Distillation system and distillation method for producing super-superior alcohol by six-tower triple-effect differential pressure distillation

A distillation system, super-grade technology, applied in the field of alcohol production equipment, can solve the problems that the five-tower three-effect distillation process cannot adapt to the enterprise's quality improvement and consumption reduction, and high energy consumption, so as to achieve significant water and steam saving, product quality improvement, Obvious effect on product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

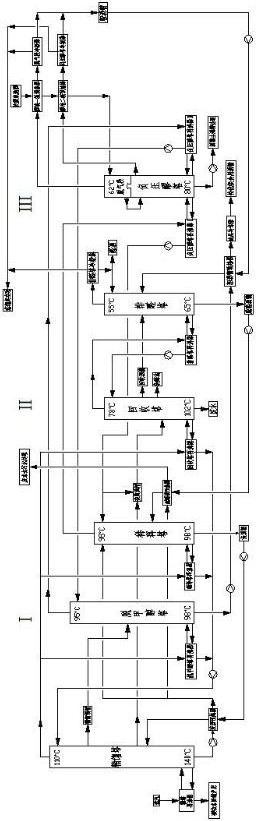

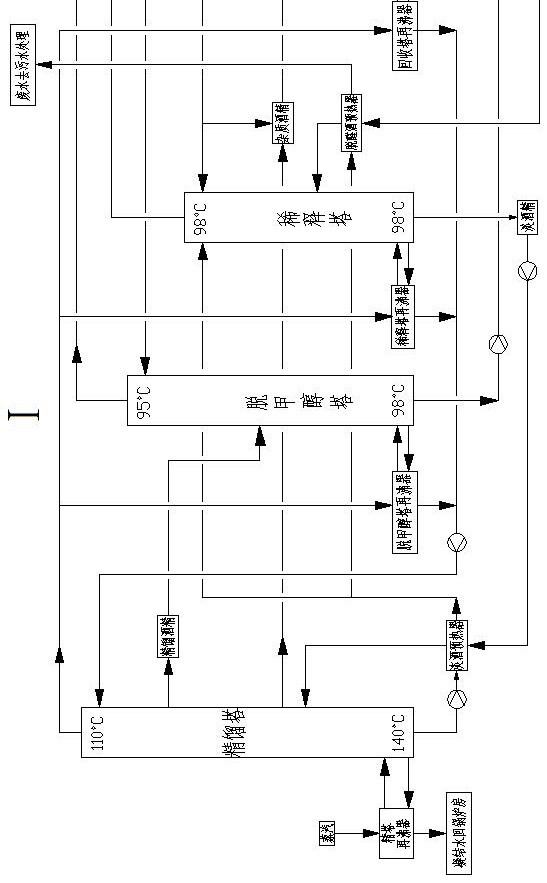

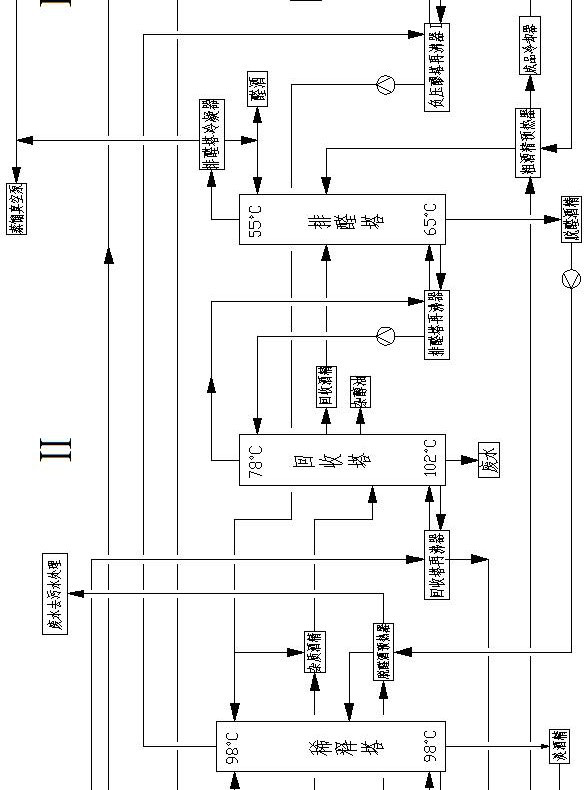

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

[0032] like Figures 1 to 4 Shown is a six-column three-effect differential pressure distillation to produce a distillation system of premium grade alcohol, including a negative pressure mash column, an aldehyde discharge column, a recovery column, a dilution column, a methanol removal column and a rectification column respectively connected with a reboiler The top of the negative pressure mash tower is provided with a degassing section, the bottom of the degassing section is connected with the working chamber of the negative pressure mash tower through an artesian pipeline, and the top of the degassing section is connected with a supply pipeline for fermentation and mature mash.

[0033] The crude alcohol outlet of the negative pressure mash tower and the crude alcohol outlet of the degassing section are connected with the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com