Optimal distribution method of steel scrap for steelmaking

A technology for scrap steel and steel grade, applied in data processing applications, forecasting, instruments, etc., can solve problems such as difficulty in effectively controlling smelting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

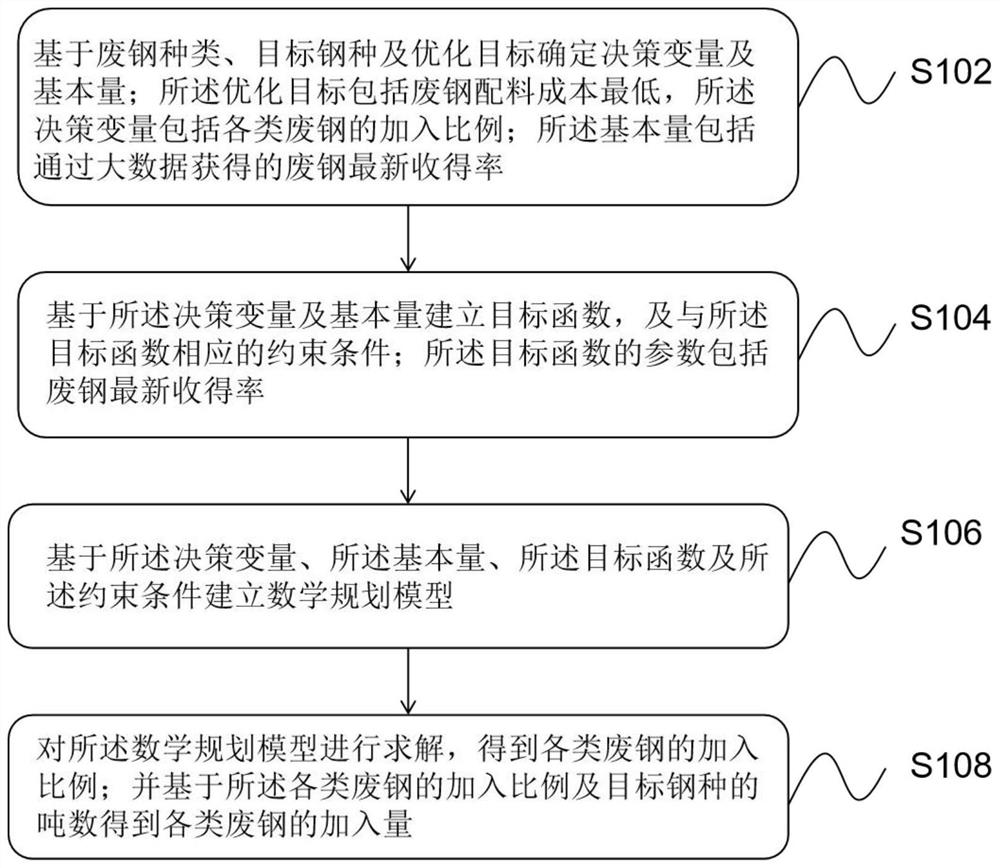

[0047] like figure 1 As shown, the optimal compounding method comprises the following steps:

[0048] S102. Determine a decision variable and a basic amount based on the type of scrap steel, the target steel type, and the optimization goal; the optimization goal includes minimizing the cost of scrap steel, and the decision variable includes the addition ratio of various types of scrap; the basic amount includes the use of big data The latest scrap yield obtained;

[0049] In this step, the decision variables and basic quantities are the basis for establishing a mathematical programming model. When determining the basic quantity, it is also necessary to consider the production plan and on-site conditions, such as comprehensive consideration of the material balance, energy balance, steelmaking process and equipment characteristics in the steelmaking process.

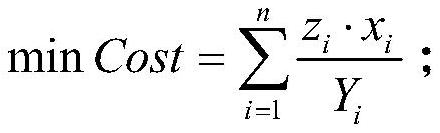

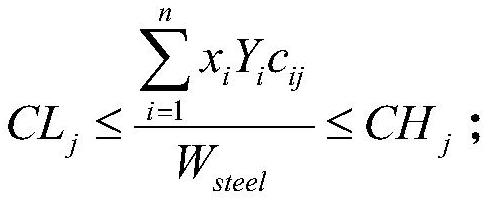

[0050] S104, establishing an objective function based on the decision variables and basic quantities, and constraints ...

Embodiment 2

[0081] According to the optimization method described in Example 1, the optimal allocation calculation is carried out for 80 tons of scrap steel for smelting 16Mn steel in an electric furnace, so as to reduce the cost of scrap steel per ton of molten steel. Specific steps are as follows:

[0082] First, based on the type of scrap steel - heavy waste and charge, shear waste and general waste, etc., the target steel type - 16Mn steel type, the optimization goal - the minimum cost of scrap steel batching, and comprehensively considering the 80-ton electric furnace production plan and on-site conditions, to determine decision-making variables It is the addition ratio of various types of scrap; the basic amount to determine includes: the latest scrap yield of scrap, unit price of scrap, inventory, total scrap loading, content of harmful elements; and the content of harmful elements of target steel grades, etc.

[0083] Among them, the harmful element content of the target steel gra...

Embodiment 3

[0098] According to the optimization method described in Example 1, the optimal allocation calculation is carried out for 120 tons of scrap steel for smelting 13Cr steel in an electric furnace, so as to reduce the cost of scrap steel per ton of molten steel. Specific steps are as follows:

[0099] First of all, based on the type of scrap steel - heavy waste and charge, shear waste and general waste, etc., the target steel type - 13Cr steel type, the optimization goal - the minimum cost of scrap steel batching, and comprehensively considering the 120-ton electric furnace production plan and site conditions, determine decision-making variables It is the addition ratio of various types of scrap; the basic amount to determine includes: the latest scrap yield of scrap, unit price of scrap, inventory, total scrap loading, content of harmful elements; and the content of harmful elements of target steel grades, etc.

[0100] Among them, the harmful element content of the target steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com