then dried at 60°C to obtain micronized rice bran, and the drying time was 1.5h.

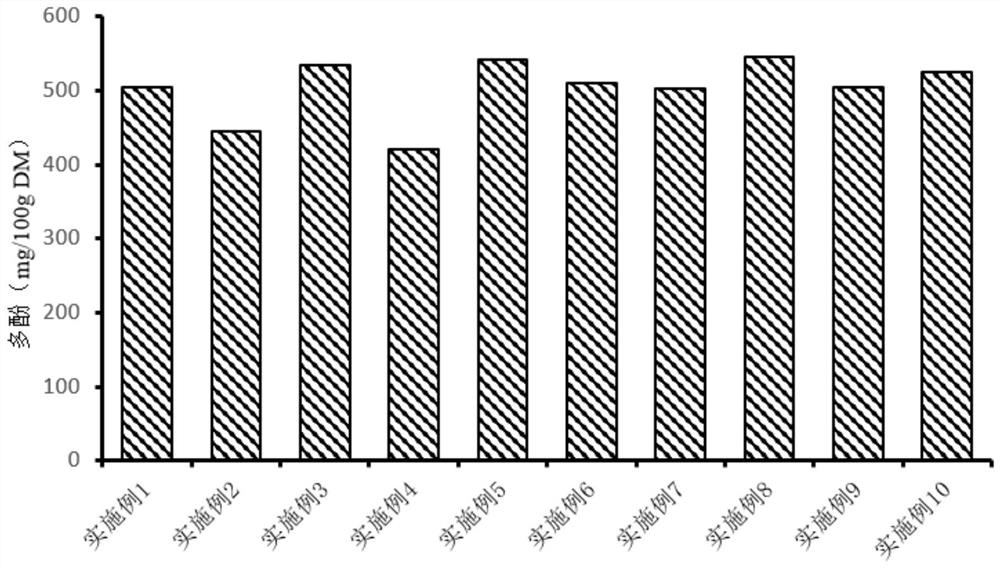

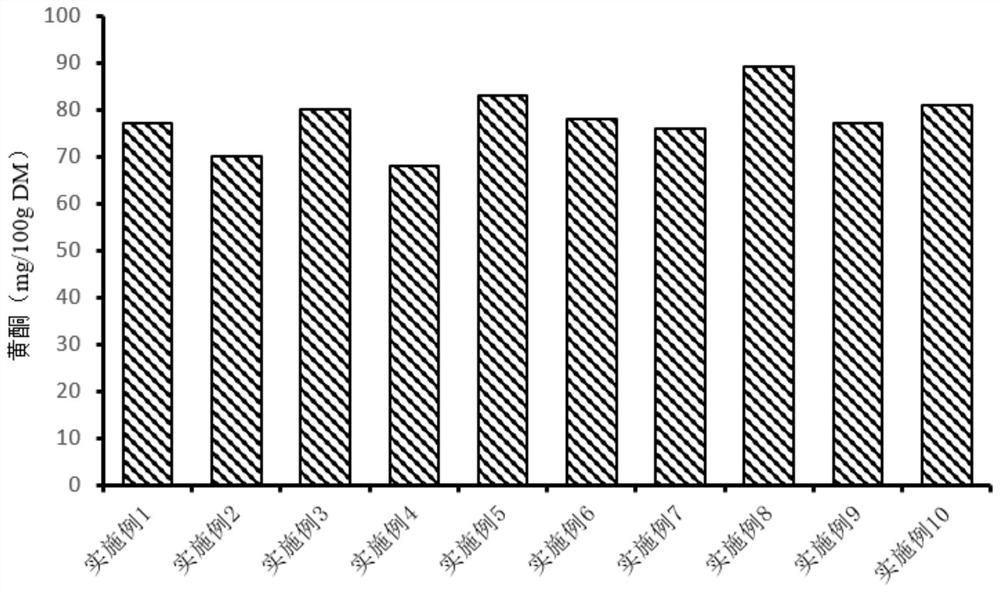

[0035] The micronized rice bran has a particle size of about 18 μm, has a delicate taste and is rich in nutrients, and can be used as a raw material for rice bran bread, rice bran biscuits, and rice bran bev...

Embodiment 2

[0037] After the fresh rice bran is removed from impurities, the rice bran is processed by extrusion stabilization technology, and the processing temperature is 120° C. and the time is 3s. Put the obtained extrusion-stabilized rice bran into a pulverizer, add liquid nitrogen into the pulverizing cavity of the pulverizer, and continuously pulverize for 3 minutes to obtain coarse rice bran powder. The obtained coarse rice bran powder and distilled water were mixed in a ratio of 1:10, added to a colloid mill, and ultra-finely pulverized by a wet method for 15 minutes to obtain wet rice bran powder. The wet rice bran powder was passed through a 200-mesh sieve to remove some large particles, and then dried at 60°C to obtain micronized rice bran, and the drying time was 1.5h.

Embodiment 3

[0039] After removing impurities from the fresh rice bran, the rice bran was treated by extrusion stabilization technology, and the treatment temperature was 100° C. and the time was 3 s. Put the obtained extrusion-stabilized rice bran into a pulverizer, add liquid nitrogen into the pulverizing cavity of the pulverizer, and continuously pulverize for 3 minutes to obtain coarse rice bran powder. The obtained coarse rice bran powder and distilled water were mixed in a ratio of 1:10, added to a colloid mill, and ultra-finely pulverized by a wet method for 15 minutes to obtain wet rice bran powder. The wet rice bran powder was passed through a 200-mesh sieve to remove some large particles, and then dried at 60°C to obtain micronized rice bran, and the drying time was 1.5h.

[0040] Since extrusion stabilization inactivates lipoxygenase, it also promotes the Maillard reaction of rice bran, resulting in a unique color and flavor. Through the comparison of Examples 1-3, under the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com