Fire-resistant furnace door with integral fiber process structure

A technology of fiber technology and refractory furnace, which is applied in the field of refractory furnace doors with integral fiber technology structure, which can solve the problems of frequent maintenance, high cost, and easy failure of fiber modules, so as to enhance the fire resistance and service life, and reduce the degree of repeated deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

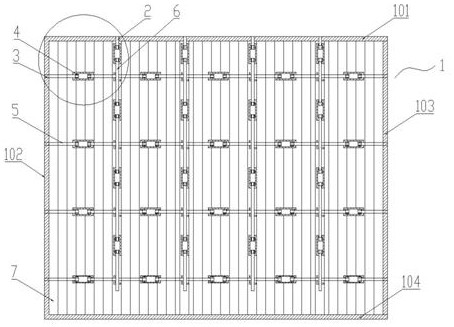

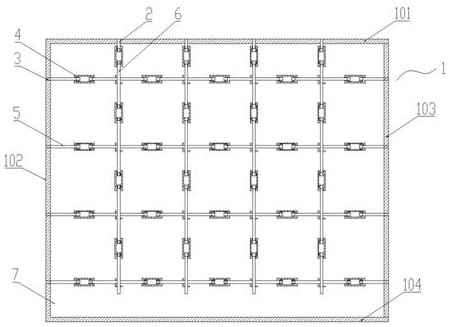

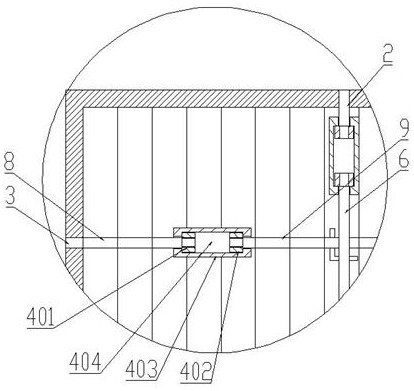

[0032] The present application will be further described in detail below with reference to the accompanying drawings. refer to Figure 1-5 , an integral fiber craft structure refractory furnace door, comprising a furnace door guard 1 and an anchoring mesh structure, the furnace door guard 1 and the anchoring mesh structure are equipped with an integral fiber module, and the integral fiber module includes a vertical Folding sheet units 7 arranged horizontally in sequence on the furnace door.

[0033] The folded sheet unit 7 is formed by folding the refractory fiber blanket in half. The material and model of the refractory fiber blanket can be selected according to the actual refractory requirements, such as the material of the ceramic fiber blanket. Filling starts from one side of the furnace door guard plate 1, and the entire row of folded sheet units 7 is assembled after horizontal and uniform compression.

[0034] The front and rear ends of the folded sheet unit 7 are the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com