Long and thin centrifugal casting pipe shot blasting sand removing device and method suitable for production line

A technology of centrifugal casting pipe and cleaning device, which is applied in the direction of used abrasive processing devices, metal processing equipment, manufacturing tools, etc., can solve the problems of unsuitable and difficult to completely remove shot blasting sand, and reduce the floor space , to avoid process division processing, the effect of small environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

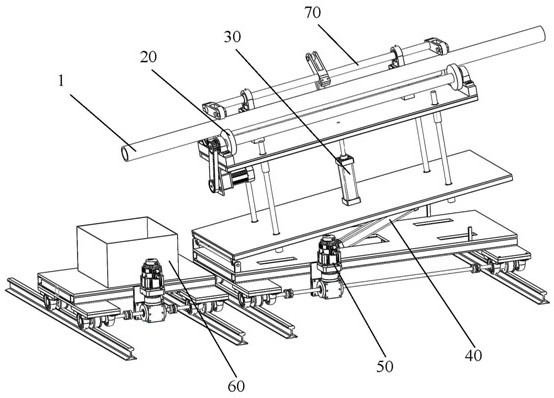

[0056] like Figure 3-8 As shown, the present application discloses a shot blasting sand removal device for elongated centrifugal casting pipes suitable for production lines, comprising a first guide rail 601 and a second guide rail 501, the first guide rail 601 and the second guide rail 501 are arranged in parallel, The first guide rail 601 is slidably provided with a recovery mechanism 60 for collecting shot blasting sand flowing out of the centrifugal casting tube. That is to say, the shot blasting sand removed from the centrifugal casting tube can be collected uniformly by the recovery mechanism, so as to prevent the shot blasting sand from falling on the ground, and at the same time facilitate the centralized treatment of the subsequent shot blasting sand.

[0057] Specifically, the recovery mechanism 60 includes a first bottom plate 602, the upper part of the first bottom plate 602 is provided with a recovery box 603 for collecting shot blasting sand, the first bottom pl...

Embodiment 2

[0068] like Figure 8 and Figure 9 As shown, the present application also discloses a method for removing shot blasting sand in a slender centrifugal casting pipe suitable for a production line, comprising the following steps:

[0069] S0. Each device is adjusted to the initial state, the tilting member is retracted, the tilting mechanism is in a horizontal state, the lifting mechanism is lowered, and the pressing mechanism is in an open state, and the centrifugal casting pipe is located on the shelf;

[0070] S1. After the components arranged on the second guide rail move to the feeding position along the second guide rail, the lifting mechanism lifts up the centrifugal casting tube and leaves the shelf, and then the lifting mechanism returns to the starting position along the second guide rail under the driving of the tilting mechanism. That is to say, at the beginning of the operation, the centrifugal casting tube is in the waiting position for feeding, and the pinch whee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com