Cold plate liquid cooling intelligent heat dissipation regulation and control system, regulation and control optimization method and device

A control system, liquid cooling technology, applied in the direction of cooling/ventilation/heating transformation, modification with gaseous coolant, electrical components, etc., can solve the problems of flow waste liquid cold plate, excessive flushing of pipelines, and shortened service life. Achieve the effect of reducing overreaction, simple structure, and optimal control of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

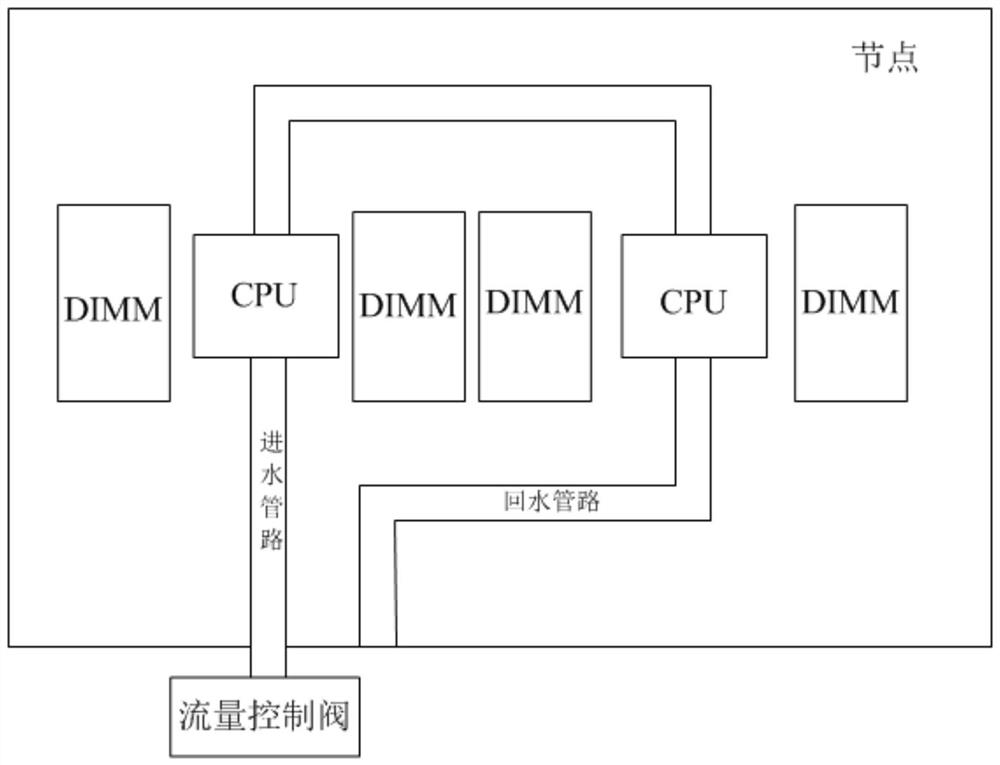

[0061] The existing cold plate system uses the CDU system outside the whole cabinet to adjust the flow into each node in the system. There are generally 40 node servers in a whole cabinet. At present, the flow control method of the same pipe diameter is only applied to Scenarios with the same node type and the same work pressure severely limit its usage scenarios. As the complexity of the cabinet increases, an intelligent cooling control strategy to solve this problem is urgently needed. It avoids that the flow of the entire node system will increase due to the overheating of the components of a certain node, resulting in waste of flow. Excessive flow increases the burden on the flow control valve, increases the pressure of the entire pipeline, and increases the risk of leakage, and The heat dissipation power consumption will also increase, which increases the PUE value and reduces the service life of the pipeline. What is more worrying is that the increase of the flow of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com