Floating piston type buoyancy regulator and use method

A technology of floating pistons and regulators, which is applied to motor vehicles, special-purpose vessels, underwater operating equipment, etc., can solve problems such as unfavorable flexible layout of internal and external oil bags, low buoyancy adjustment control accuracy, and large structural limitations, etc., to achieve Avoid water pollution and corrosion, flexible layout relative position, good buoyancy adjustment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

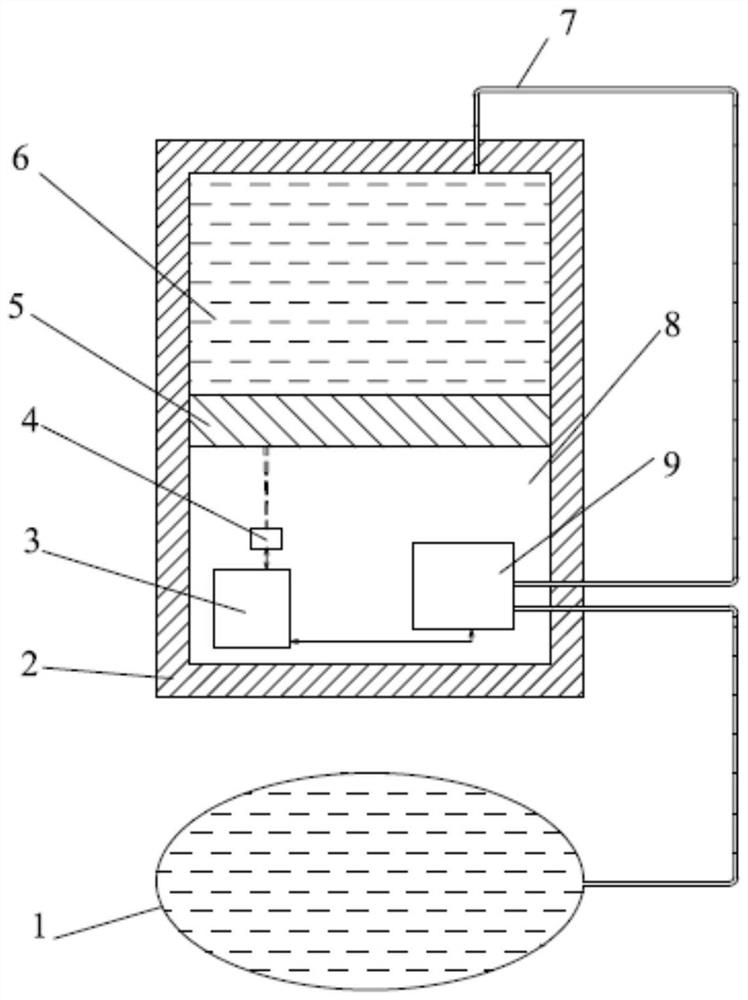

[0030] like figure 1 As shown, the floating piston buoyancy regulator includes a watertight pressure chamber 2 , a regulating pipe 7 and a hydraulic power system 9 .

[0031] A piston 5 is slidably fitted in the watertight pressure chamber 2 , and the piston 5 divides the watertight pressure chamber 2 into an inner liquid chamber 6 and a pressure air chamber 8 .

[0032] The inner liquid chamber 6 has a built-in buoyancy regulating medium, and the inner liquid chamber 6 communicates with the outside through the regulating pipe 7 , and the regulating pipe 7 is provided with the hydraulic power system 9 .

[0033] The pressure chamber 8 is provided with a displacement sensor for detecting the displacement of the piston 5 .

[0034] When in use, the buoyancy adjustment medium of the inner liquid chamber 6 is drawn out through the hydraulic power system 9 or the external buoyancy adjustment medium is drawn back into the inner liquid chamber 6, and the piston 5 slides back and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com