A drive motor braking mechanism for cnc machining center

A brake mechanism and drive motor technology, which is applied to metal processing machinery parts, drive devices, metal processing equipment, etc., can solve the problems of excessive processing of materials and failure to stop rotation in time, and achieve the effect of avoiding excessive processing of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

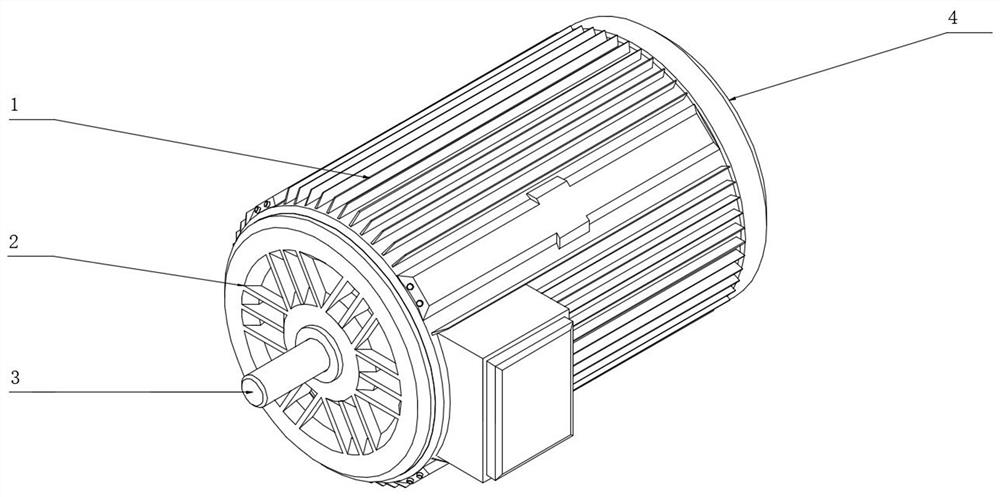

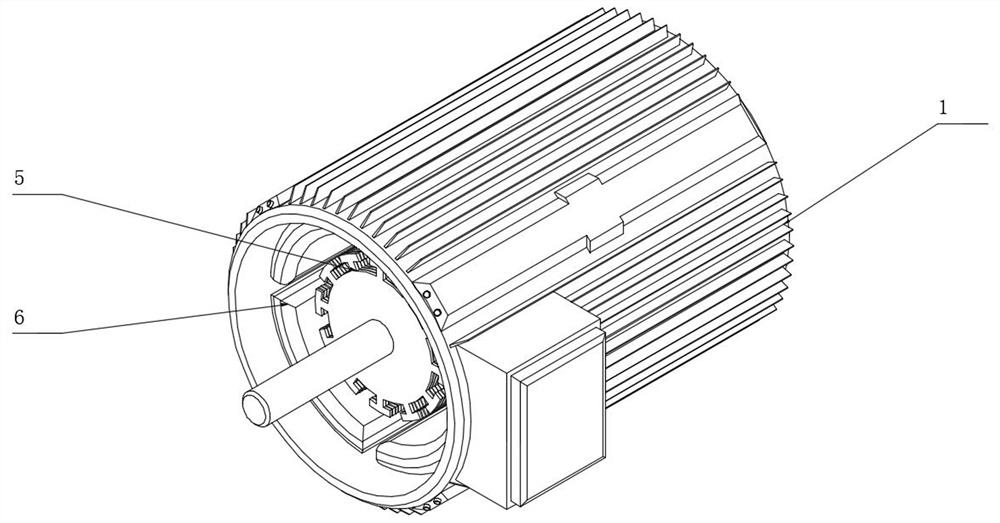

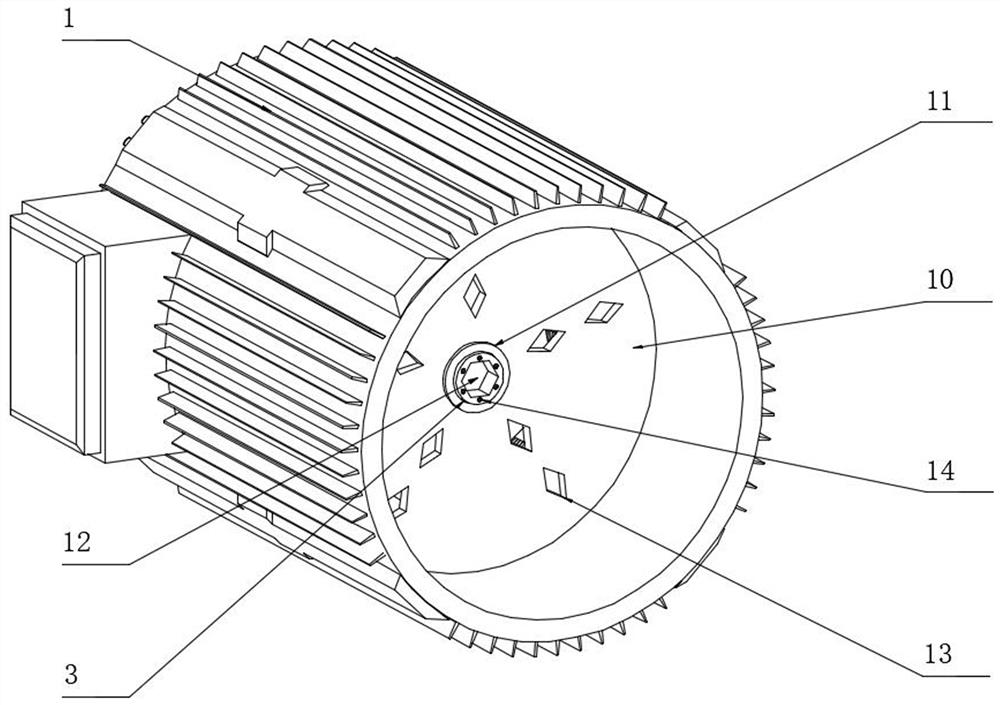

[0035] like figure 1 , 2, 3, 4, and 5, the embodiment of the present invention provides a drive motor braking mechanism for a CNC machining center, including a motor housing 1, and a stator 6 is fixedly installed inside the motor housing 1, and the stator 6 A rotor 5 is arranged inside the rotor 5, the rotor 5 is fixedly installed on the outer wall of the output shaft 3, and one end of the output shaft 3 is installed on the inner ring of the bearing 11, and the bearing 11 is fixedly installed at the center of the support plate 10, The support plate 10 is fixedly installed inside the motor housing 1, the other end of the output shaft 3 rotates through the front end cover 2 and extends to the outside of the front end cover 2, and the front end cover 2 is installed at one end of the motor housing 1, so the A rear end cover 4 is installed on the other end of the motor housing 1, and a driving device 7 is installed on the side surface of the rear end cover 4 close to the motor hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com