Sectional control system for extremely low tension of tows in tow placement equipment

A segmented control and tension technology, which is used in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problem of inability to achieve low-tension laying operations, prone to bridging, overturning, and easy tow wear. and other problems, to achieve the effect of improving the laying quality, increasing the practicability, and stabilizing the structure of the parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

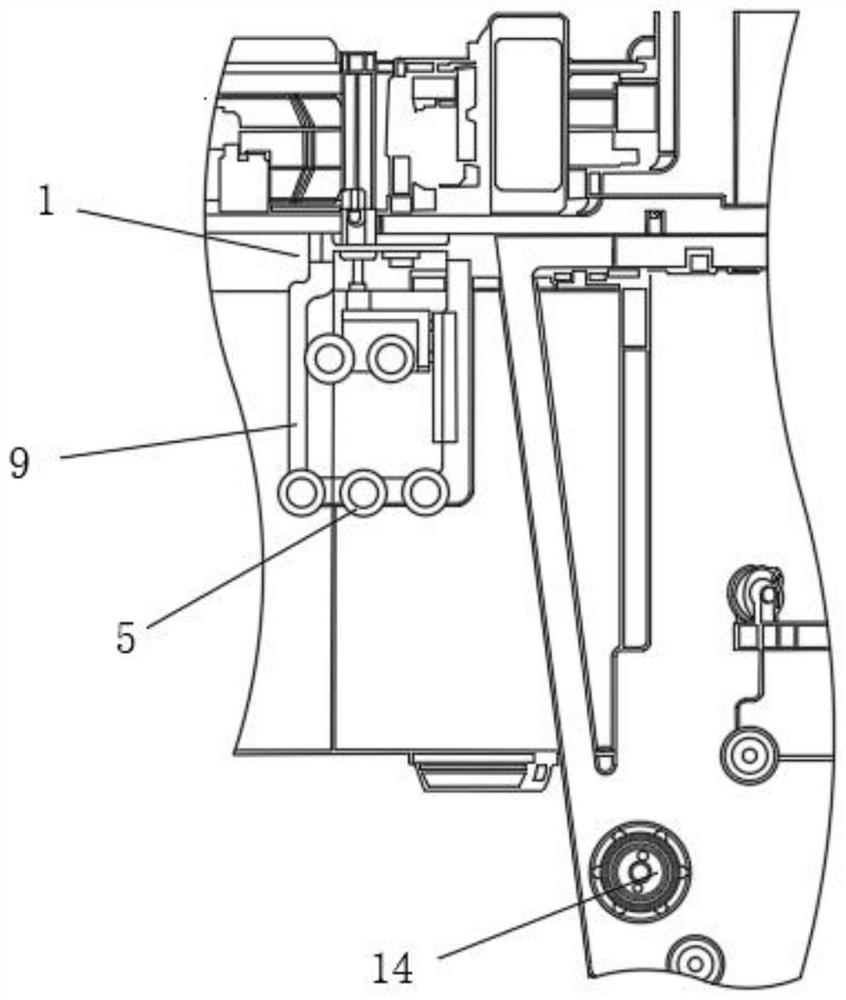

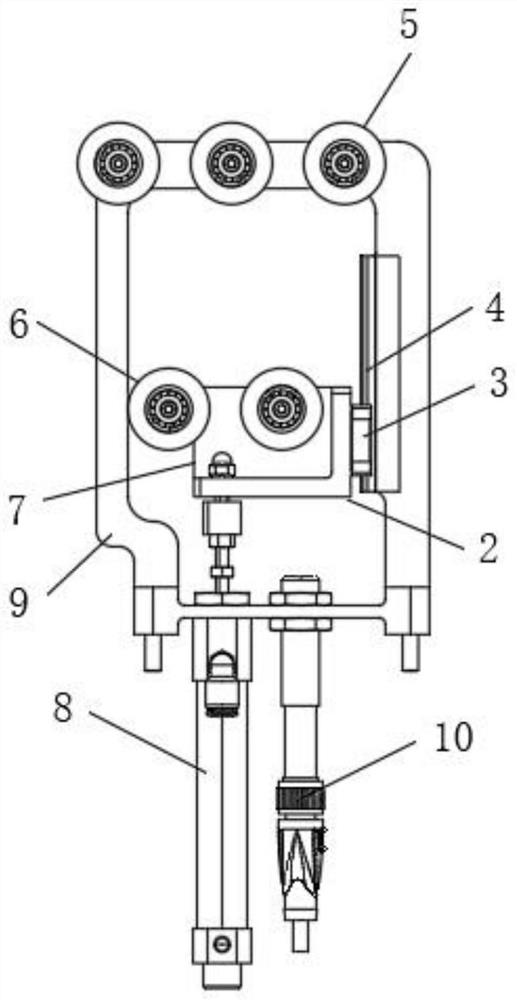

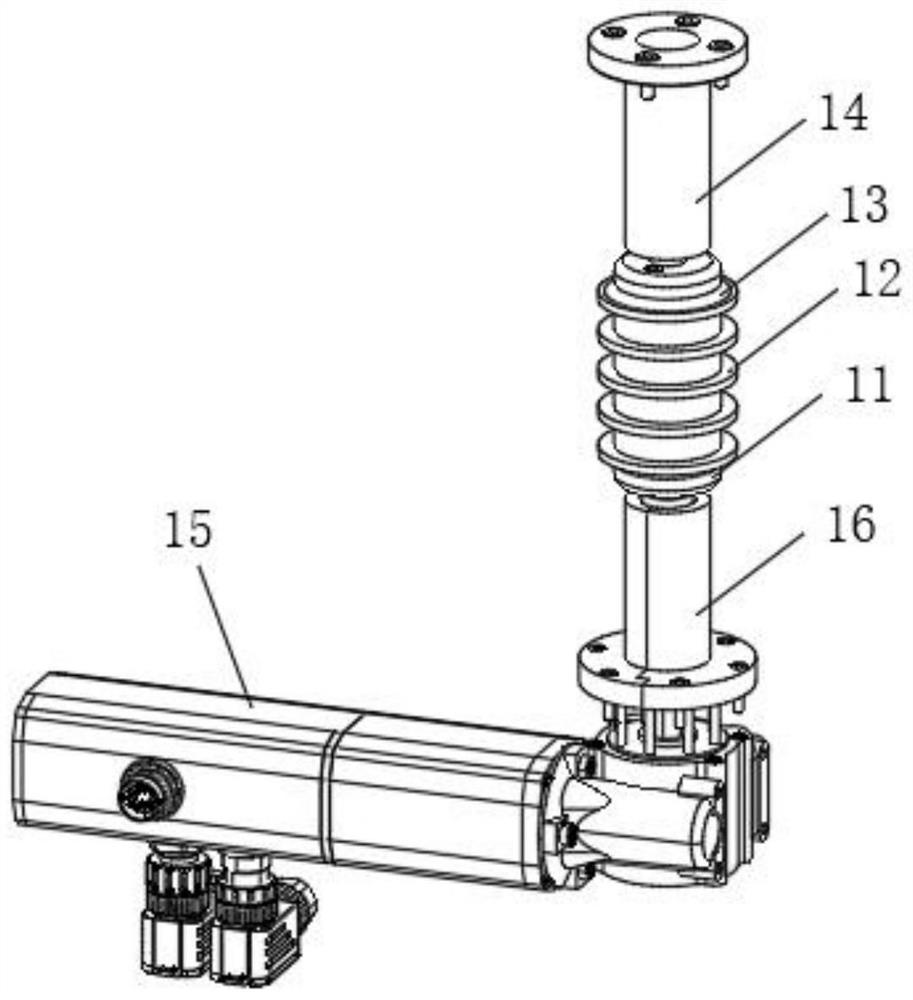

[0036] refer to Figure 1-4 As shown, a segmented control system for extremely low tow tension in a laying equipment includes:

[0037] Device main body 1;

[0038] Tension control mechanism, the tension control mechanism is arranged on the main body 1 of the equipment;

[0039] Tension reduction mechanism, the tension reduction mechanism is arranged on the main body 1 of the equipment, and is connected with the tension control mechanism through the tow;

[0040] Wherein, the device main body 1 is provided with an unwinding motor for tow unwinding;

[0041] The equipment main body 1 is provided with a material roll.

[0042] The control system adjusts the electronic pressure regulating valve according to the feedback signal, and repeatedly adjusts the tow tension to form a closed-loop system.

[0043] The tension control mechanism includes a tension support plate 9 installed on the main body 1 of the equipment, a cylinder 8 is provided on the tension support plate 9, an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com