TiAlMoNbW high-entropy alloy nitride film and preparation process thereof

A high-entropy alloy and preparation process technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems that limit the wide application of high-entropy alloy coatings, surface unevenness, and cladding layer cracking sensitivity Obvious and other problems, to achieve the effect of increasing strength and hardness, improving mechanical properties, and reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

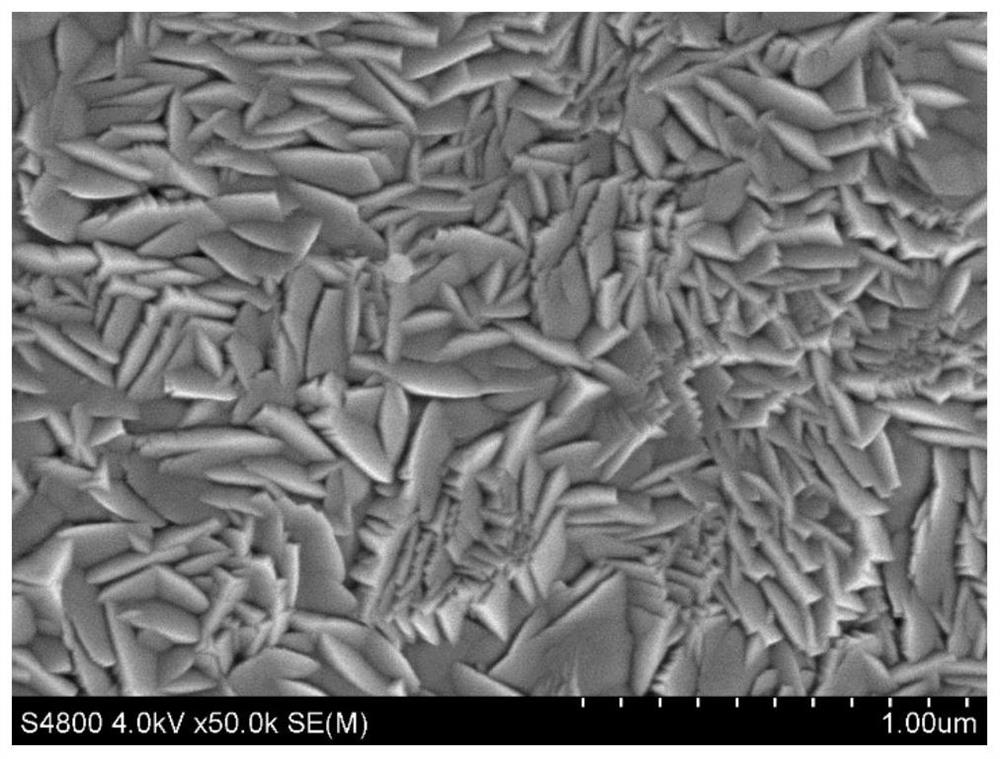

Image

Examples

Embodiment 1

[0041] 1. Prepare the target material: choose a disk-shaped TiAlMoNbW high-entropy alloy target containing five elements of Ti, Al, Mo, Nb, and W, and the atomic ratio of its constituent elements is Ti:Al:Mo:Nb:W=1:1 :1:1:1at.%. The diameter of the target is 101.6 mm, and the thickness of the target is 3 mm. The preparation of the target material in this embodiment specifically includes the following steps:

[0042] a. Prepare Ti, Al, Mo, Nb metal blocks, and W metal powder according to the composition ratio;

[0043] b. Master alloy refining:

[0044] b1. First add two metal blocks of Ti and Al with a melting point lower than 2000K and an atomic ratio of 1:1 for smelting to obtain a TiAl master alloy;

[0045] b2. Add Mo and Nb metal blocks with a melting point lower than 3000K with an atomic ratio of 1:1 for smelting to obtain a TiAlMoNb master alloy;

[0046] c. Preparation of TiAlMoNb master alloy powder: crush and refine the TiAlMoNb master alloy to obtain 150-300 mes...

Embodiment 2

[0066] 1. Prepare the target material: choose a disk-shaped TiAlMoNbW high-entropy alloy target containing five elements of Ti, Al, Mo, Nb, and W, and the atomic ratio of its constituent elements is Ti:Al:Mo:Nb:W=1:1 :1:1:1at.%. The diameter of the target is 101.6 mm, and the thickness of the target is 3 mm. The preparation of the target material in this embodiment specifically includes the following steps:

[0067] a. Prepare Ti, Al, Mo, Nb metal blocks, and W metal powder according to the composition ratio;

[0068] b. Master alloy refining:

[0069] b1. First add two metal blocks of Ti and Al with a melting point lower than 2000K and an atomic ratio of 1:1 for smelting to obtain a TiAl master alloy;

[0070] b2. Add Mo and Nb metal blocks with a melting point lower than 3000K with an atomic ratio of 1:1 for smelting to obtain a TiAlMoNb master alloy;

[0071] c. Preparation of TiAlMoNb master alloy powder: crush and refine the TiAlMoNb master alloy to obtain 150-300 mes...

Embodiment 3

[0088] 1. Prepare the target material: choose a disk-shaped TiAlMoNbW high-entropy alloy target containing five elements of Ti, Al, Mo, Nb, and W, and the atomic ratio of its constituent elements is Ti:Al:Mo:Nb:W=1:1 :1:1:1at.%. The diameter of the target is 101.6 mm, and the thickness of the target is 3 mm. The preparation of the target material in this embodiment specifically includes the following steps:

[0089] a. Prepare Ti, Al, Mo, Nb metal blocks, and W metal powder according to the composition ratio;

[0090] b. Master alloy refining:

[0091] b1. First add two metal blocks of Ti and Al with a melting point lower than 2000K and an atomic ratio of 1:1 for smelting to obtain a TiAl master alloy;

[0092] b2. Add Mo and Nb metal blocks with a melting point lower than 3000K with an atomic ratio of 1:1 for smelting to obtain a TiAlMoNb master alloy;

[0093] c. Preparation of TiAlMoNb master alloy powder: crush and refine the TiAlMoNb master alloy to obtain 150-300 mes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com