Automatic lifting device

An automatic lifting and lifting mechanism technology, which is applied in the direction of hoisting device, winch device, loading/unloading, etc., can solve the problems of difficult targeted design, complex structure, limited application, etc. Tight function, guarantee the effect of safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the technical solutions and advantages of the present application clearer, the present application will be described in detail below with reference to the accompanying drawings and specific embodiments.

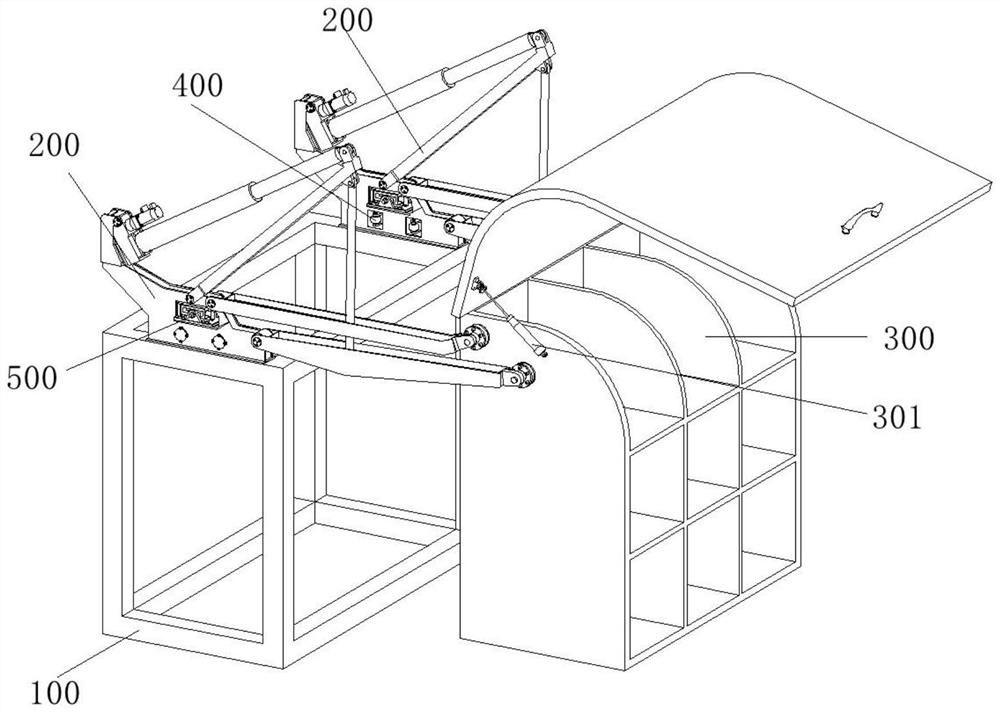

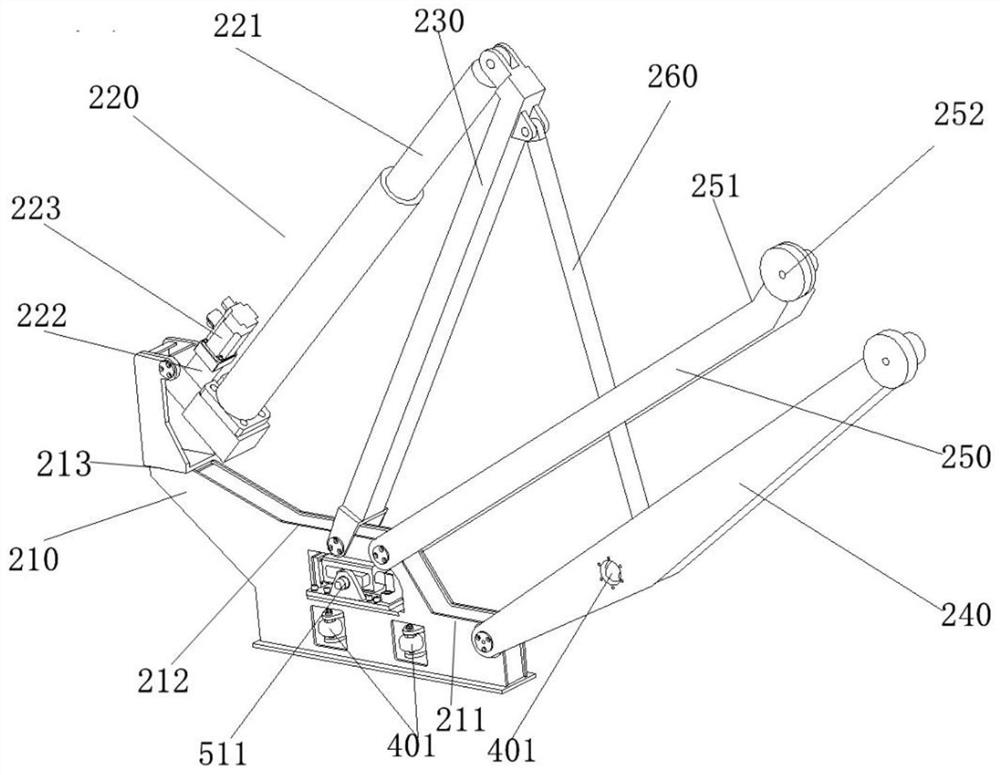

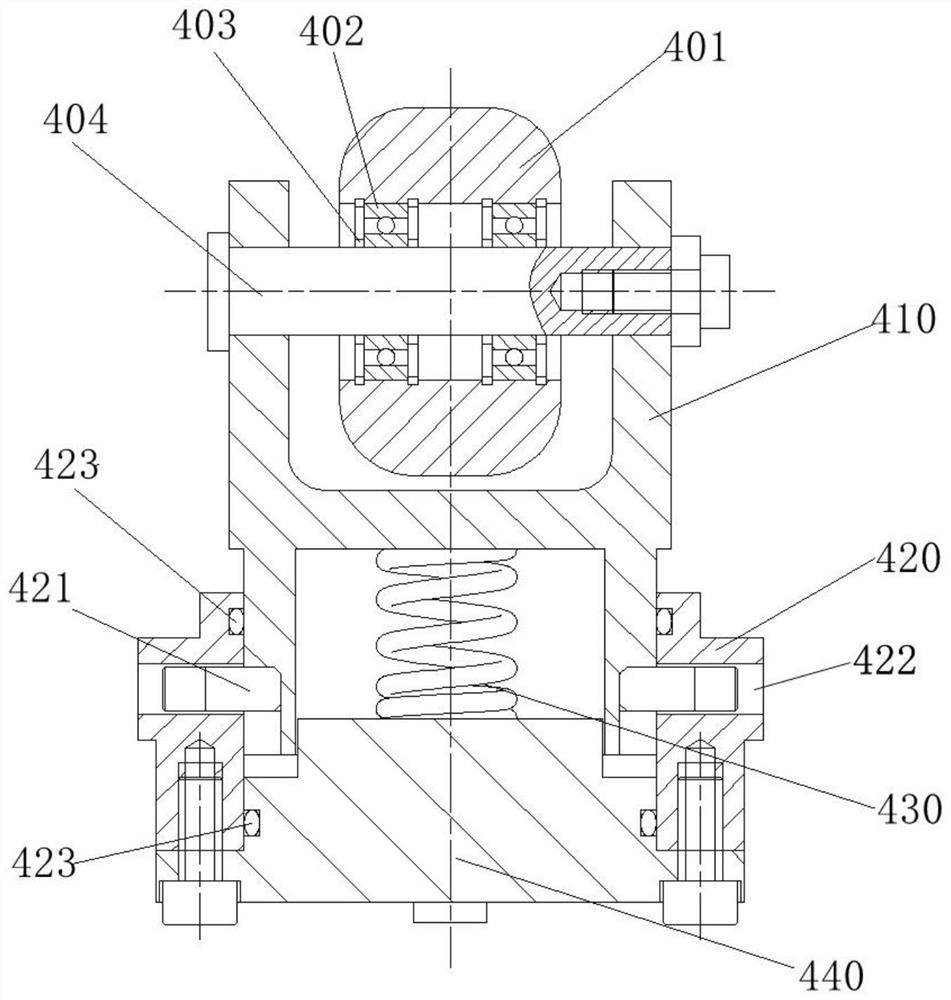

[0044] like Figure 1-2 As shown, an automatic lifting device of the present invention includes a base 100 , two sets of multi-link lifting mechanisms 200 and a warehouse 300 , wherein the two sets of multi-link lifting mechanisms 200 are respectively connected to both sides of the warehouse 300 , the multi-link lifting mechanism 200 includes:

[0045] a fixing seat 210, the fixing seat 210 is fixedly connected with the base 100;

[0046] a linear drive mechanism 220, one end of the linear drive mechanism 220 is hinged on the fixed seat 210;

[0047] a rocker 230, one end of the rocker 230 is hinged with the other end of the linear drive mechanism 220, and the other end of the rocker 230 is hinged with the fixing seat 210;

[0048] The main rod 240,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com