Biomass fuel forming and granulating device

A biomass fuel and granulation device technology, applied in the direction of waste fuel, fuel, solid fuel, etc., can solve the problems of reducing the quality of biomass fuel, inability to stir, poor crushing effect of biomass raw materials, etc., to improve efficiency and effect, The effect of improving the degree of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

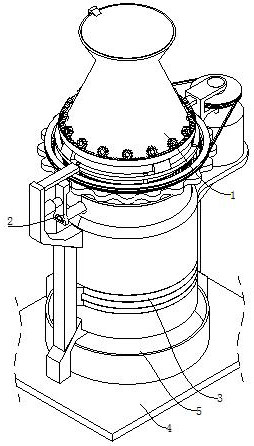

[0052] refer to figure 1 As shown, the biomass fuel molding and granulation device includes a pulverizing mechanism 1 for pulverizing and stirring biomass raw materials, and a drying mechanism 2 for stirring and drying biomass raw materials is provided on the lower side of the pulverizing mechanism 1, An extrusion granulation mechanism 3 is installed at the lower end of the drying mechanism 2, a base 4 is installed at the lower end of the extrusion granulation mechanism 3, and the upper end of the base 4 is located at the lower side of the discharge port of the extrusion granulation mechanism 3. Box 5.

[0053] Specifically, when the granulation production of biomass fuel is required, first, the biomass raw material to be pulverized is placed in the pulverizing mechanism 1, and the pulverizing mechanism 1 can pulverize the biomass raw material while stirring, thereby Increase the mixing uniformity of the biomass raw materials; then dry the biomass raw materials in the pulveri...

Embodiment 2

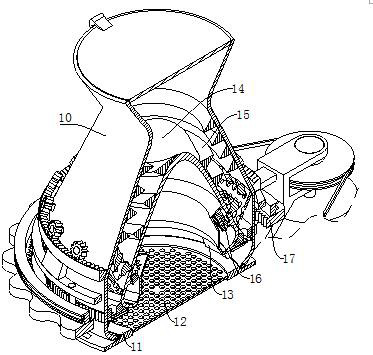

[0069] refer to Figure 7 As shown, on the basis of Embodiment 1, in order to improve the efficiency and effect of drying the raw materials, a drying mechanism 2 is provided; The reciprocating unit 20 is reciprocating. The lower end of the reciprocating unit 20 is installed with an exhaust duct 21 located on the lower side of the screening circular plate 12 and used to discharge hot air. The reciprocating unit 20 drives the exhaust duct 21 to perform reciprocating motion. The drying hood 22 is slidably arranged on the outer surface of the exhaust duct 21 and is rotatably connected with the support ring 11, and the drying hood 22 can be discharged from the exhaust duct 21. The hot air is limited; the drying cover 22 is provided with a stirring and discharging unit 23 for stirring and discharging the raw materials.

[0070] When the raw material needs to be dried, the exhaust pipe 21 is connected to the air outlet of the external hot air blower, and then the hot air blower can ...

Embodiment 3

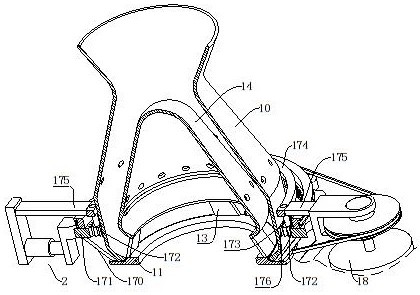

[0078] refer to Figure 9 and Figure 10 As shown in the figure, on the basis of the second embodiment, in order to be able to extrude and granulate the pulverized and dried raw materials, an extrusion granulation mechanism 3 is set at the lower end of the drying mechanism 2; The granulation mechanism 3 includes a support leg 30, a support column 31, a ring frame 32, a discharge through hole 33, a motor cylinder 34, a supporting ring plate 35, a hole blocking and cutting unit 36, a granulating circular plate 37 and a granulating unit 38, The upper end of the base 4 is provided with a plurality of support legs 30 that will not interfere with the moving process of the material box 5, so as to facilitate the picking and placing of the material box 5; the support legs 30 and the limit connecting plate 200 and the motor plate 185 above them There are supporting columns 31 between them, and the supporting columns 31 can increase the stability of the limit connecting plate 200 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com