Water softener for dish-washing machine and dish-washing machine

A technology of water softener and dishwasher, which is applied in the washing machine/rinsing machine of tableware, parts and applications of washing machine/rinsing and rinsing machine of tableware, etc. It can solve the problems of affecting the washing effect, slow water intake, and poor control of water intake. Accurate and other issues, to achieve precise control of water intake, improve the washing effect, reduce the effect of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029]实施例一

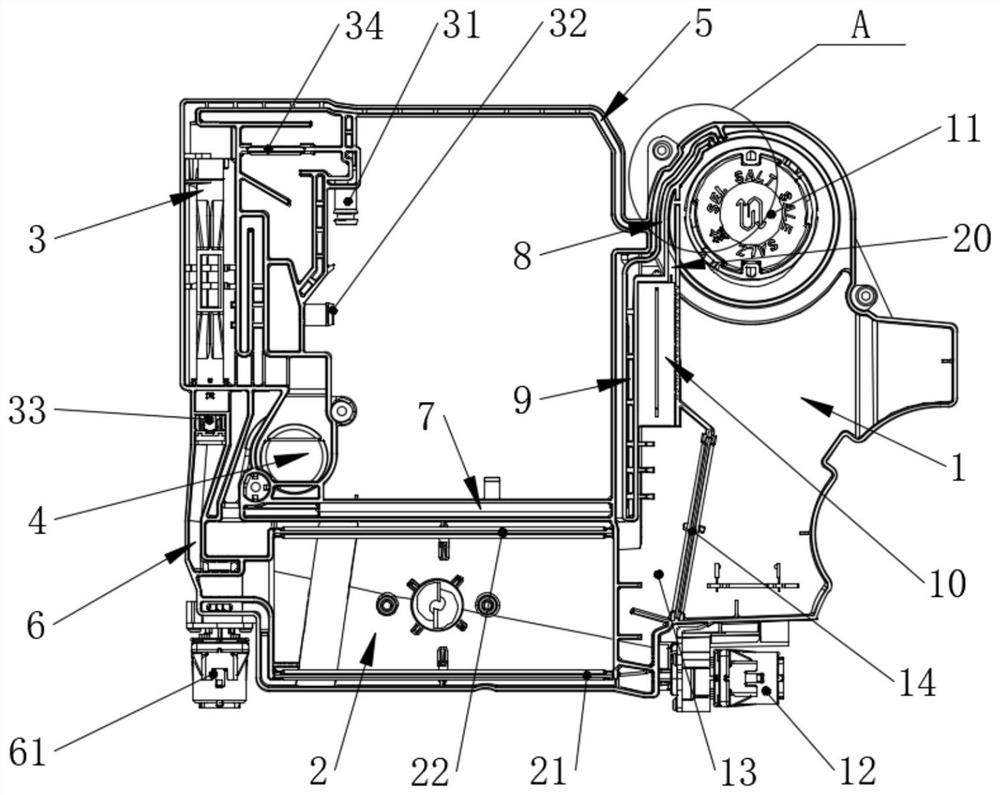

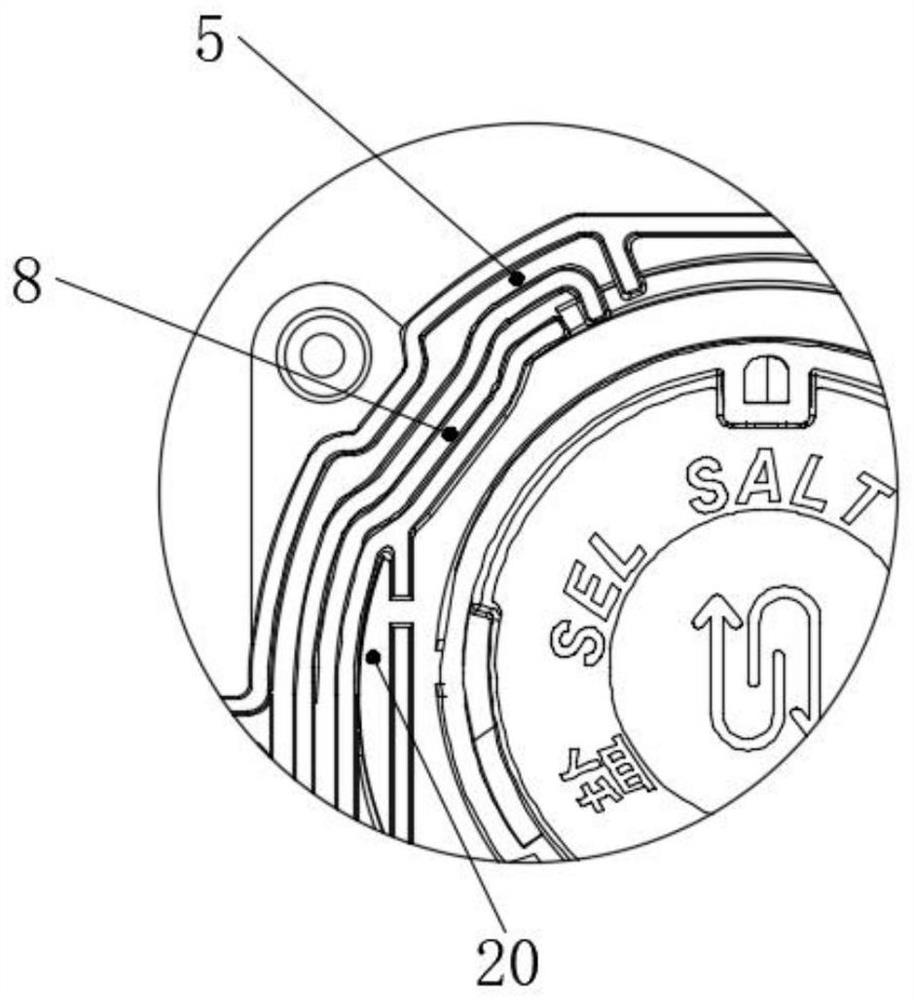

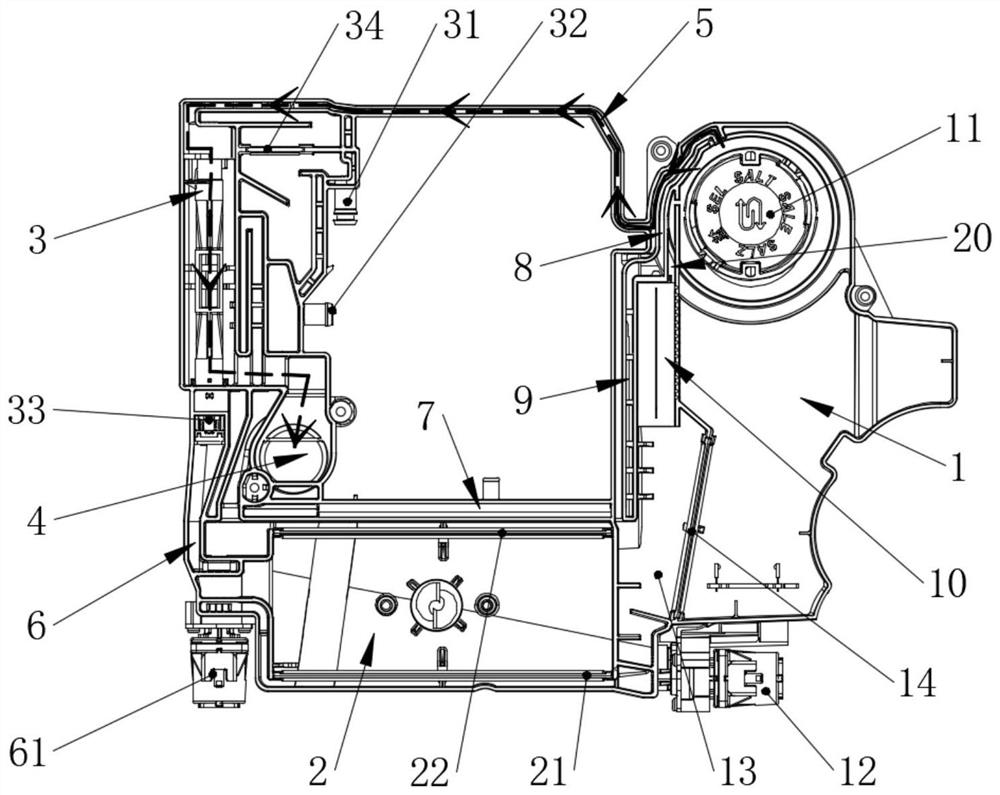

[0030]本实施例提供一种洗碗机用水软化器,其应用于洗碗机,能够实现高效的水软化,而且能够减少洗碗机洗涤过程中产生的水垢。如图1所示,该洗碗机用水软化器包括盐腔1、树脂腔2、进水通道3以及排气通道,其中:

[0031]上述盐腔1用于存储盐水,于盐腔1顶部设有加盐口11,通过该加盐口11能向盐腔1内加盐。该盐腔1底部连通于树脂腔2,且通过盐水泵12能够将盐腔1内的盐水输送至树脂腔2,以实现树脂腔2内树脂的再生。优选地,可以在盐腔1和树脂腔2之间设置一过渡腔室13,上述盐水泵12的进水端连通过渡腔室13,出水端连通树脂腔2,上述盐腔1连通过渡腔室13,且于过渡腔室13的连通位置处设置第一过滤网14,通过运行盐水泵12,盐腔1内的盐水会经第一过滤网14过滤后进入过渡腔室13,随后进入盐水泵12,并经盐水泵12输送至树脂腔2内。

[0032]上述树脂腔2用于存放水软化树脂,其能够将进入洗碗机的水进行软化,该树脂腔2的底部设有第二过滤网21,上述盐水泵12输送的盐水会经第二过滤网21进入树脂腔2。于树脂腔2的顶部还设有第三过滤网22,软化后的水经第三过滤网22进入洗碗机的内胆内。

[0033]上述进水通道3包括进水口31以及出水口32,其中进水口31可以和水源连接,出水口32则连接于洗碗机的内胆。如图1所示,该进水通道3的一端设有第一进水支路6和第二进水支路7,其中第一进水支路6连通于盐腔1,第二进水支路7连通于树脂腔2。通过该第一进水支路6,经进水口31进入进水通道3内的水能够由第一进水支路6流入盐腔1,以和盐腔1内的盐混合形成盐水。通过第二进水支路7,经进水口31进入进水通道3内的水能够由第一进水支路6流入树脂腔2,并被树脂腔2内的树脂软化,软化后的水经出水口32进入洗碗机内胆。本实施例中,在进水口31处还设有第四过滤网34,以过滤进入进水通道3内的水。

[0034]优选地,在第一进水支路6上设有再生阀61,通过该再生阀61,能够控制第一进水支路6的通断。

[0035]本实施例中,第二进水支路7一部分水平设置于树脂腔2上方,该结构的设置,能够减小第二进水支路7的占用空间,合理利用洗碗机用水软化器的有限空间。

[0036]优选地,进水通道3上设有连通第一进水支路6和第二进水支路7的分流阀33,通过该分流阀33,能够改变经进水口31进入进水通道3内的水的流向,...

Example Embodiment

[0048]实施例二

[0049]本实施例提供一种洗碗机,其包括内胆以及实施例一所述的洗碗机用水软化器,且该洗碗机用水软化器的溢水口连通于内胆,以便于向洗碗机用水软化器进水时,洗碗机用水软化器的腔体内的空气能排至内胆内。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com