Construction scheme for erecting self-standing lightning protection tower by combining built scaffold with external stay wire holding pole

A construction plan and scaffolding technology, applied in towers, buildings, building types, etc., can solve problems such as prolonged construction time, inability to reasonably arrange the overall project, and uncontrollable overall quality, and achieve the effect of ensuring construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

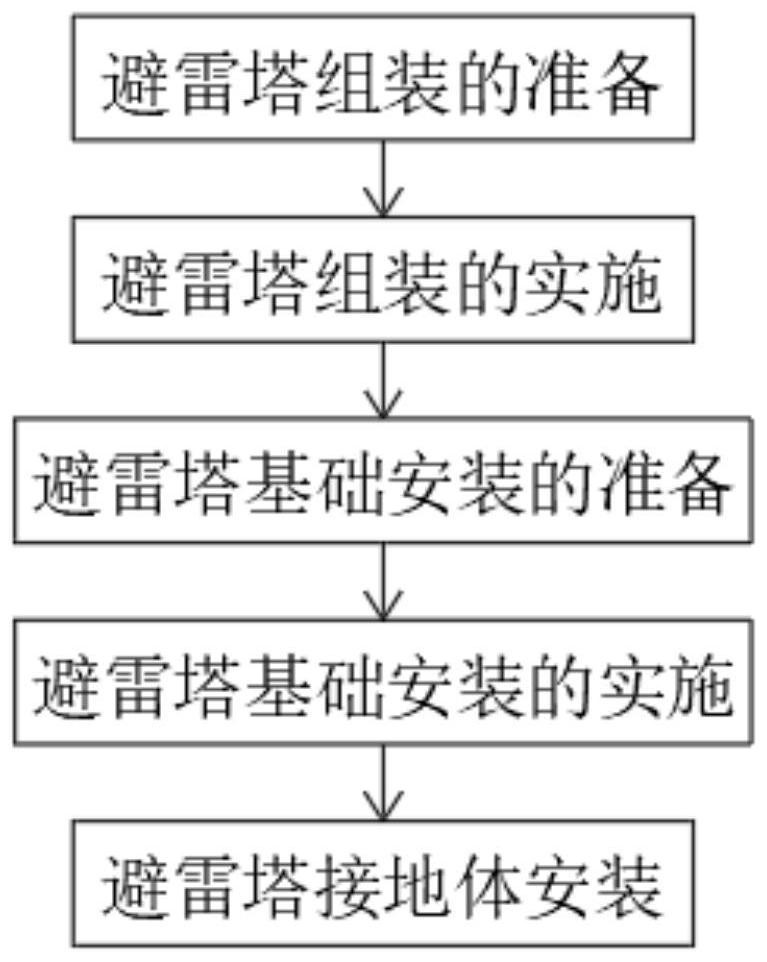

[0023] see figure 1 , the embodiment of the present invention provides a construction scheme for building a scaffolding combined with an external pulling wire and holding a pole to form a self-supporting lightning tower, including the following steps:

[0024] 1. Preparation of lightning tower assembly

[0025] A. Accept the work task, arrive at the lightning tower replacement site for actual investigation, understand the location of the site, and preliminarily formulate the layout of the construction site;

[0026] B. Formulate a construction plan according to the actual situation on site, and approve it by the leader of the unit (the contents include operation content, operation conditions, staffing, operation methods and preliminary preparations, etc.);

[0027] C. Preparation of tools. Prepare according to the construction content, construction method, etc., and prepare sufficient materials, have a certain number of spare tools and materials, and ensure the safety factor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com