Semiconductor thickness detection and comparison device

A technology of thickness detection and comparison device, which is applied in semiconductor/solid-state device testing/measurement, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effects of avoiding inaccurate detection results, improving work efficiency, and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

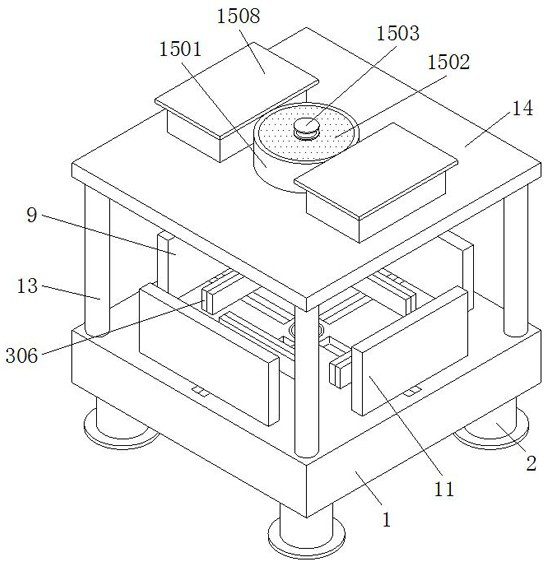

Image

Examples

Embodiment

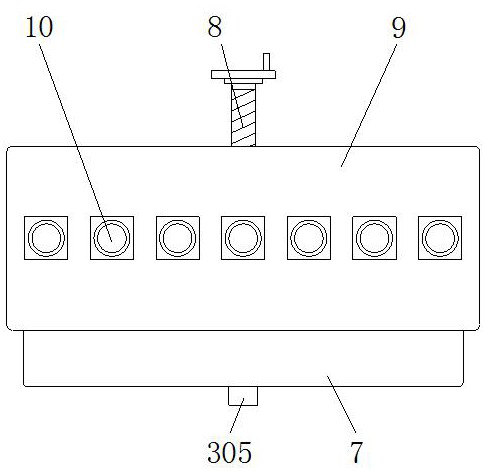

[0035] This ensures the stability of the bonding state of the connecting scraper rod 1506 on the filter screen plate 1502, thereby ensuring the automatic stability of the follow-up push and collection of dust and impurities, thereby ensuring the accuracy and safety of the follow-up detection work.

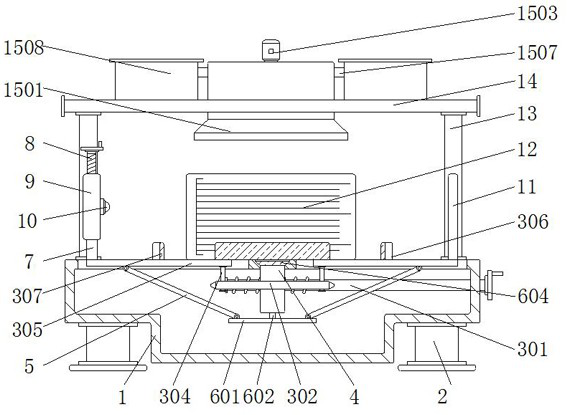

[0036] It should be noted that the present invention is a semiconductor thickness detection and comparison device. First, the staff can place the semiconductor that needs to be tested and compared on the workbench 1, and then the staff can rotate the worm 301. At this time, the worm 301 Under the action of rotation, the worm wheel 302 that is meshed and connected can be driven to rotate stably on the fixed pipe 4. At this time, during the rotation of the worm wheel 302, combined with the limit guide action of the limit plate 305, each guide groove 303 can drive the corresponding guide. The limiting plates 305 on the rod 304 move to the middle at the same time. At this time, under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com