Method for judging dry humidity of clothes used in washing machine and washing machine

A washing machine and dry humidity technology, which is applied to other washing machines, washing machine control devices, applications, etc., can solve the problems of low washing efficiency, increased water intake, fuzzy weighing, etc., and achieve improved judgment accuracy, simple structure, and improved accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

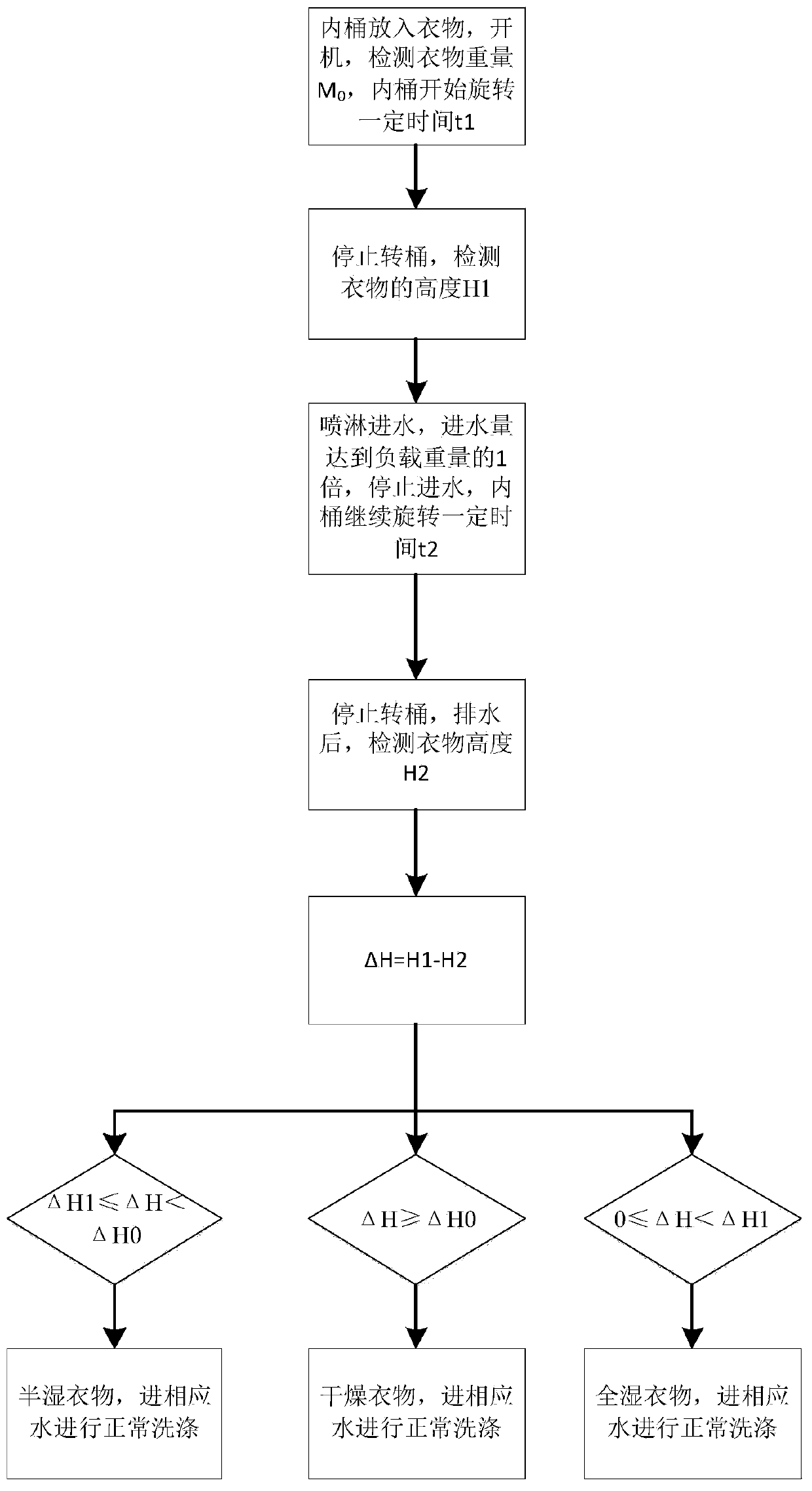

[0040] Such as figure 1 As shown, in this embodiment, a method for judging the dryness and humidity of clothes with a washing machine is introduced, which specifically includes the following steps:

[0041] Step 1), after putting the clothes in the inner bucket, control the inner bucket to rotate for a certain time t1, and evenly distribute the clothes;

[0042] Step 2), measure the weight and detect the height of the evenly distributed clothes, and obtain the quality M0 of the clothes put in and the height H1 of the clothes put in before the soaking procedure;

[0043] Step 3), perform the soaking procedure, spray water into the inner tub to make the clothes soaked; during the water inlet process and / or after the water inlet is completed, control the inner tub to rotate for a certain time t2 to evenly distribute the wet clothes, After the clothes are evenly distributed, drain all the water in the inner bucket;

[0044] Step 4), check the height of the evenly distributed and...

Embodiment 2

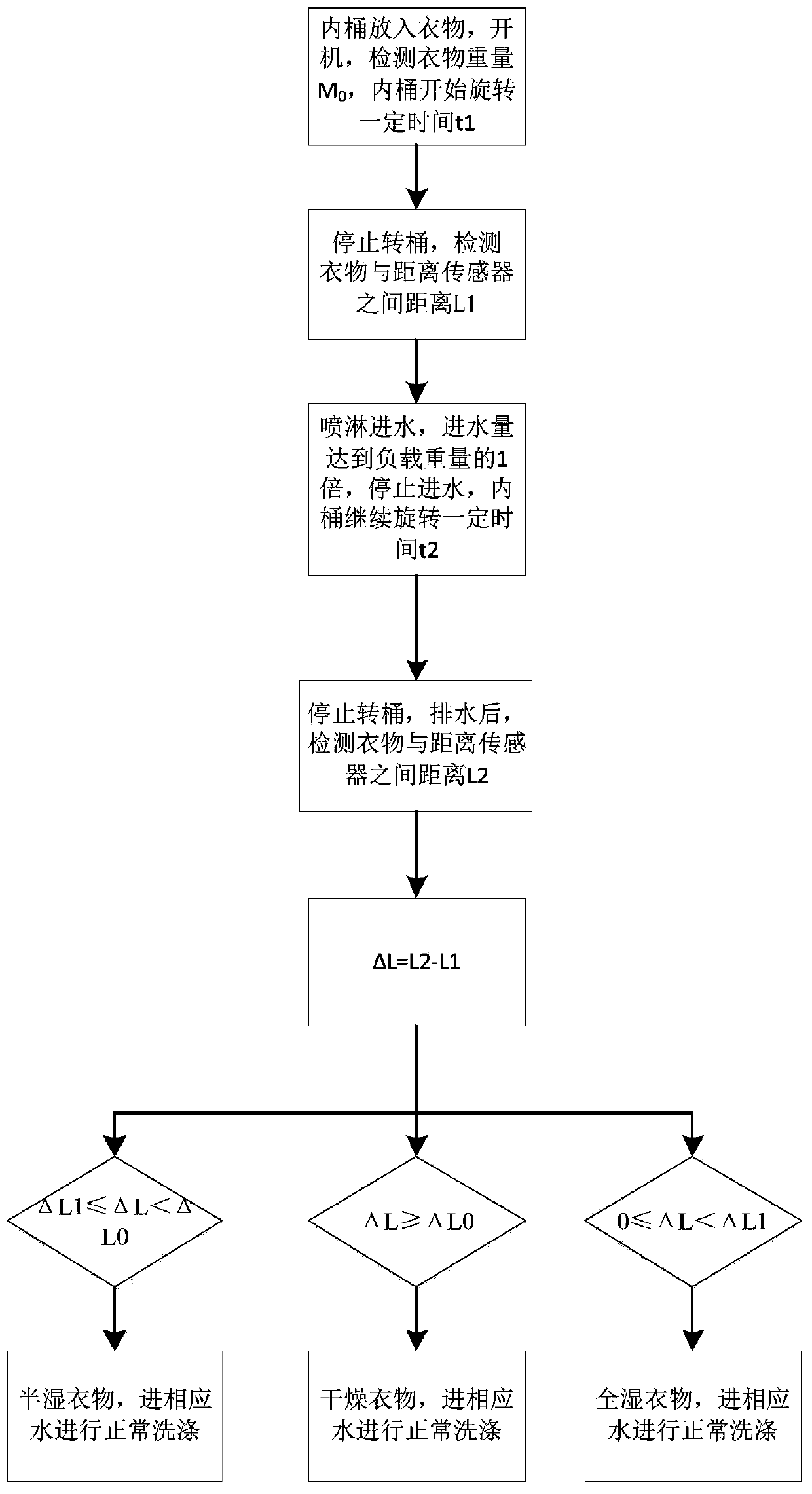

[0058] The difference between this embodiment and the above-mentioned embodiment 1 is that the distance difference between the upper surface of the clothes and the distance sensor before and after the soaking process of putting the clothes in the inner bucket is detected, and the distance difference is compared with the set value to obtain the clothes dry humidity.

[0059] By detecting the distance difference between the distance sensor and the upper surface of the clothes, the distance detected by the distance sensor can be directly measured to obtain the change in the height difference of the clothes in the inner bucket, which avoids the need to convert the detection value of the distance sensor into the height of the clothes. Therefore, compared with the first embodiment above, the control steps are simpler and the washing machine is more efficient in operation.

[0060] Such as figure 2 As shown, in this embodiment, a method for judging the dryness and humidity of cloth...

Embodiment 3

[0070] In this embodiment, the distance sensor is arranged on the top of the inner bucket, and the probe of the distance sensor sends out a detection grating to the bottom of the inner bucket in at least one direction, and the receiving end of the distance sensor can receive the detection grating reflected by the clothes put in the inner bucket. The light grid calculates the height of the laundry placed in the inner tub, and / or the distance between the distance sensor and the laundry placed in the inner tub.

[0071] Preferably, the distance sensor is installed on the control board of the washing machine above the inner tub, and the probe of the distance sensor emits a detection grating toward the inner tub. Further preferably, the probe of the distance sensor can be rotated and moved, so that the probe can emit detection gratings in multiple directions in the inner tub to detect the height of the clothes in the inner tub in multiple directions and / or the distance between the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com