Natural gas liquid removal equipment and use method thereof

A technology of natural gas and equipment, applied in the field of natural gas liquid removal equipment, can solve the problems of reducing the specified value or safety value, not mentioning too much, and the separation efficiency of gravity sedimentation gas-liquid separator is limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

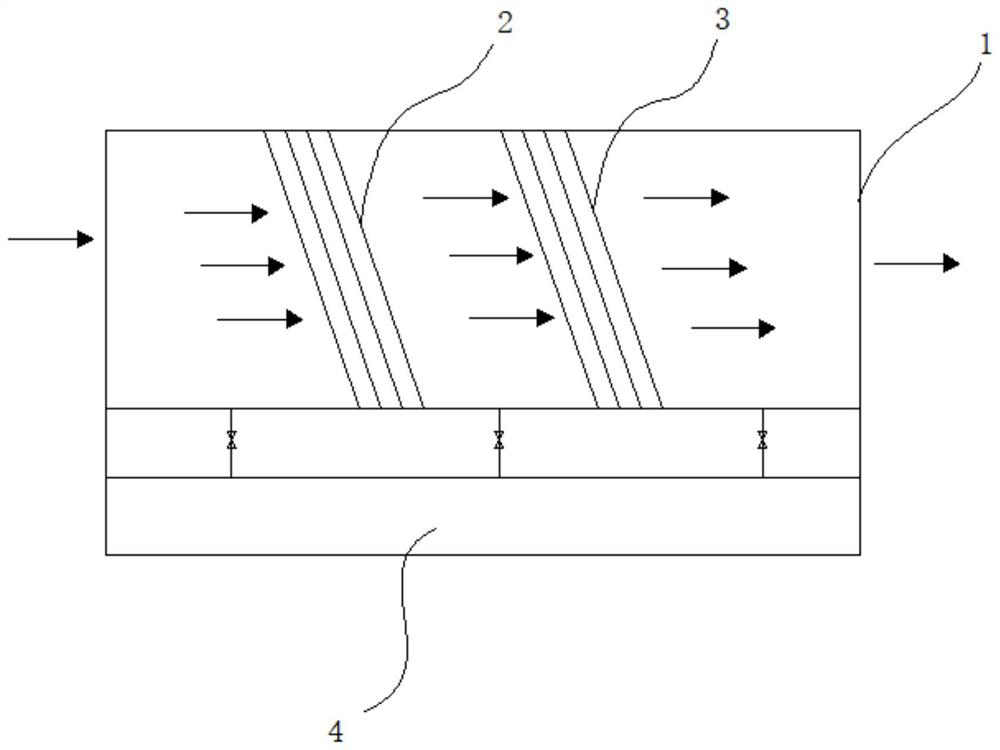

[0041] like figure 1 shown, figure 1 It is a schematic structural diagram of a specific embodiment of a natural gas liquid removal device provided by the present invention, and the direction of the arrow in the figure represents the gas flow direction of the natural gas to be treated.

[0042] The present invention provides a natural gas deliquoring device, comprising a casing 1 having a longitudinal length and a chamber inside, and two opposite ends of the casing 1 along the longitudinal direction are provided with an air inlet and an air outlet. A super-hydrophobic module and a super-oleophobic module are sequentially arranged in the chamber along the longitudinal direction, and the natural gas to be processed enters the chamber through the air inlet, and passes through the super-hydrophobic module and the super-hydrophobic module in sequence. The oleophobic module is discharged from the air outlet.

[0043] The liquid removal equipment provided by the present invention in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com