Broaching surface quality evaluation method based on chip bending degree measurement

A bending degree and quality evaluation technology, applied in data processing applications, instruments, calculations, etc., can solve the problem of not paying attention to the correlation of chip shapes, and achieve the effect of convenient processing parameters, simple measurement, and easy tool change or adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings.

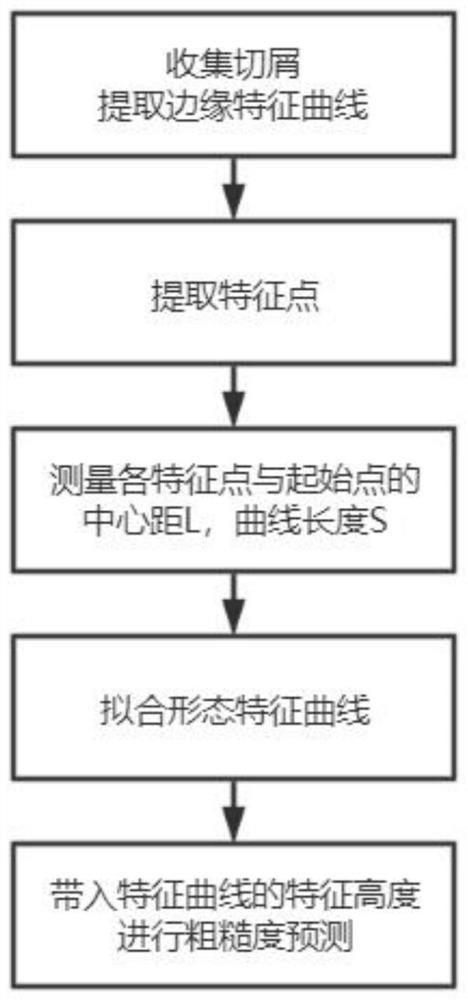

[0023] like figure 1 As shown, a method for evaluating the quality of a broached surface based on the measurement of the degree of chip bow includes the following steps:

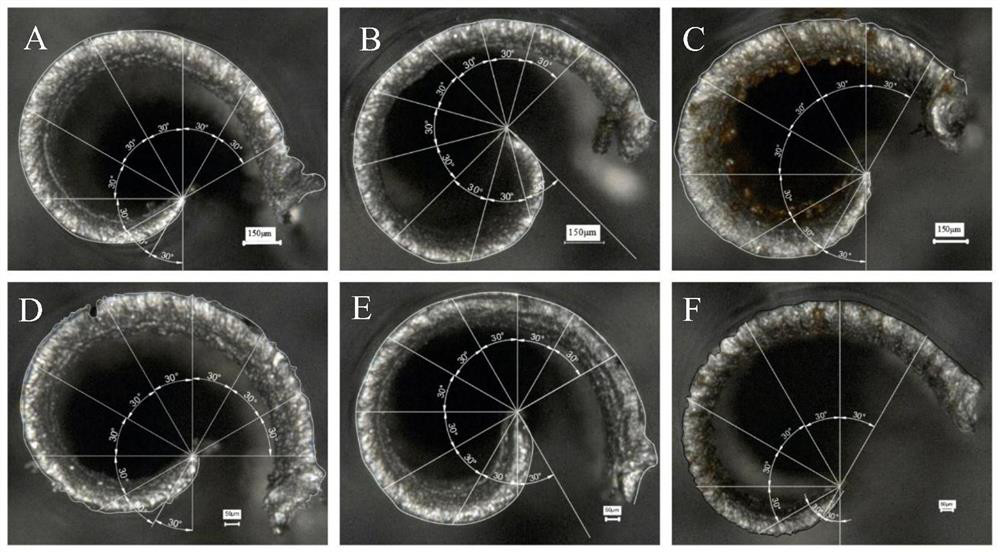

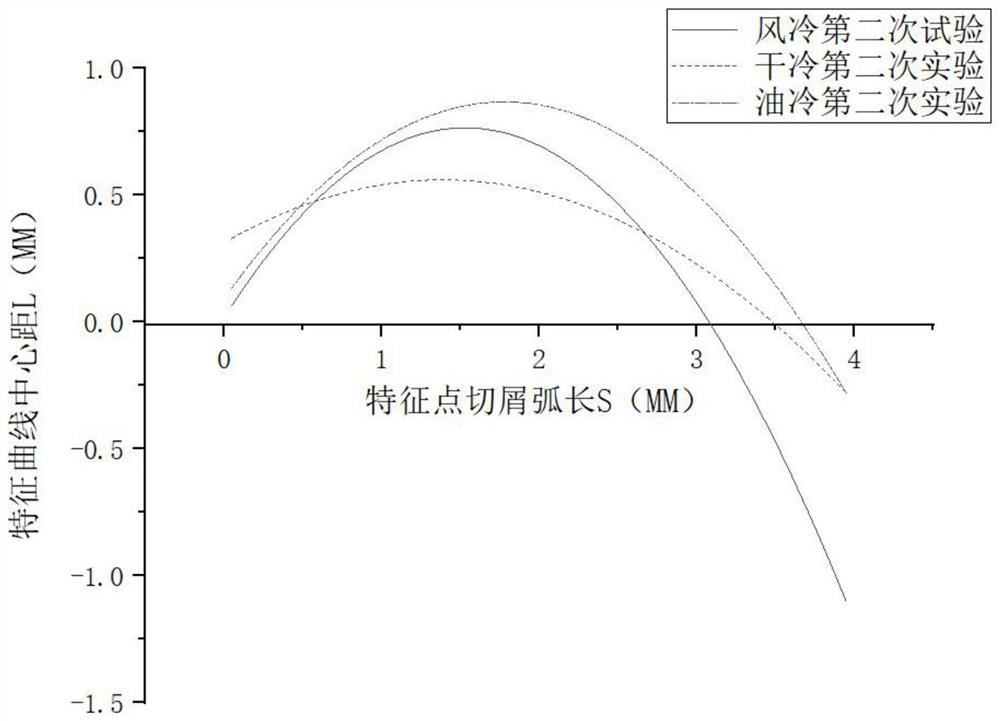

[0024] Step 1. In three different broaching environments, use the same broach to conduct a broaching test on the same workpiece. The conditions of the broaching test are: use a horizontal machine tool model LG612Ya-800 to perform broaching motion on the same workpiece with a lathe pulling force of 20KN and a broaching speed of 80mm / s in dry cutting, cold air, and oil-lubricated processing environments. , 3 replicate experiments were carried out in each working environment. The material of the workpiece is 45-gauge steel. The chips generated during machining are collected while the workpiece is being broached. SJ-210 surface roughness meter was used to measure the surface roughness of the workpieces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com