A full gear transmission silage machine

A technology of gear transmission and silage machine, which is applied in the direction of agricultural machinery and tools, cutting equipment, application, etc., can solve the problems of labor, low machine utilization, machine turning and empty travel, etc., and achieve good product performance stability and transmission The effect of excellent efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

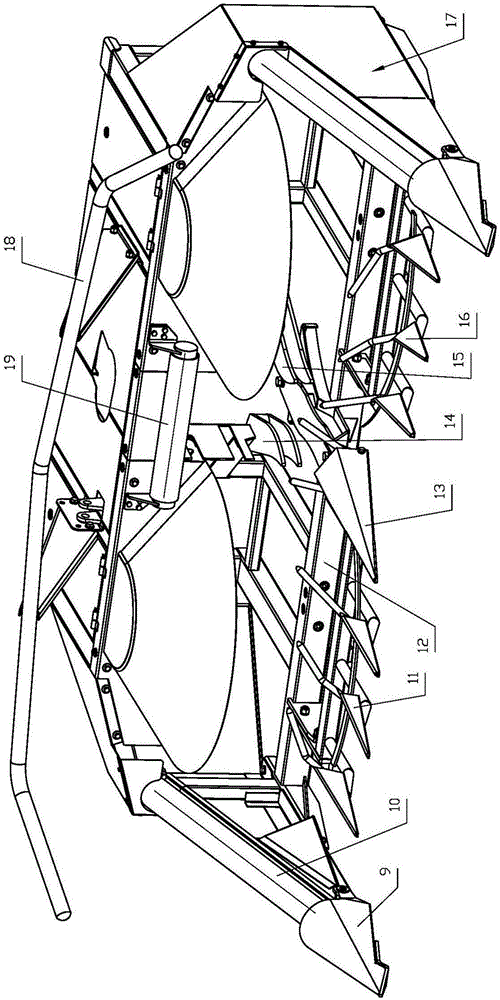

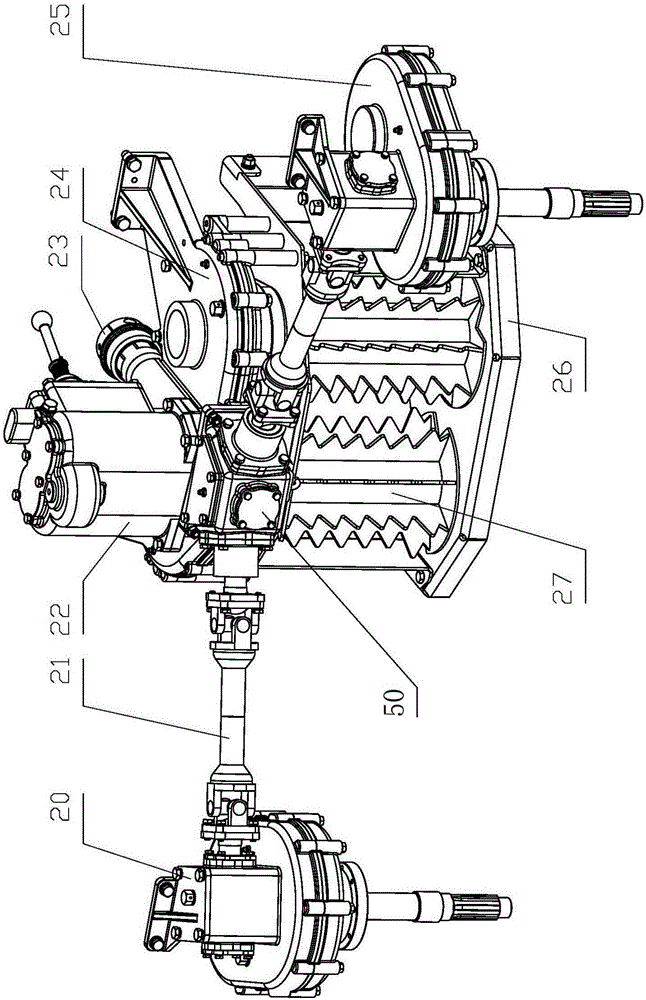

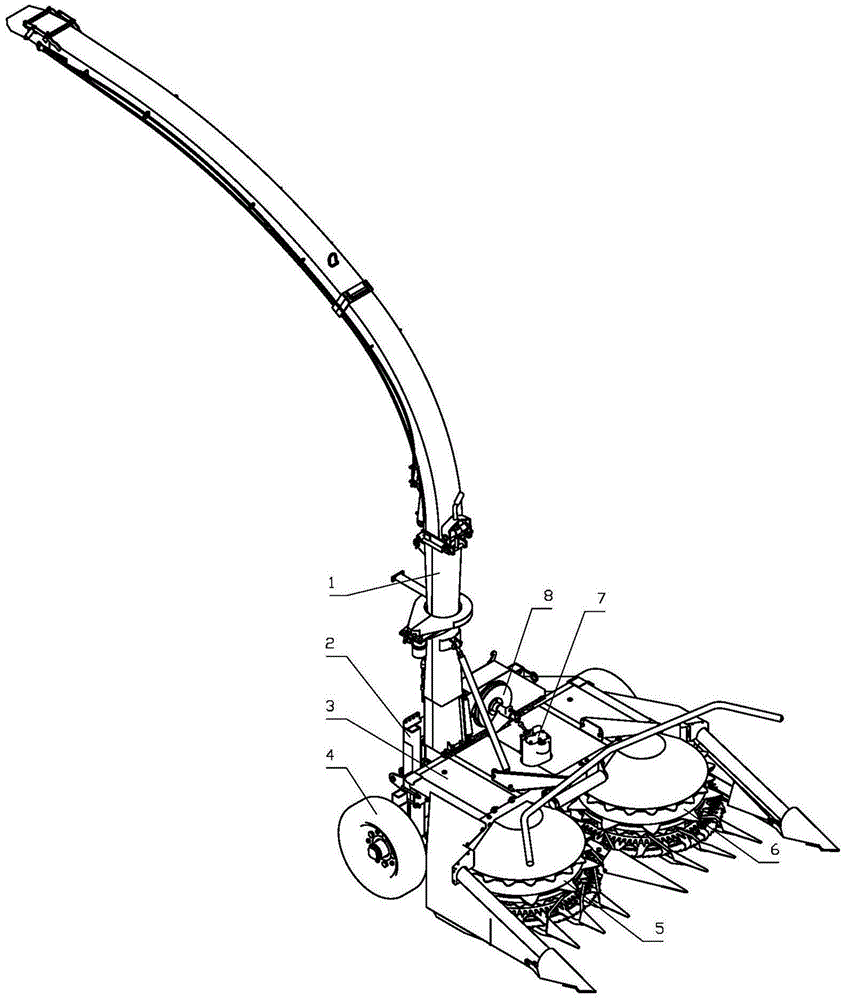

[0031] Embodiment 1: a kind of full gear transmission silage machine, its structure is as Figure 1-8 As shown, it includes throwing assembly 1, chopping assembly 2, frame assembly 3, support wheel assembly 4, right roller assembly 5, left roller assembly 6, feeding assembly 7, knife sharpening assembly 8 and multiple parts of the hydraulic system assembly.

[0032] Described frame assembly 3 comprises frame 12, and guard cover 17 is fixed on the frame 12, plays the effect of safety protection; Both sides of frame 12 are respectively equipped with crop divider 9, and the bottom of frame 12 is connected with respectively. The left splitting fork 16, the right splitting fork 11 and the middle splitting device 13 are connected, and they can divide the crops during work; the two splitting forks can guide and assist the cutting of the crops entering the working area. The material can enter the conveying process smoothly; the middle grain divider 13 plays a guiding role for the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com