Device for manufacturing anti-scald pad from straw and manufacturing method of anti-scald pad

A technology of straw and straw fiber is applied in the field of daily necessities, which can solve the problems of not being utilized, inconvenient to use, and strong in thermal conductivity, and achieve the effects of resource saving, simple production process and high surface toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

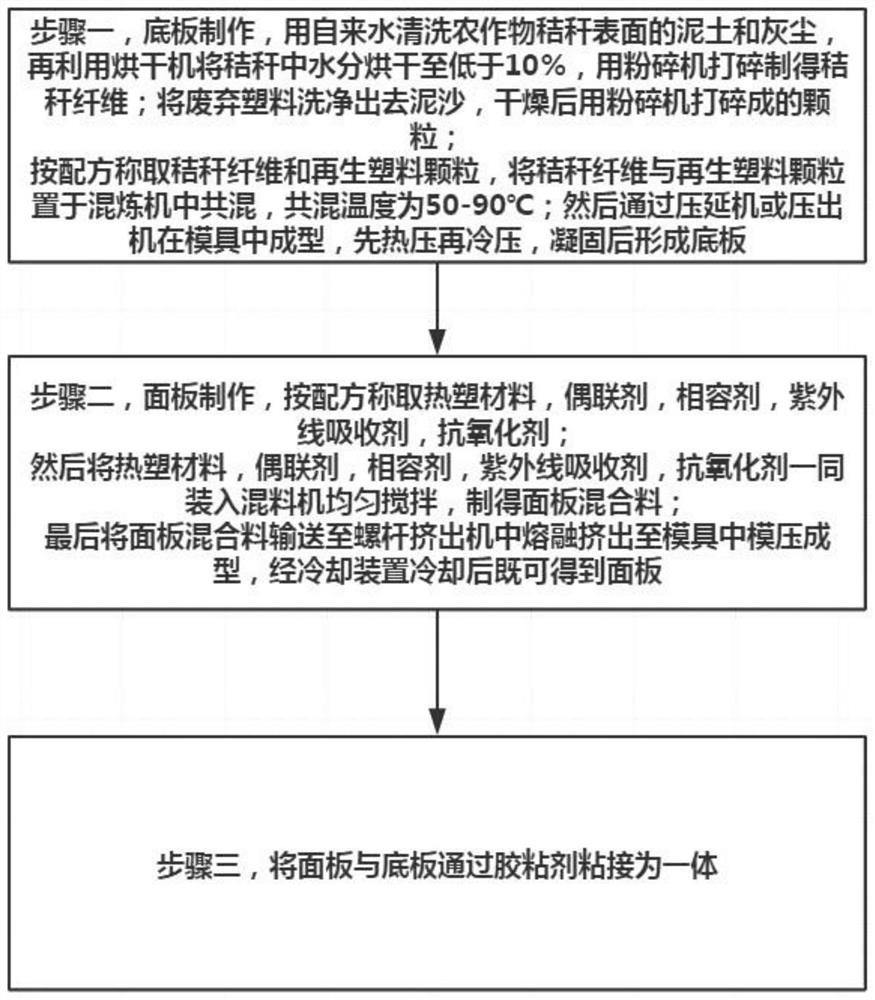

Image

Examples

Embodiment 1

[0031] The embodiment of the invention discloses an anti-scalding pad made of straw, comprising a panel and a bottom plate; the panel and the bottom plate are bonded together by an adhesive;

[0032] The panel includes the following components by weight: 60 parts of thermoplastic material, 2 parts of coupling agent, 0.5 part of compatibilizer, 2 parts of ultraviolet absorber, and 0.1 part of antioxidant; the bottom plate includes the following components by weight: 70 parts of straw fibers parts, 20 parts of recycled plastic pellets.

[0033] In order to further optimize the above technical scheme, the coupling agents include isobutyltriethoxysilane, γ-aminopropyltriethoxysilane, KH560 silane coupling agent, γ-methacryloyloxypropyltrimethoxysilane One or more of silanes.

[0034] In order to further optimize the above technical solution, the antioxidant is BHA antioxidant, BHT antioxidant or PG antioxidant.

[0035] In order to further optimize the above-mentioned technical ...

Embodiment 2

[0046] The embodiment of the invention discloses an anti-scalding pad made of straw, comprising a panel and a bottom plate; the panel and the bottom plate are bonded together by an adhesive;

[0047] The panel comprises the following components by weight: 70 parts of thermoplastic material, 2.2 parts of coupling agent, 0.6 part of compatibilizer, 4 parts of ultraviolet absorber, 0.3 part of antioxidant; the following parts by weight of the bottom plate; 75 parts of straw fiber , 25 pieces of recycled plastic pellets.

[0048] In order to further optimize the above technical scheme, the coupling agents include isobutyltriethoxysilane, γ-aminopropyltriethoxysilane, KH560 silane coupling agent, γ-methacryloyloxypropyltrimethoxysilane One or more of silanes.

[0049] In order to further optimize the above technical solution, the antioxidant is BHA antioxidant, BHT antioxidant or PG antioxidant.

[0050] In order to further optimize the above-mentioned technical scheme, the panel a...

Embodiment 3

[0061] The embodiment of the invention discloses an anti-scalding pad made of straw, comprising a panel and a bottom plate; the panel and the bottom plate are bonded together by an adhesive;

[0062] The panel includes the following components by weight: 80 parts of thermoplastic material, 2.5 parts of coupling agent, 0.8 part of compatibilizer, 6 parts of ultraviolet absorber, and 0.5 part of antioxidant;

[0063] The bottom plate includes the following components in parts by weight: 80 parts of straw fibers and 30 parts of recycled plastic particles.

[0064] In order to further optimize the above technical scheme, the coupling agents include isobutyltriethoxysilane, γ-aminopropyltriethoxysilane, KH560 silane coupling agent, γ-methacryloyloxypropyltrimethoxysilane One or more of silanes.

[0065] In order to further optimize the above technical solution, the antioxidant is BHA antioxidant, BHT antioxidant or PG antioxidant.

[0066] In order to further optimize the above-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com